Leave Your Message

The manufacturing industry is undergoing a transformative shift, propelled by advancements in technology that enhance efficiency and precision. Among these innovations, the Integrated Calendering and Slitting Machine stands out as a pivotal tool that can dramatically improve production processes. According to a recent report by MarketsandMarkets, the global market for advanced manufacturing technologies is projected to reach $507 billion by 2025, reflecting a compound annual growth rate (CAGR) of 11.5%. This growth is driven by a demand for increased operational efficiency and reduced production costs, which integrated technologies can deliver. By incorporating state-of-the-art features, the Integrated Calendering and Slitting Machine not only optimizes workflow but also ensures superior product quality, making it an essential investment for manufacturers aiming to stay competitive in a rapidly evolving market. As businesses embrace digital transformation, understanding the capabilities and advantages of this technology will be crucial for achieving operational excellence.

The manufacturing industry is undergoing a transformative shift, propelled by advancements in technology that enhance efficiency and precision. Among these innovations, the Integrated Calendering and Slitting Machine stands out as a pivotal tool that can dramatically improve production processes. According to a recent report by MarketsandMarkets, the global market for advanced manufacturing technologies is projected to reach $507 billion by 2025, reflecting a compound annual growth rate (CAGR) of 11.5%. This growth is driven by a demand for increased operational efficiency and reduced production costs, which integrated technologies can deliver. By incorporating state-of-the-art features, the Integrated Calendering and Slitting Machine not only optimizes workflow but also ensures superior product quality, making it an essential investment for manufacturers aiming to stay competitive in a rapidly evolving market. As businesses embrace digital transformation, understanding the capabilities and advantages of this technology will be crucial for achieving operational excellence.

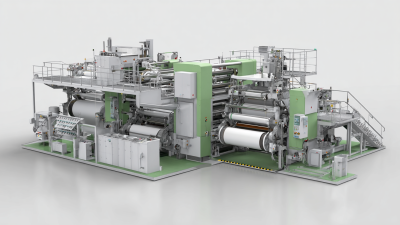

Integrated calendering and slitting machine technology represents a significant advancement in the manufacturing process, particularly in industries that require precise material manipulation. These machines combine two crucial operations: calendering, which involves compressing materials to achieve specific thickness and smoothness, and slitting, which allows for cutting materials into desired widths. According to industry reports, the efficiency of integrated machines can reduce production time by up to 30%, enabling manufacturers to respond more rapidly to market demands.

When selecting an integrated calendering and slitting machine, it is essential to consider key factors such as energy consumption and throughput rates. Advanced models now feature smart technology that optimizes energy use, significantly lowering operational costs. In fact, studies have shown that machines equipped with energy-efficient technology can decrease power consumption by approximately 15-20%.

**Tips:** When evaluating different machines, always look for those that offer automation features, as they can enhance accuracy and reduce labor costs. Additionally, ensure that the system you choose supports easy integration with existing project management tools for streamlined operations. Staying informed about technological advancements will also give you a competitive edge in adapting your processes to meet evolving industry standards.

| Feature | Description | Benefits | Application |

|---|---|---|---|

| Integrated Design | Combines calendering and slitting processes into a single machine. | Reduced footprint and improved workflow efficiency. | Manufacturing of flexible materials such as plastic films and textiles. |

| High Precision | Utilizes advanced sensors and control systems for accurate thickness and width control. | Consistent product quality and reduced waste. | Automotive, electronics, and packaging industries. |

| Versatile Processing | Capable of handling various material types and thicknesses. | Flexibility to adapt to different production needs. | Textiles, packaging films, and composite materials. |

| Automated Controls | Features PLC and HMI for easy operation and monitoring. | Increased operational efficiency and reduced labor costs. | Used in various production lines across multiple industries. |

| Energy Efficient | Engineered for lower energy consumption without sacrificing performance. | Cost savings in utility bills and environmentally friendly operation. | Applicable in high-volume manufacturing settings. |

Upgrading to advanced manufacturing technology, particularly through the adoption of the latest integrated calendering and slitting machines, offers manufacturers significant benefits that can enhance efficiency and product quality. One of the primary advantages is improved precision in the production process. These advanced machines utilize sophisticated automation and control systems that minimize human error, resulting in consistent and high-quality outputs. This precision not only meets rigorous industry standards but also optimizes material utilization, reducing waste and production costs.

Another critical benefit is the increased operational speed and productivity. Modern integrated machines are designed to handle larger volumes with greater speed than traditional setups. This efficiency allows manufacturers to respond quickly to market demands and reduce lead times, enhancing competitiveness. Moreover, the upgrade often comes with better energy efficiency, leading to cost savings on energy bills and a reduced environmental footprint. In summary, the transition to state-of-the-art manufacturing technology is not merely an optional investment; it is a strategic move that can drive significant improvements in efficiency, quality, and sustainability within the manufacturing sector.

Integrating new machinery into your manufacturing process can seem daunting, especially with the rapid advancements in technology like integrated calendering and slitting machines. According to a report by Smithers Pira, manufacturers that adopt modern machinery can increase production efficiency by up to 30%, significantly reducing operational costs. To harness these benefits, a structured approach is essential.

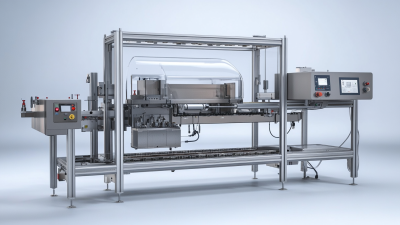

Begin by conducting a thorough assessment of your current setup. Identify bottlenecks and specific areas where the new technology can streamline operations. Collaborate with the equipment provider to gain insights into proper installation and maintenance practices. This collaborative effort not only enhances performance but also ensures a smoother transition.

**Tip:** Ensure that your staff is trained on the new machinery before it is operational. According to a study by the Manufacturing Institute, companies that invest in employee training see a 20% increase in productivity.

Next, implement the new machinery in stages rather than all at once. This phased approach allows for fine-tuning processes, minimizing disruptions to existing workflows. Monitor the performance closely using key performance indicators (KPIs) to measure improvements and make necessary adjustments.

**Tip:** Utilize real-time data tracking systems to evaluate the efficiency of your new machinery continuously. This will enable you to respond swiftly to any issues that arise, keeping your production streamlined and effective.

Proper maintenance of calendering and slitting machines is crucial to maximizing operational efficiency and ensuring the longevity of equipment. According to a report by MarketsandMarkets, the global market for manufacturing equipment is anticipated to reach $1.3 trillion by 2025, with advancements in machine technology directly impacting productivity. Regular maintenance practices not only prevent unexpected downtime but also enhance performance by keeping machinery in optimal condition. Implementing scheduled inspections and using genuine replacement parts can significantly reduce wear and tear.

In addition to preventative maintenance, calibration plays a vital role in maintaining the efficiency of these machines. A study by the Association for Manufacturing Technology indicates that manufacturers can achieve up to a 30% increase in production efficiency simply through regular calibration and alignment checks. Operators should routinely assess the tension settings and ensure that the temperature controls, essential for calendering processes, are accurately maintained. By adopting these maintenance strategies, manufacturers can optimize their processes, allowing for smoother operations and better end-product quality.

The landscape of manufacturing is undergoing a remarkable transformation, particularly with innovations in calendering and slitting technologies. As companies strive for efficiency and sustainability, advanced techniques in battery production are leading the charge. Recent studies indicate that the global battery production machine market is projected to grow significantly, from an estimated $13.26 billion in 2024 to approximately $37.59 billion by 2034. This robust growth highlights the increasing reliance on state-of-the-art manufacturing equipment to meet the rising demand for lithium-ion batteries, which are critical for numerous applications including electric vehicles and renewable energy storage.

Future trends in calendering and slitting technologies will likely focus on integrating advanced automation and enhanced energy efficiency features into production lines. The latest research suggests that dry electrode technologies are paving the way for more sustainable practices in battery manufacturing, reducing waste and energy consumption compared to traditional methods. As manufacturers adopt these innovations, they will not only improve throughput but also contribute to environmental sustainability, positioning themselves ahead in a rapidly evolving industrial sector.

The synergy of these cutting-edge technologies promises to revolutionize the manufacturing process, making it more adaptable and efficient for years to come.