Leave Your Message

In recent years, the demand for sustainable and efficient energy storage solutions has surged, leading to increased interest in sodium-ion batteries as a viable alternative to traditional lithium-ion technology. The initiation of a Sodium-Ion Battery Manufacturing Pilot Line represents a significant step towards commercializing this innovative technology. This pilot line not only serves as a crucial testing ground for production processes but also helps in understanding the scalability of sodium-ion battery manufacturing. As companies aim to transition to cleaner energy solutions, mastering the complexities of setting up a pilot line is essential. This guide will explore the key strategies and considerations for successfully launching a Sodium-Ion Battery Manufacturing Pilot Line, including selecting appropriate materials, establishing efficient production techniques, and addressing potential challenges in the manufacturing process. By following these insights, stakeholders can better prepare for the future of energy storage and capitalize on the growing market for sodium-ion batteries.

When considering the establishment of a sodium ion battery manufacturing pilot line, selecting the right location is paramount for success. One of the key strategies involves assessing proximity to supply chain resources, including raw materials and component suppliers. An ideal location minimizes transportation costs and ensures a steady flow of necessary inputs, which can significantly enhance production efficiency.

Additionally, being close to research institutions or technology hubs fosters collaboration, enabling access to cutting-edge innovations and skilled workforce.

Another critical factor is evaluating regional regulations and incentives. Understanding local policies related to energy production, environmental compliance, and manufacturing can influence the decision-making process. Regions that offer supportive frameworks for clean energy initiatives often provide financial incentives, tax breaks, or grants, which can reduce operational costs.

Furthermore, analyzing the area's infrastructure, including transportation networks and utilities, ensures that the location can support the operational demands of a battery pilot line while facilitating logistics and distribution. This combination of resource availability, regulatory environment, and infrastructure readiness is essential for launching a successful sodium ion battery manufacturing pilot.

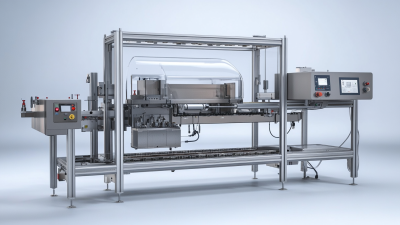

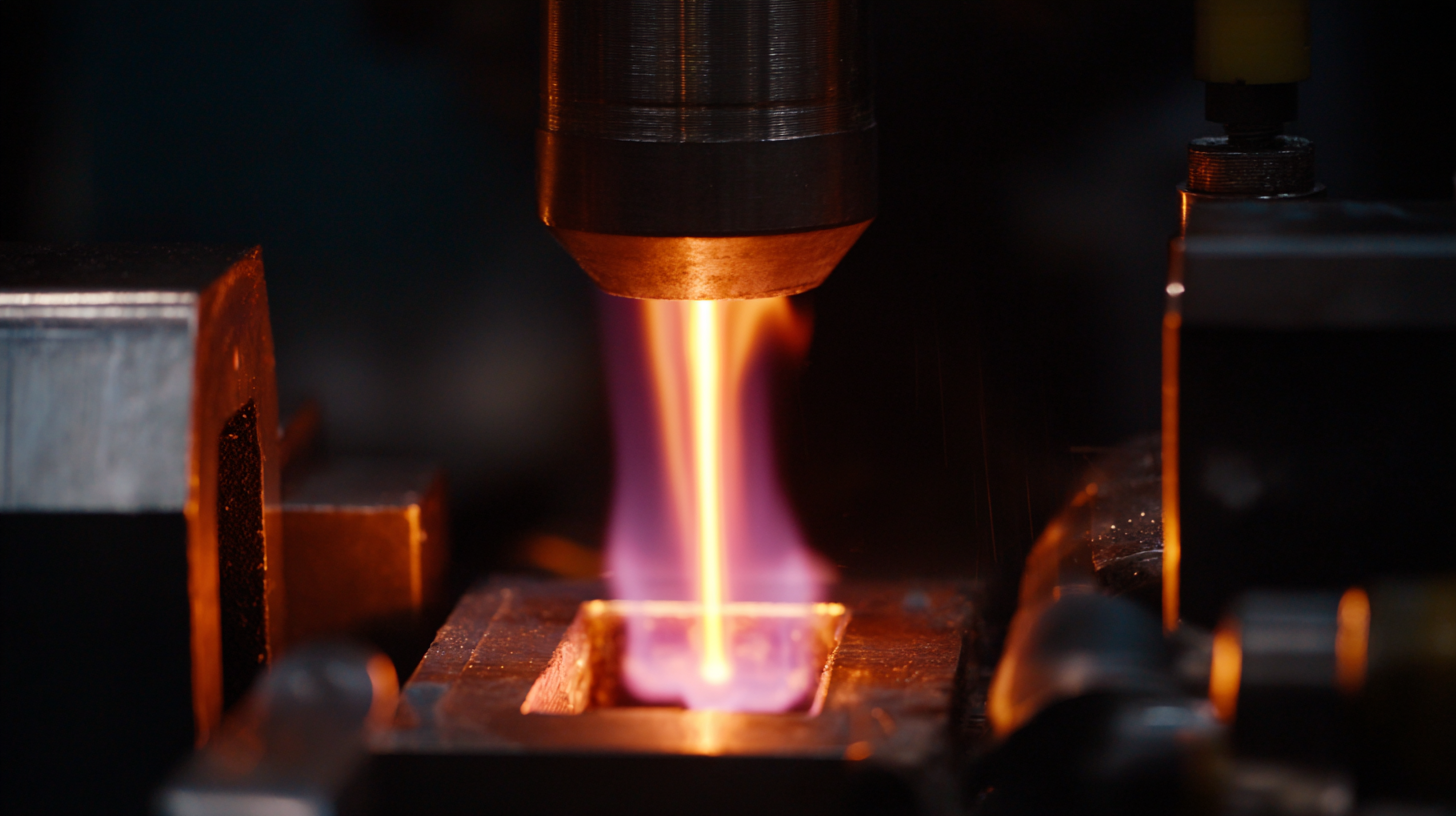

The production of sodium-ion batteries (SIBs) is gaining momentum as a cost-effective alternative to lithium-ion batteries. Key technologies crucial for launching a pilot line in sodium-ion battery manufacturing include advanced battery chemistry, efficient electrode materials, and scalable production techniques. An emphasis on developing high-performance anodes and cathodes, using materials such as carbon and sodium transition metal oxides, is vital for enhancing energy density and cycle life. Furthermore, improving the coating and assembly processes can help streamline manufacturing operations, minimizing defects and maximizing output.

In addition to innovative materials, the deployment of automation and digital technologies plays a significant role in the production efficiency of sodium-ion batteries. Integrating AI and digital twin technologies can optimize manufacturing processes, ensuring real-time monitoring and adaptive management of production lines. As the industry explores new avenues for scaling up production, collaboration across the supply chain will be essential to address challenges and leverage emerging opportunities, positioning sodium-ion batteries as a competitive player in the energy storage market.

This bar chart illustrates the projected production capacity of a sodium ion battery manufacturing pilot line over four quarters, highlighting the increasing capacity from 50 MWh in Q1 to 120 MWh in Q4.

Establishing quality control measures in sodium ion battery manufacturing is pivotal for achieving consistency and reliability in production. According to a report published by the International Energy Agency (IEA), the global demand for energy storage is projected to reach 2,850 GWh by 2030, emphasizing the urgent need for high-quality battery technologies. Implementing rigorous quality control protocols at the pilot line phase not only ensures product safety but also contributes to building customer trust and market credibility.

Quality control can be divided into several critical stages, starting with raw material evaluation and ending with final product testing. A study from Wood Mackenzie indicates that up to 30% of battery performance issues can be traced back to subpar raw materials. Monitoring the inputs throughout the manufacturing process is essential; for instance, using advanced spectrometric methods to assess the purity of materials can prevent costly defects. Furthermore, establishing automated testing stations for performance metrics, such as capacity and cycle life, can facilitate immediate feedback and quicker adjustments, enhancing overall efficiency and product quality. As recognized by the Battery Safety Initiative, adhering to stringent quality standards can significantly reduce the likelihood of failures, with potential risks diminishing by over 50% when comprehensive testing is integrated into the manufacturing cycle.

Launching a sodium ion battery manufacturing pilot line requires not only advanced technology but also a well-prepared workforce. Effective workforce recruitment and training are crucial steps that determine the success of this endeavor. Companies should focus on creating a comprehensive recruitment strategy that highlights the unique benefits of sodium ion technology, thereby attracting skilled professionals who are passionate about innovation in sustainable energy solutions.

Tips: When recruiting, consider utilizing platforms that specialize in clean energy jobs to reach a targeted audience. Leverage social media to share success stories and insights about your projects to attract talent interested in being part of a groundbreaking industry.

Training is equally important. Implementing a robust onboarding program that includes hands-on experience with battery manufacturing processes can help new employees feel valued and prepared. Ongoing training sessions that cover the latest advancements in sodium ion technology will not only enhance their skills but also foster a culture of continuous learning within the organization.

Tips: Create interactive workshops and mentorship programs that encourage knowledge sharing among employees. Regularly update training materials to reflect current industry trends and technologies, ensuring your workforce remains competitive and knowledgeable.

The successful scaling up of sodium ion battery manufacturing post-pilot line evaluation requires meticulous planning and adherence to best practices. Recent reports indicate that the global sodium ion battery market is expected to reach USD 1.2 billion by 2027, driven by the increasing demand for energy storage solutions. To capitalize on this burgeoning market, manufacturers should focus on optimizing production processes and establishing robust quality control measures.

Tips: Ensure that all equipment is calibrated correctly before scaling up production. This reduces variability and enhances product reliability. Furthermore, invest in staff training to optimize efficiency and minimize human error during the transition from pilot to mass production.

In addition, leveraging insights from chaos engineering practices can aid in identifying potential bottlenecks in manufacturing processes. By systematically testing failures and learning from these challenges, manufacturers can refine their operations. A recent survey noted that companies implementing chaos engineering saw a 30% improvement in system resilience, a crucial factor in maintaining production uptime as operations scale.

Tips: Implement continuous feedback loops throughout the pilot line evaluation to capture real-time data on performance metrics. This approach enables prompt adjustments and fosters a culture of innovation within the production team.