Leave Your Message

In the pursuit of sustainable energy solutions, the emergence of sodium-ion battery technology represents a groundbreaking advancement in energy storage systems. Recent reports from the International Energy Agency (IEA) project a significant growth trajectory for the battery market, with estimates suggesting a market value that could exceed $100 billion by 2030. As the demand for cleaner, cost-effective alternatives to lithium-ion batteries rises, the development of Sodium-Ion Battery Manufacturing Pilot Lines becomes imperative. These pilot lines are essential for scaling production and optimizing manufacturing processes, enabling researchers and industries to address challenges such as raw material constraints and environmental concerns. By unlocking innovations in sodium-ion battery production, we are poised to enhance energy accessibility and efficiency, while also supporting global sustainability goals.

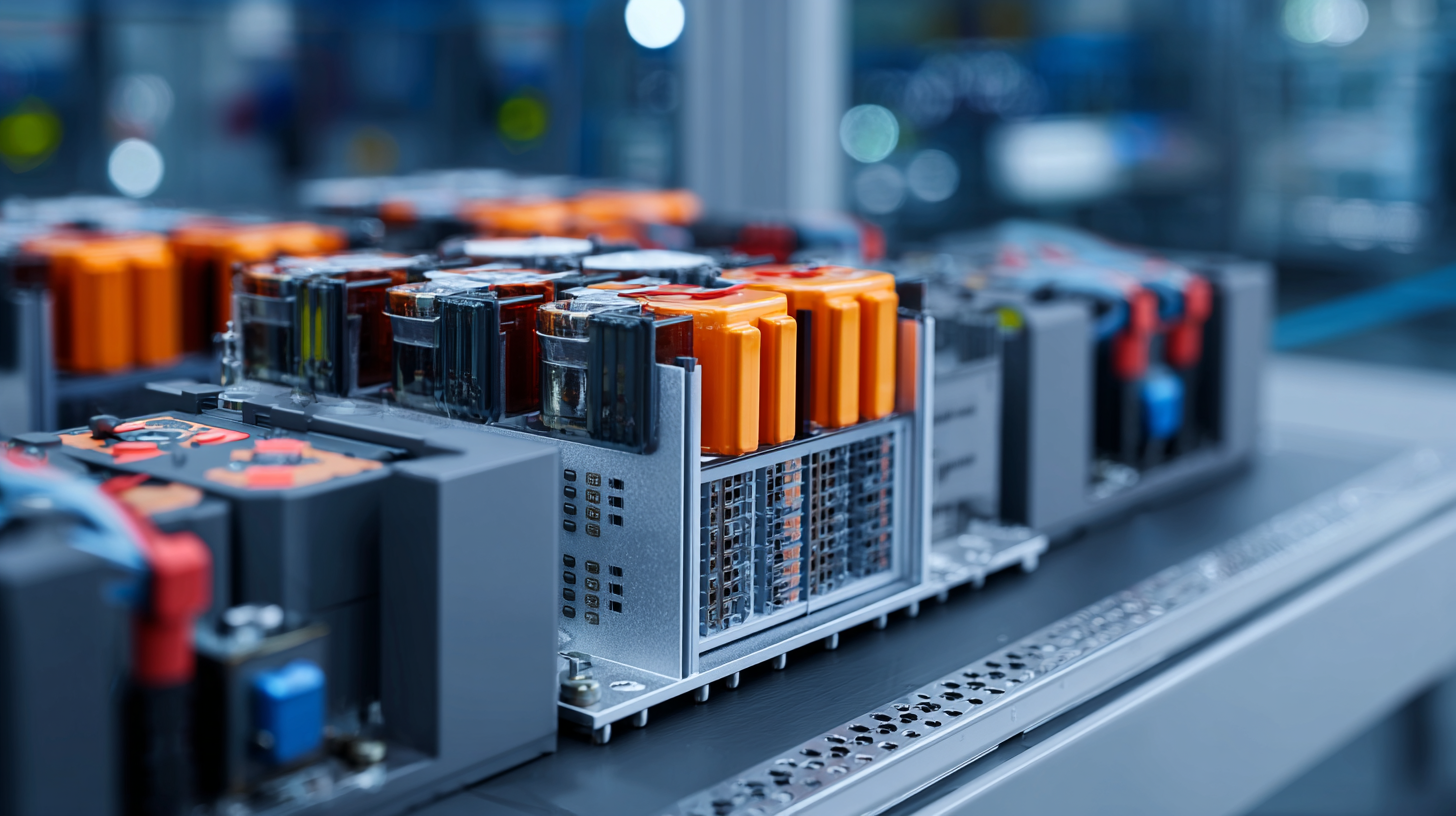

Sodium-ion batteries represent a significant advancement in energy storage technology, offering an alternative to traditional lithium-ion systems. The fundamental chemistry behind these batteries revolves around the movement of sodium ions, which play a pivotal role in the electrochemical processes that occur during charging and discharging. Unlike lithium, which is highly reactive and limited in supply, sodium is abundant and cost-effective, making it an attractive option for large-scale applications in renewable energy systems and electric vehicles.

The key to optimizing sodium-ion battery performance lies in understanding the interactions between the sodium ions and various cathode materials. Research has shown that utilizing materials such as sodium manganese oxide or sodium iron phosphate can enhance energy density and cycle stability. Furthermore, the development of novel anode materials—such as carbon-based compounds—facilitates efficient sodium storage and ion diffusion. This ongoing exploration into the fundamental chemistry not only addresses the current limitations of sodium-ion technology but also paves the way for scalable manufacturing processes that can meet future energy demands.

As the demand for efficient and sustainable energy storage solutions continues to rise, sodium-ion batteries are emerging as a promising alternative to traditional lithium-ion technology. One of the most significant advantages of sodium-ion batteries is their cost-effectiveness. According to a report by the International Energy Agency (IEA), the abundance of sodium, primarily derived from seawater, can reduce raw material costs by up to 50% compared to lithium. This economic benefit opens opportunities for wider market adoption, particularly in developing regions where resource accessibility is a critical factor.

Moreover, sodium-ion batteries offer enhanced performance in specific applications, especially in terms of safety and temperature tolerance. Unlike lithium-ion batteries, sodium-ion solutions have demonstrated a greater resistance to overheating and are less prone to fire hazards. A study conducted by the U.S. Department of Energy revealed that sodium-ion batteries maintain performance in extreme temperatures, making them suitable for grid storage and electric vehicle applications in diverse climates. Additionally, their lower environmental impact—arising from the non-toxic nature of sodium—positions them as a more sustainable choice in a world increasingly focused on green energy solutions.

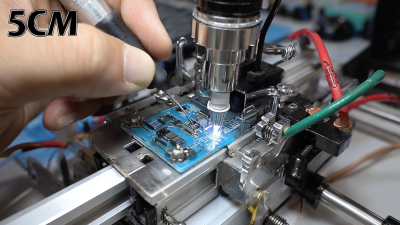

Innovative manufacturing techniques for sodium-ion batteries are rapidly developing, promising to revolutionize energy storage solutions for electric vehicles and other applications. Recent advancements in manufacturing pilot lines highlight the potential of sodium-ion technology to significantly reduce costs and enhance safety. For instance, reports indicate that sodium-ion batteries can offer approximately 30% lower costs compared to traditional lithium-ion batteries, making them an attractive alternative for mass-market vehicles. This affordability, combined with the abundance of sodium resources, positions sodium-ion technology as a cornerstone for sustainable energy practices, particularly in regions like India that are exploring safer and more economical energy solutions.

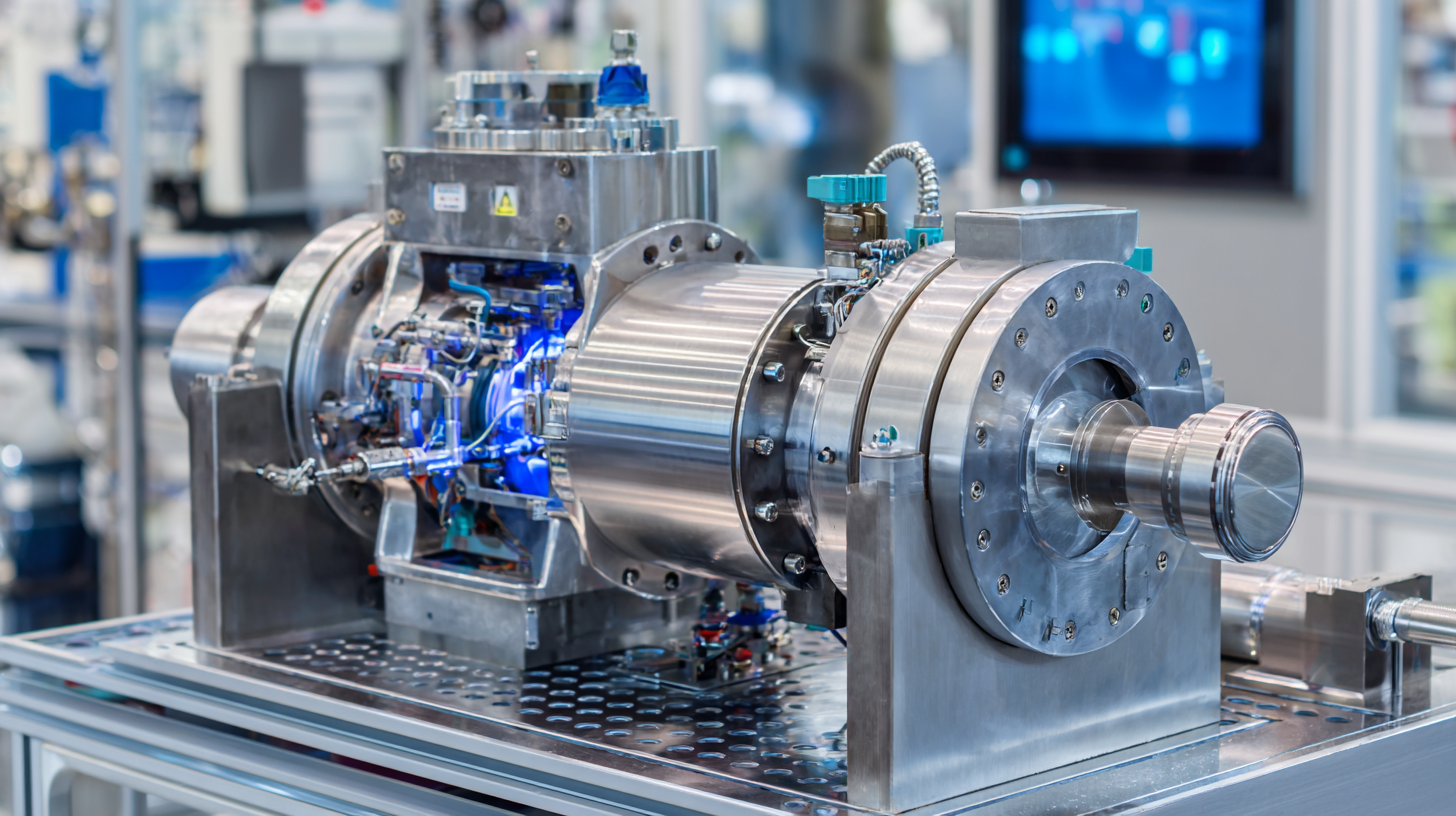

Manufacturers are taking bold steps forward in the sodium-ion battery market, with notable efforts from companies like Macsen Labs, which aims to establish a sodium-ion battery cell pilot line by 2026. This strategic move reflects a growing recognition of the importance of scalable and efficient production methods in meeting the increasing demand for clean energy technologies. Additionally, the development of solid-state innovations promises to enhance the performance of sodium-ion batteries, potentially yielding faster charging times and improved safety profiles essential for electric vehicles. As these innovative manufacturing techniques continue to evolve, they will play a crucial role in unlocking the future of energy storage and electric mobility.

| Innovation Technique | Description | Benefits | Pilot Line Stage | Expected Impact |

|---|---|---|---|---|

| Material Optimization | Improving active material formulations for enhanced performance. | Higher energy density and efficiency. | Development | Increase in overall battery capacity. |

| Advanced Coating Techniques | Utilizing new coating methods to improve electrode performance. | Enhanced conductivity and reduced degradation. | Scaling Up | Longer service life for batteries. |

| Automated Assembly | Implementation of robotic systems for battery assembly. | Increased production speed and consistency. | Production | Cost reduction in manufacturing processes. |

| Recycling Techniques | Innovative methods for recycling sodium-ion battery materials. | Reduction of waste and cost effectiveness. | Post-Production | Sustainable material recovery practices. |

| AI in Quality Control | Using artificial intelligence for monitoring production quality. | Early detection of defects and enhanced quality assurance. | Quality Assurance | Improved reliability of battery products. |

The rising interest in sodium-ion battery technology highlights its potential advantages over traditional lithium-ion batteries, particularly regarding environmental impacts. A recent analysis indicates that sodium-ion batteries can reduce mining-related ecological disruption by 40%, thanks to the abundance of sodium resources compared to lithium. Sodium is derived from widely available salt, significantly lowering extraction costs and energy consumption, making it a more sustainable choice for the future.

When assessing the environmental impacts of sodium-ion battery production, it's essential to consider carbon emissions. Industry reports suggest that sodium-ion battery production could emit up to 30% less CO2 compared to their lithium counterparts, mainly due to lower processing energy requirements. This shift not only supports a more circular economy but also aligns with global sustainability goals aimed at reducing greenhouse gas emissions in energy storage solutions.

Tip: If you are considering investing in energy solutions, prioritize technologies that demonstrate lower environmental footprints. Sodium-ion batteries not only present an innovative alternative but also contribute positively to ecological preservation. By choosing greener manufacturing options, consumers can play a crucial role in fostering a more sustainable future.

The market potential for sodium-ion battery technologies is gaining significant attention as industries seek sustainable alternatives to lithium-ion solutions. With the abundant availability of sodium, these batteries promise not only cost-effectiveness but also enhanced safety and environmental benefits. As global demand for energy storage solutions continues to rise, sodium-ion batteries are positioning themselves as a viable option for large-scale applications, including renewable energy integration and electric vehicles.

Recent advancements in manufacturing processes are paving the way for pilot lines dedicated to sodium-ion batteries. Innovations in electrode materials and electrolyte formulations are enhancing energy density and cycling stability, which are critical for commercial viability. As pilot production lines begin to emerge, we can expect rapid iterations of technology that will further refine performance metrics. This proactive approach in manufacturing will likely usher in an era where sodium-ion batteries can compete head-to-head with traditional lithium-ion batteries, ultimately reshaping the landscape of energy storage solutions.