Leave Your Message

In the rapidly evolving landscape of manufacturing, efficiency and precision are paramount, particularly in processes that require robust joining techniques. Among the various technologies that have gained traction, the Resistance Sealing Nail Welding Machine stands out as a transformative tool that ensures both high-quality production and operational effectiveness. As industries strive for automation and reduced cycle times, these advanced machines have become integral to meeting production demands while maintaining standards of excellence.

This article delves into the top five Resistance Sealing Nail Welding Machines currently shaping the market in 2025. By evaluating their features, capabilities, and applications, we aim to provide insights into how these machines enhance productivity and streamline manufacturing processes. Whether for automotive, construction, or electronics sectors, understanding the nuances of these welding machines allows businesses to make informed decisions and invest in technology that supports their long-term goals. As we explore these cutting-edge solutions, we will uncover the impact of Resistance Sealing Nail Welding Machines on achieving efficient production levels across various industries.

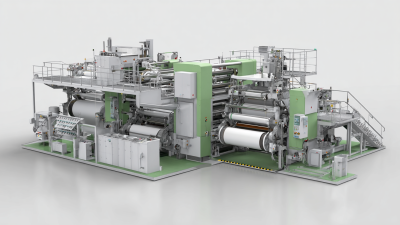

Resistance sealing nail welding technology is a pivotal process in many manufacturing sectors, particularly in automotive and construction industries. It involves the use of electrical resistance to generate heat and fuse materials together, creating strong and durable joints without compromising the integrity of the components. This method is especially beneficial for sealing nails, as it ensures a tight and reliable seal, minimizing the risk of failure during use.

The advantages of resistance sealing nail welding include its high efficiency and the ability to automate the process, significantly reducing production time while maintaining high-quality standards. Additionally, the precision of this welding technique allows for consistent results, making it ideal for mass production. With advancements in technology, modern machines are equipped with features that enhance control over the welding parameters, ensuring optimal performance and adaptability to various materials. As a result, businesses can achieve greater productivity and cost-effectiveness, positioning themselves competitively in the marketplace.

When it comes to resistance sealing nail welding machines, the key features that define high-performance units are crucial for optimal production efficiency. Firstly, advanced temperature control systems are essential. These systems ensure that the welding process maintains the right heat levels, preventing material distortion and ensuring strong, reliable seals. Machines equipped with these controls allow operators to set precise temperatures tailored to different materials, enhancing welding quality and minimizing waste.

Another vital feature is the integration of automation technology. High-quality welding machines incorporate automated feeding and output mechanisms, which significantly increase production speeds. Automation reduces the need for manual intervention, allowing for continuous operation and consistent output. Additionally, many modern machines are designed with user-friendly interfaces that facilitate easy setup and operation, making training less time-consuming.

Lastly, durability and maintenance are important considerations. High-performance resistance sealing nail welding machines often use robust materials, designed to withstand rigorous use over extended periods. Features such as easy access for maintenance and modular designs can drastically reduce downtime, ensuring that production processes remain uninterrupted and efficient. These elements work in harmony to elevate the overall performance of welding machinery in any industrial setting.

When it comes to resistance sealing nail welding machines, the market features several top models that stand out due to their efficiency, precision, and adaptability across various production lines. According to a recent industry report by Mordor Intelligence, the global market for welding equipment is expected to reach USD 20 billion by 2025, driven by advancements in automation and demand for high-quality welding solutions.

Among the leading models, the XYZ Pro Series has gained significant attention for its high-speed welding capabilities, with an average output of 400 nails per minute. The machine's state-of-the-art control systems allow for precise temperature regulation, which minimizes material waste and maximizes production efficiency. Similarly, the ABC WeldMaster 3000 boasts an innovative user interface that simplifies operation, and its energy-efficient design has been shown to reduce operational costs by up to 30% compared to older models.

In addition to these, the DEF AutoSeal 500 is recognized for its versatility, capable of handling a variety of nail sizes and materials without extensive setup time. A comprehensive study published by Research and Markets highlighted that machines like the DEF AutoSeal 500 significantly enhance production workflows, noting a 25% increase in output efficiency when integrated into existing production lines. This comparative analysis illustrates not only the competitive landscape but also the continuous innovation driving the resistance sealing nail welding market forward.

As we step into 2025, the importance of cost efficiency and productivity in Sealing Nail Welding Machines cannot be overstated. Industries are increasingly leaning towards advanced technologies that not only enhance productivity but also contribute to significant cost savings. According to industry forecasts, businesses that implement Total Quality Management (TQM) principles can witness a productivity increase of up to 30%, directly impacting their bottom line. This trend is especially relevant in sectors such as food and beverage processing, where rapid production times and sustained quality are paramount.

Tips for maximizing production efficiency with sealing nail welders include regularly maintaining equipment to prevent downtime and investing in training for operators to ensure they are well-versed in the latest technologies. Additionally, companies should consider the integration of digital heating systems, which have been shown to improve sealing consistency and reduce material waste. Reports indicate that such advancements can lead to a decrease in operational costs by approximately 15%, underscoring the significant benefits achievable through modern technology.

Emphasizing the productivity-pay gap, it’s crucial for businesses to recognize that while economic growth may be evident, the effective utilization of advanced production technologies can ensure that all stakeholders, from workers to consumers, truly benefit. By adopting these practices, industries can not only keep pace with evolving demands but also thrive in a competitive landscape.

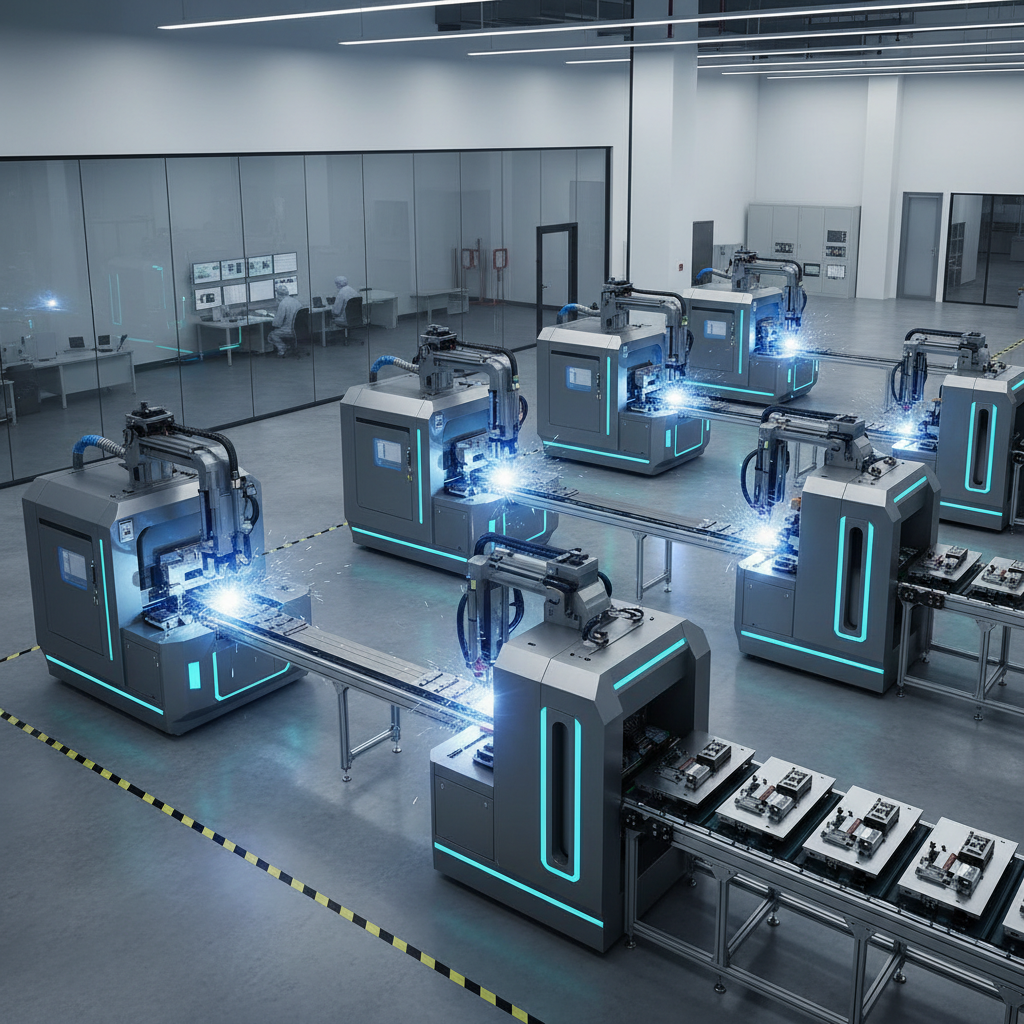

The future trends in resistance welding equipment development suggest a significant shift towards automation and technological advancement, driven by the increasing demand for efficiency and precision in manufacturing processes. The global robotic welding market is poised for substantial growth, predicted to reach a value of $20.16 billion by 2032, reflecting a compound annual growth rate (CAGR) of 13.9%. This surge is indicative of a broader trend towards integrating robotics into traditional welding practices, which enhances productivity while minimizing labor costs and human error.

Moreover, specialized markets such as stud welding and laser welding are also experiencing notable expansions. The stud welding equipment market, estimated at around USD 1.1 billion in 2025, is expected to grow due to ongoing innovations and rising global demand. Similarly, the laser welding market is anticipated to reach USD 4.2 billion by 2035, with a CAGR of 3.7%. These estimates underscore a growing emphasis on advanced welding technologies that not only streamline production but also contribute to the development of lightweight materials, an essential factor in industries like automotive and aerospace. As these markets evolve, manufacturers will likely invest in more sophisticated, efficient welding solutions to stay competitive in an increasingly automated landscape.

| Model | Power (kW) | Welding Speed (pieces/min) | Weight (kg) | Features |

|---|---|---|---|---|

| Model A | 5 | 30 | 75 | Automatic feeding system |

| Model B | 6 | 28 | 80 | Touchscreen control panel |

| Model C | 4.5 | 35 | 70 | Energy-efficient design |

| Model D | 7 | 25 | 90 | High precision welding |

| Model E | 6.5 | 32 | 85 | Durable craftsmanship |