Leave Your Message

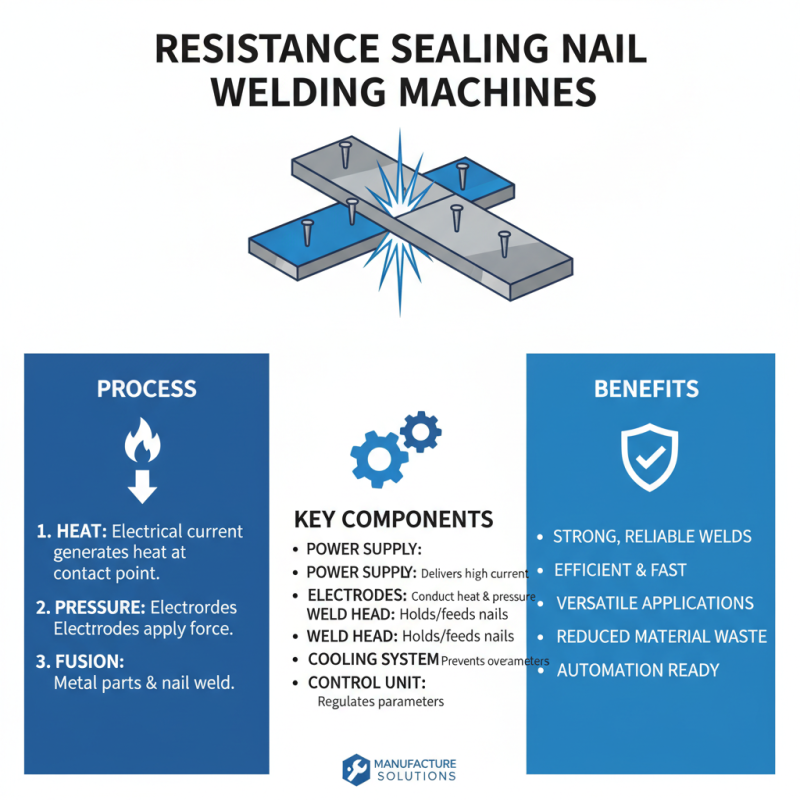

The Resistance Sealing Nail Welding Machine is an innovative tool in manufacturing. It is designed to efficiently join metal components using heat generated by electrical resistance. As industries evolve, the demand for precise and reliable welding methods increases. The Resistance Sealing Nail Welding Machine aims to meet these needs, ensuring durable connections.

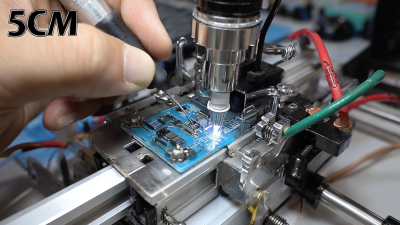

In practice, this machine operates by applying electrical current through the nail and the surfaces being joined. The heat produced melts the material at the joint, forming a strong bond. Workers often find this method more effective than traditional welding techniques. However, users should be cautious and mindful of safety protocols.

Despite its advantages, the Resistance Sealing Nail Welding Machine may require regular maintenance to function optimally. Some operators might struggle with adjustments, which can affect quality. Continuous training and awareness can mitigate these issues. Understanding how to effectively use this machine is vital for producing high-quality work.

A resistance sealing nail welding machine is a specialized tool. It is designed for joining materials through heat generated by electrical resistance. This machine typically works with metal components. It is efficient in producing strong, permanent bonds.

The process begins with the placement of nails and the workpieces. When the machine is activated, electrical current flows through the nails. This generates heat, melting the metal at the contact points. The molten metal fuses, creating a solid bond as it cools. This technique is widely used in various industries, including construction and manufacturing.

Tip: Always ensure that the components are clean before welding. Dirt can lead to weak seals.

Setting the correct current and pressure is vital. Too high a current can cause excessive heat. This may damage the workpieces. On the other hand, too low a current may not provide a strong bond.

Tip: Regular maintenance of the machine is important. This ensures optimal performance and longevity.

Improper adjustment can lead to inconsistent results. It is essential to monitor every weld closely. Each joint should meet quality standards to ensure reliability.

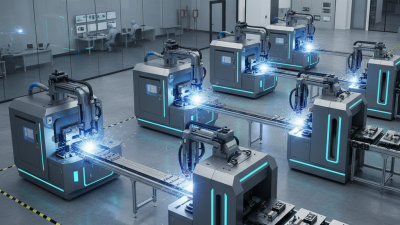

Resistance sealing nail welding machines are essential in various manufacturing settings. These machines utilize a specialized technique that combines heat and pressure to create strong, reliable welds. The key components of these machines greatly influence their performance and efficiency.

One major component is the welding transformer. It converts electrical energy into controlled heat. Reports indicate that transformers can vary in size and output, impacting the speed of the welding process. Another critical element is the electrode. The electrode’s material and shape affect the heat distribution during welding. Proper electrode maintenance is crucial, as even minor wear can lead to inconsistent welds.

Another vital component is the control system. Advanced control systems allow for precise adjustments to welding time and pressure. This adaptability can reduce material waste by ensuring optimal conditions for every weld. However, operators must remain vigilant. If settings are incorrect, the machine may produce defective nails, affecting overall productivity. Establishing a routine for monitoring these systems can mitigate potential issues and enhance welding outcomes.

Resistance sealing nail welding machines play a crucial role in manufacturing. They utilize a method known as resistance welding. This technique generates heat through electrical resistance, enabling the joining of materials. The machine applies pressure and electric current simultaneously. The result is a strong bond in a matter of seconds.

During operation, the process starts with precise alignment. Components must fit perfectly for effective welding. Too much pressure can cause deformation. Too little pressure results in weak joints. Operators must monitor the current closely. Variations can lead to inconsistent results.

An important factor is the choice of materials. Some combinations weld easily; others may require adjustments. Not all settings yield ideal outcomes. Operators should document their findings. This will help refine the process over time. The efficiency of resistance welding can improve significantly with experience and insight.

Resistance sealing nail welding technology finds its applications in various industries. This method creates strong, durable seals by welding nails to materials. It is commonly used in the production of automotive parts. These parts often require secure assembly to withstand harsh conditions. The effectiveness of this technology enhances the reliability of components.

Another application is in the construction field. Builders use this method for sealing panels and frames. It provides a seamless connection that improves insulation and water resistance. The precision of resistance welding minimizes defects. However, not all materials are suitable for this method. Certain factors, such as thickness and composition, can affect results.

Moreover, the adoption of this technology is growing in the appliance sector. Manufacturers aim for better durability and performance. With rising demands, the potential for improvement increases. Ongoing research is crucial to solve existing challenges. Understanding material behaviors during welding is essential. Even experienced professionals face unexpected issues at times. This technology continues to evolve, offering exciting possibilities.

Resistance sealing nail welding machines offer significant advantages in manufacturing processes. These machines utilize electrical resistance to generate heat for welding, ensuring robust and reliable joints. According to industry reports, these machines can improve production efficiency by up to 30%. This efficiency is crucial in high-volume production settings, where speed and quality are paramount.

One of the key benefits is the reduction in material wastage. Traditional welding methods often lead to excess byproducts. In contrast, resistance sealing nail welding minimizes this, saving resources. Reports indicate that companies adopting this technology have experienced a 15% decrease in material costs. Additionally, these machines reduce the energy consumption during the welding process, making them more environmentally friendly. The precise control of heat application prevents over-heating, which can be a common issue in traditional welding.

However, there are areas for improvement. Training operators is essential to maximize the potential of these machines. A lack of training can lead to operational errors. Moreover, while maintenance is relatively low, overlooking routine checks can cause breakdowns. Manufacturers need to remain vigilant to fully leverage the benefits of resistance sealing nail welding machines.