Leave Your Message

In the rapidly evolving landscape of energy storage, the need for innovation is more pressing than ever, especially in the realm of Battery Sleeve Labeling. As we strive to meet the demands of cleaner and more efficient energy solutions, the significance of effective labeling cannot be overstated. Battery Sleeve Labeling not only enhances safety by clearly identifying the specifications and usage instructions of different battery types but also serves as a critical component in inventory management and recycling processes. This blog aims to explore the transformative potential of Battery Sleeve Labeling innovations through a tutorial that delves into the latest technologies and best practices. By revolutionizing how we approach battery labeling, we can improve operational efficiencies, support sustainability efforts, and pave the way for a more intelligent energy storage future.

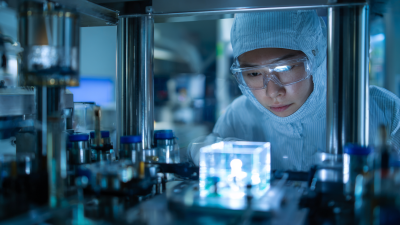

The rapid advancement of battery technology necessitates innovative approaches to battery sleeve labeling, which play a crucial role in enhancing efficiency and usability. Emerging trends in this field showcase a shift toward smart labeling systems that can provide real-time data about battery status, charge levels, and maintenance needs. By integrating IoT technology, these labels can facilitate seamless communication with devices, allowing users to monitor and manage their energy storage systems more effectively. This evolution not only improves user experience but also supports greater safety measures, reducing risks of misuse or accidents.

Another exciting development is the use of eco-friendly materials in battery sleeve labeling. As sustainability becomes a key focus in energy storage solutions, manufacturers are exploring biodegradable and recyclable materials that minimize environmental impact. These innovations not only meet regulatory demands but also resonate with eco-conscious consumers. Additionally, advanced printing techniques are enabling more durable and visually appealing labels that can withstand various environmental conditions, ensuring legibility and functionality over a battery's lifespan. Such trends are paving the way for a future where battery sleeve labeling is both practical and aligned with sustainability objectives, thus driving the energy storage industry forward.

The rapid evolution in energy storage solutions has sparked a renewed focus on the materials used in battery sleeve labeling. As industries strive for sustainability, innovative materials are stepping into the spotlight. According to a report by MarketsandMarkets, the global sustainable packaging market is projected to reach $474 billion by 2026, indicating a significant shift towards eco-friendly solutions across various sectors. In this context, battery sleeve labeling is not just a functional accessory but also an opportunity for manufacturers to embrace sustainable practices.

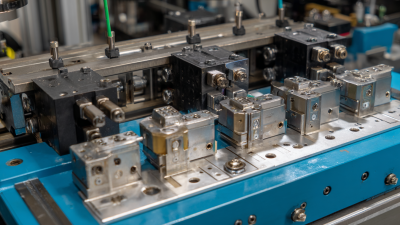

Employing biodegradable polymers and recycled materials in battery sleeve labels can reduce the environmental impact of battery production. A study by the International Energy Agency (IEA) highlighted that the battery market is expected to grow exponentially, with electric vehicle (EV) sales forecasted to reach 30 million units by 2025. This surge necessitates innovative labeling solutions that not only comply with sustainability standards but also enhance the battery's performance and lifecycle. By leveraging advancements in material science, companies can create labels that withstand harsh conditions while being readily recyclable, thereby supporting the circular economy.

As the industry looks towards the future, the integration of sustainable materials in battery sleeve labeling will play a critical role in aligning with global sustainability goals. Transitioning to these innovative materials is not merely an option but a crucial step towards minimizing the ecological footprint of energy storage solutions.

In the rapidly evolving world of energy storage, the significance of modern battery sleeve labeling cannot be overstated. Smart technologies are transforming traditional labeling methods into dynamic information systems that provide vital data at a glance. These advanced labels not only identify battery specifications but also communicate real-time performance metrics, such as charge levels and health status. By leveraging QR codes and NFC technology, users can quickly access a wealth of information, enhancing both safety and efficiency in battery management.

Moreover, the integration of smart features in battery sleeve labels supports predictive maintenance and operational efficiency. Manufacturers can embed sensors that monitor environmental conditions, alerting users to potential issues before they escalate. This proactive approach reduces downtime and extends battery life, fostering a more sustainable energy storage solution. As these innovations continue to emerge, they will play a crucial role in shaping the future of energy storage, making smart labeling an essential element of battery technology. The synergy between smart technologies and battery sleeve labels not only optimizes performance but also empowers users with knowledge, leading to smarter energy consumption.

The transformative landscape of energy storage is increasingly being shaped by regulatory standards that govern battery sleeve labeling. According to a recent report from the International Energy Agency (IEA), the global energy storage market is projected to expand to over 1,800 GWh by 2030. This surge puts pressure on manufacturers to comply with stringent labeling requirements that ensure safety, recyclability, and sustainability. Regulatory standards are not just about compliance; they play a crucial role in fostering consumer trust, driving forward the adoption of energy storage solutions.

Moreover, initiatives from organizations such as the Battery Safety Working Group are setting benchmarks for labeling practices that enhance safety measures. For instance, it is estimated that nearly 70% of battery-related incidents stem from improper handling, underscoring the need for precise labeling that includes hazard warnings and recycling instructions. With innovations in digital and smart labeling technology on the horizon, manufacturers are positioned to not only meet regulatory demands but also to provide consumers with interactive labels that convey essential product information, contributing to greater awareness and safety in energy storage applications.

| Labeling Standard | Description | Impact on Battery Industry | Future Trends |

|---|---|---|---|

| IEC 62619 | International standard for safety requirements in battery systems | Ensures consumer safety and boosts confidence in battery products | Increasing adoption of smart labeling technologies |

| UN 38.3 | Test requirements for transport of lithium batteries | Minimizes risks during shipping and handling | More rigorous compliance tracking systems |

| ISO 9001 | Quality management standards applicable to battery manufacturers | Improves product quality and reduces defects | Integration of sustainability metrics into quality frameworks |

| RoHS Directive | Regulation limiting the use of specific hazardous materials in electronics | Drives innovation for safer battery materials | Emerging interest in biodegradable alternatives |

The future of battery sleeve labeling innovations is set to play a crucial role in shaping energy storage solutions. As the demand for efficient energy storage systems increases, particularly in the context of electric vehicles, new labeling technologies can enhance the usability and management of batteries. Improved labeling will provide essential information about battery specifications, recycling instructions, and performance metrics, enabling users and companies alike to optimize battery life and sustainability.

As advancements in lithium-ion batteries continue to progress, the integration of smart labeling within battery sleeves stands out as a promising area of innovation. This technology not only facilitates better tracking and monitoring but also aligns with the growing emphasis on a circular economy by supporting the effective urban mining of end-of-life batteries. By embracing these labeling innovations, stakeholders can better address challenges related to battery disposal and recycling, ultimately contributing to more sustainable energy systems and reducing the environmental footprint of energy storage solutions.