Leave Your Message

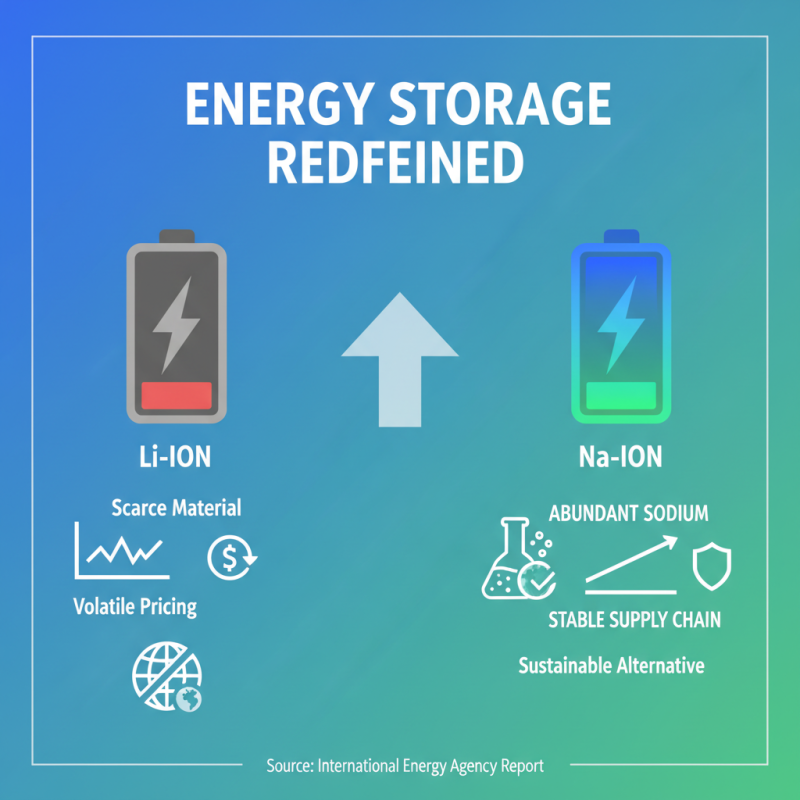

The landscape of energy storage is rapidly evolving, with Sodium-Ion Battery Manufacturing Pilot Lines emerging as a focal point for innovation and development. As the demand for sustainable and cost-effective energy solutions escalates, sodium-ion technology has garnered increased attention due to its potential to offer a more abundant and environmentally friendly alternative to lithium-ion batteries. According to a report by the International Energy Agency, the market for energy storage is expected to reach a staggering 1,000 GWh by 2030, making the exploration of new battery technologies more critical than ever.

In 2025, it is anticipated that the capabilities of Sodium-Ion Battery Manufacturing Pilot Lines will play a pivotal role in enabling large-scale production and commercialization. Insights from various industry studies suggest that advancements in manufacturing processes, material efficiency, and battery performance are on the horizon. Reports indicate that pilot lines are expected to enhance operational scalability, reduce production costs substantially, and improve the overall viability of sodium-ion batteries in various applications, including electric vehicles and grid storage.

As the industry moves forward, the refinement of Sodium-Ion Battery Manufacturing Pilot Lines will be instrumental in addressing the challenges that have historically hindered the widespread adoption of sodium-ion technology. By leveraging innovative manufacturing practices, stakeholders can accelerate the transition towards more sustainable battery solutions, propelling the energy storage sector into a new era defined by resilience and sustainability.

The emergence of sodium-ion battery technology is poised to revolutionize energy storage solutions, offering a compelling alternative to traditional lithium-ion batteries. According to a report by IDTechEx, the global sodium-ion battery market is projected to grow significantly, with estimates indicating a compound annual growth rate (CAGR) of over 50% between 2023 and 2028. This rapid adoption is driven by the abundant availability of sodium compared to lithium, which not only reduces costs but also aligns with sustainability goals as sodium sources are widely distributed.

As we approach 2025, advancements in manufacturing pilot lines for sodium-ion batteries indicate major trends in scalability and efficiency. A study by the International Energy Agency suggests that by utilizing optimized manufacturing processes, the production costs of sodium-ion batteries could decrease by up to 30% by 2025. This will enhance their viability for large-scale applications, particularly in renewable energy integration and electric vehicles. Furthermore, the development of efficient sodium-ion battery chemistries promises higher energy densities that can rival existing technologies, making them suitable for a wider range of applications in energy storage infrastructure.

The strategic push for sodium-ion technology is also reflected in rising investments. Research from BloombergNEF shows that leading battery manufacturers are allocating funds towards sodium-ion technology development, with investments reaching billions of dollars over the next few years. This not only solidifies the technology's role in balancing energy supply and demand but also strengthens its potential in addressing the global push for cleaner, more sustainable energy systems.

| Dimension | 2023 | 2024 | 2025 |

|---|---|---|---|

| Global Market Size (in Billion USD) | 1.5 | 2.5 | 4.0 |

| Estimated Annual Production Capacity (in MWh) | 500 | 1500 | 3000 |

| Average Energy Density (Wh/kg) | 120 | 140 | 160 |

| Market Share Compared to Lithium-Ion (%) | 5 | 10 | 15 |

| Key Application Sectors | Transport, Grid | Transport, Grid, Industrial | Transport, Grid, Industrial, Residential |

Sodium ion batteries (SIBs) are emerging as a promising alternative to traditional lithium ion batteries (LIBs), offering significant advantages that may redefine energy storage solutions in the coming years. One of the most notable benefits of SIBs is their sustainability. Sodium, being abundant and widely available, can reduce the dependency on lithium, which is not only scarce but also subject to volatile pricing. According to a recent report by the International Energy Agency, the availability of sodium could lead to a more stable supply chain for energy storage solutions, which is critical as the industry ramps up production to meet increasing energy demands.

Furthermore, sodium ion batteries exhibit excellent performance characteristics at lower costs. Research indicates that SIBs can achieve comparable energy densities to lithium batteries while offering lower manufacturing costs. A study published in the Journal of Power Sources noted that SIBs could be produced at a cost that is approximately 30% lower than LIBs, making them a more economically viable choice for large-scale applications. This cost-effectiveness, combined with their ability to operate efficiently at higher temperatures, positions sodium ion batteries as ideal candidates for various applications, from electric vehicles to energy storage systems for renewable sources. As industries and economies seek greener and more sustainable energy solutions, the advantages of sodium ion over lithium ion batteries will likely drive accelerated adoption and innovation in battery technology.

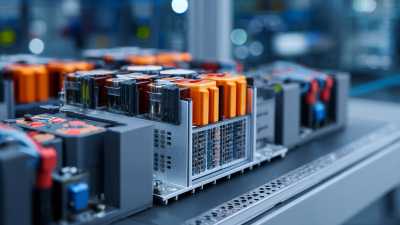

The current manufacturing processes for sodium ion batteries are advancing rapidly as the demand for efficient energy storage systems grows. One of the key trends in the manufacturing of these batteries is the shift towards scalable production techniques that can accommodate diverse applications, ranging from grid storage to electric vehicles. The use of abundant raw materials, such as sodium sourced from seawater, sets sodium ion batteries apart from their lithium counterparts, offering a more sustainable approach to energy storage.

In terms of manufacturing, innovative methods are being explored to optimize the anode and cathode materials, with a focus on enhancing energy density and cycle life. Techniques such as sol-gel synthesis and spray drying are gaining traction as they allow for better control over particle size and morphology, ultimately leading to improved battery performance. Additionally, the integration of automated processes is becoming more prevalent, allowing for consistent quality and efficiency as production scales up. These advancements suggest a bright future for sodium ion batteries in the energy market, where robust manufacturing processes will play a crucial role in meeting global energy needs by 2025.

This chart illustrates the projected increase in sodium ion battery manufacturing capacity from 2023 to 2025, showcasing a significant growth trend as the industry moves towards more sustainable energy storage solutions.

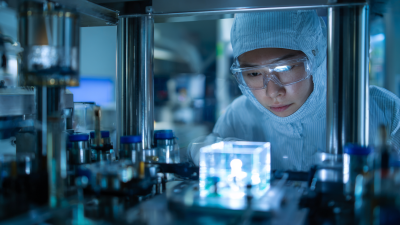

The production of sodium-ion batteries is gaining momentum as manufacturers explore innovative techniques to overcome existing challenges. A significant obstacle remains in the scalability and efficiency of the manufacturing processes. As production ramps up, companies must focus on streamlining operations while maintaining high-quality standards. This involves integrating advanced automation technologies and AI-driven monitoring systems that improve consistency and reduce costs. Innovations in material science also play a crucial role, where the development of new cathodes and electrolytes can enhance battery performance and safety.

Tips: When considering sodium-ion battery production, manufacturers should invest in research collaborations with academic institutions to stay at the forefront of technological advancements. Additionally, it’s vital to conduct thorough market analysis to anticipate demand shifts and adapt production accordingly.

Another challenge is the environmental impact of raw material extraction and processing. To address this, the industry is focusing on sustainable sourcing practices and the development of recycling methods for battery components. Innovations such as closed-loop recycling not only reduce waste but also lower the carbon footprint associated with new battery production. As the sector matures, more players are expected to implement eco-friendly practices, which will enhance the overall sustainability of sodium-ion batteries.

Tips: Engaging with suppliers who prioritize sustainability can improve long-term viability and foster positive public perception. Additionally, exploring circular economy models can lead to new revenue streams while promoting environmental responsibility.

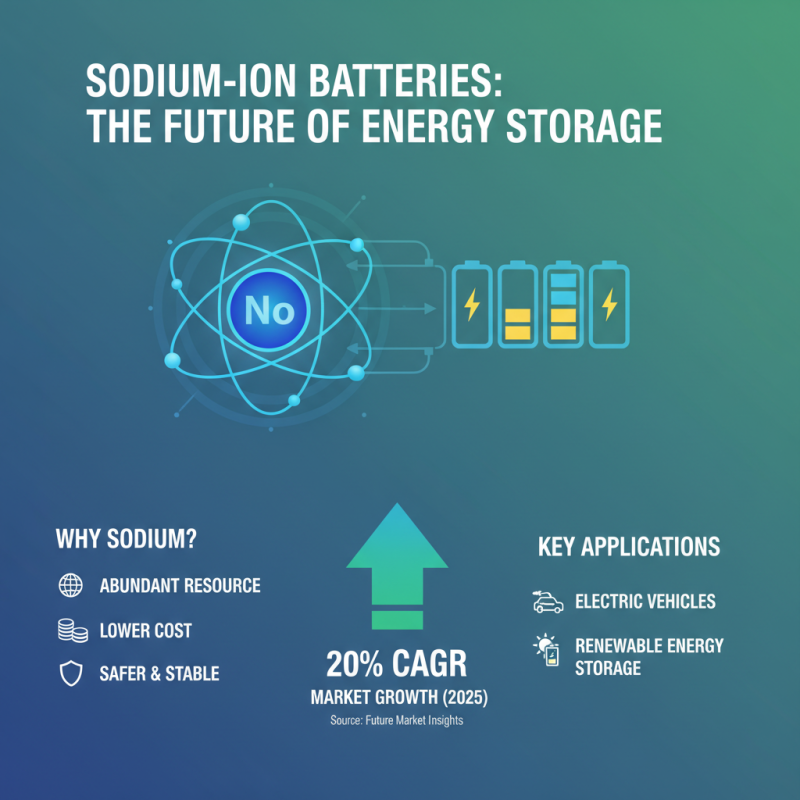

As the battery market continues to evolve, sodium-ion batteries (SIBs) are gaining significant attention as a promising alternative to lithium-ion technologies. According to a recent report from Future Market Insights, the sodium-ion battery market is expected to grow at a compound annual growth rate (CAGR) of approximately 20% through 2025. This growth is driven by increasing demand for energy storage solutions in electric vehicles and renewable energy applications, where the abundance and cost-effectiveness of sodium can provide a distinct advantage over traditional lithium-based systems.

Industry experts suggest that by 2025, advancements in manufacturing processes will enhance the efficiency and performance of sodium-ion batteries, making them a more viable option for large-scale energy storage. Recent analyses indicate that improvements in cathode materials and the optimization of electrolyte formulations could potentially increase the overall energy density of SIBs, putting them in direct competition with lithium technologies. This shift is further supported by a growing ecosystem of players investing in SIB development, indicating a robust future for this technology.

Tip: For companies looking to enter the sodium-ion battery market, it's crucial to stay updated with ongoing research and development initiatives. Collaborating with academic institutions and exploring innovative materials could lead to breakthroughs that significantly enhance battery performance and market viability. Engaging in pilot projects and industry partnerships will also facilitate knowledge transfer and accelerate the commercialization of sodium-ion batteries.