Leave Your Message

As the world increasingly shifts towards sustainable energy solutions, the demand for advanced battery technologies is surging, particularly in the electric vehicle (EV) market. A recent report by IDTechEx suggests that the global demand for lithium-ion batteries could exceed 2,000 GWh by 2025, highlighting the critical need for innovative manufacturing methods to meet this challenge.

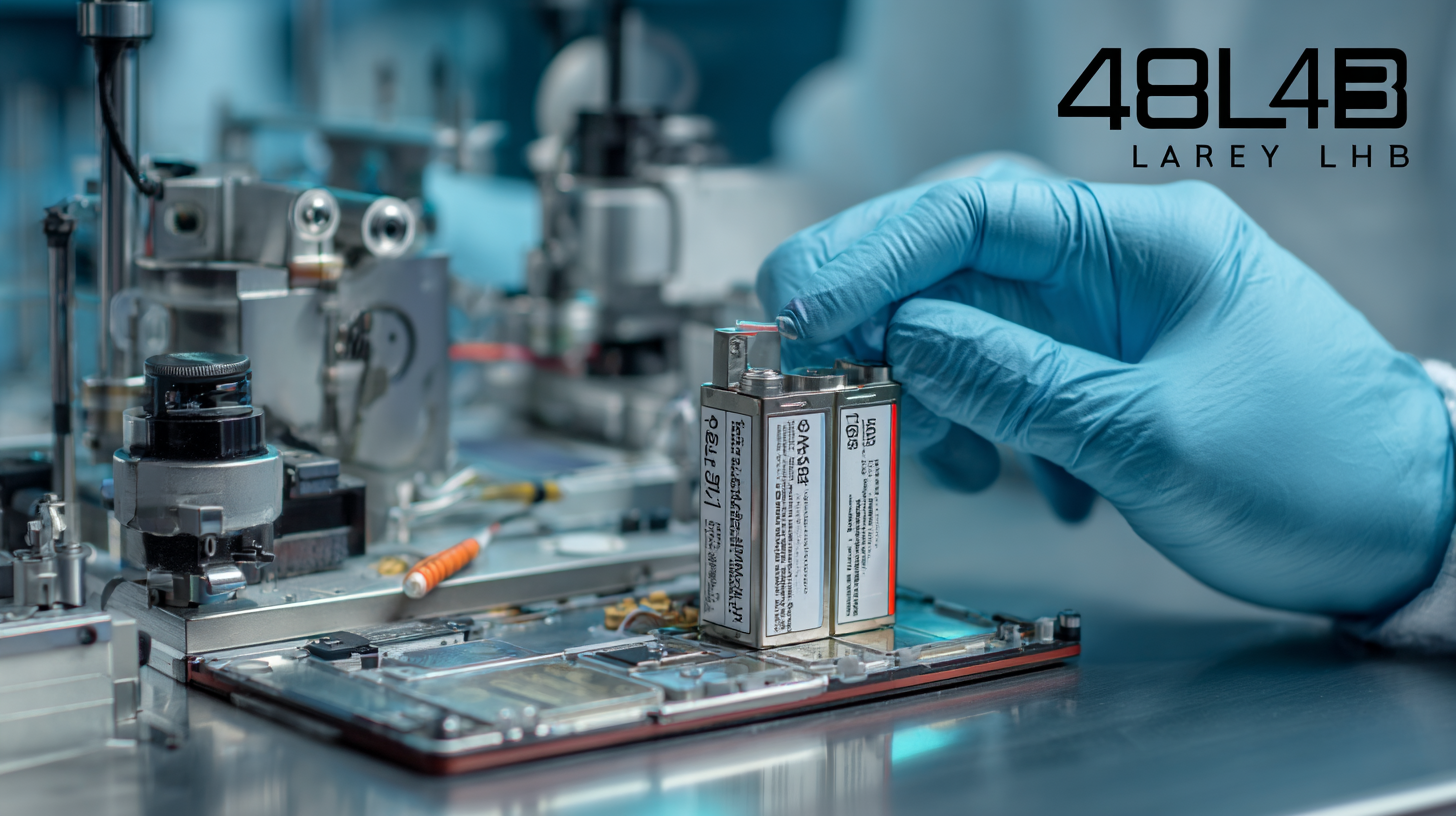

Among the most promising advancements is the 4680 Tabless Battery Lab Line, which offers significant improvements in energy density and manufacturing efficiency. These solutions, hailing from top-tier Chinese factories, are poised to revolutionize the battery industry by reducing production costs and enhancing performance.

As companies strive to establish trust on a global scale, the 4680 Tabless Battery Lab Line stands out as a testament to cutting-edge technology and the potential for increased reliability in battery production.

The emergence of 4680 tabless battery technology is set to revolutionize electric vehicles (EVs) by addressing some of the biggest challenges in battery performance and efficiency. One significant advantage of this design is the reduction in manufacturing complexity. The tabless architecture eliminates the need for traditional tabs, which simplifies the production process and enables faster assembly lines. This streamlined manufacturing can lead to decreased costs and improved scalability, making EVs more accessible to consumers.

Additionally, the 4680 tabless battery enhances energy density and thermal efficiency. By allowing for a continuous path for the current, this technology minimizes resistance and heat generation, leading to better overall performance. With a more compact design, these batteries can store more energy while occupying less space, which translates to extended driving ranges and reduced weight for vehicles. As automakers increasingly prioritize range and efficiency, the adoption of tabless batteries could play a crucial role in the wider acceptance and success of electric vehicles in the near future.

The emergence of the 4680 tabless battery design marks a significant shift in the electric vehicle (EV) battery landscape, offering compelling advantages over traditional cylindrical battery designs. Unlike conventional batteries that require multiple components to connect cells, the tabless design enhances the flow of electricity throughout the cell, reducing the internal resistance. This innovation not only boosts energy efficiency but also promises faster charging times and reduced costs in manufacturing.

A comparative analysis reveals that the 4680 tabless structure could lead to more compact and lightweight battery packs, crucial for improving the overall efficiency of EVs. In contrast, traditional batteries often compromise on space and weight due to their complex assembly. As leading companies race to develop advanced battery technologies, the performance and safety of the 4680 design are under scrutiny. It’s essential to focus on how its advantages in thermal management and safety compared to conventional designs can play a pivotal role in shaping the future of sustainable transportation. The ongoing research and comparisons among various battery solutions will determine which designs will ultimately be adopted for next-generation electric vehicles.

The year 2025 is projected to be a significant milestone for 4680 battery technology, which is rapidly evolving in the electric vehicle (EV) market. As automakers push for higher energy density, shorter charging times, and lower production costs, the advantages of tabless battery manufacturing solutions are becoming increasingly apparent. These innovations in design not only simplify the production process but also enhance the performance and longevity of batteries, making them a game-changer for electric vehicles.

Market projections indicate that the demand for 4680 batteries will skyrocket as more manufacturers adopt this technology. With a focus on sustainability and efficiency, companies are exploring ways to integrate 4680 batteries into their lineups. This shift is expected to drive down costs and improve accessibility, ultimately leading to a more significant market penetration of electric vehicles. As we approach 2025, the ongoing advancements in 4680 battery technology promise to reshape the automotive landscape, ensuring a cleaner and more efficient future for transportation.

As the world races towards a more sustainable future, the focus on battery technology, particularly the innovative tabless battery design, becomes imperative. The 4680 tabless battery, with its unique structure, eliminates the need for traditional tabs, leading to significant improvements in energy density and efficiency. This manufacturing innovation holds the promise of enhancing the performance of electric vehicles and renewable energy storage solutions, making them more viable for a broader audience.

One of the key advantages of tabless battery manufacturing is its potential for cost-efficiency. By simplifying the production process, manufacturers can reduce the complexity associated with conventional battery designs. This streamlining not only lowers material costs but also shortens production times, enabling quicker ramp-up to meet growing market demand. Furthermore, the reduction in the number of components can translate to fewer quality control issues, which enhances overall reliability and performance. As a result, the adoption of these advanced manufacturing techniques can facilitate a more competitive landscape, driving both innovation and affordability in the energy sector.

The advancement of battery technology plays a crucial role in achieving sustainability goals, particularly with the introduction of the revolutionary 4680 tabless battery. These batteries are designed to enhance energy efficiency while minimizing waste, ultimately leading to a smaller carbon footprint for electric vehicles and renewable energy applications. By eliminating traditional tab connections, the 4680 batteries facilitate faster manufacturing processes and reduce the amount of raw materials needed, promoting a more sustainable production model.

Moreover, 4680 batteries not only optimize energy storage but also enhance the longevity and performance of electric vehicles, encouraging broader adoption of clean energy technologies. Their efficiency means that electric vehicles can travel longer distances on a single charge, decreasing reliance on fossil fuels and reducing greenhouse gas emissions. As manufacturers embrace these innovative battery solutions, the shift towards a greener future becomes increasingly attainable, resonating with both consumers and environmentally conscious businesses alike. This technology marks a significant step towards a more sustainable energy landscape, highlighting the industry’s commitment to reducing its ecological impact.

| Feature | Advantages | Sustainability Impact | Potential Applications |

|---|---|---|---|

| Tabless Design | Improved energy density and thermal performance | Reduced metal use and lower carbon footprint | Electric vehicles, consumer electronics |

| Faster Manufacturing | Lower production costs and time | Less energy consumption during manufacturing | Grid storage, renewable energy systems |

| Enhanced Safety | Reduced risk of battery failure and fire | Longer lifespan reduces waste | Aerospace, automotive industry |

| Higher Cycling Efficiency | Better performance over long-term usage | Minimizes resource extraction for replacements | Renewable energy solutions, portable devices |