Leave Your Message

In the ever-evolving landscape of manufacturing, choosing the right welding method can significantly impact the quality, efficiency, and cost-effectiveness of production processes. Among the myriad options available, Ab Core Tab Welding stands out as the best choice for manufacturers seeking to enhance their output and maintain high standards. This innovative technique not only ensures superior bond strength and durability but also offers flexibility to accommodate a variety of materials and designs. With its unique benefits, Ab Core Tab Welding simplifies complex assembly processes while minimizing errors and rework. In this blog, we will delve into ten compelling reasons why Ab Core Tab Welding should be at the forefront of your manufacturing strategy, empowering you to make informed decisions that drive success in today’s competitive market.

Ab Core Tab Welding has emerged as a preferred technique in modern manufacturing, offering a myriad of advantages that cater to the demands of today’s industrial landscape. One of the primary benefits is its remarkable speed and efficiency. This method facilitates rapid assembly, significantly reducing production times while maintaining high-quality standards. As a result, manufacturers can respond more swiftly to market demands, which is essential in a climate that values agility and responsiveness.

Another key advantage of Ab Core Tab Welding is its ability to produce strong, durable joints. The technique ensures consistent fusion of materials, which translates to enhanced structural integrity in the final product. This reliability is crucial for industries where safety and performance are paramount, such as aerospace and automotive sectors. Moreover, the reduction of secondary processes not only cuts costs but also minimizes the potential for defects, further enhancing the appeal of Ab Core Tab Welding in manufacturing environments that prioritize efficiency and quality.

Ab Core Tab Welding stands out as a superior choice for boosting production efficiency and speed in manufacturing. This innovative technique enhances the overall workflow by streamlining the welding process, enabling faster and more precise assembly of components. According to industry analysis, adopting advanced welding methods like Ab Core Tab can reduce production lead times by up to 30%, which is crucial for manufacturers aiming to meet increasing market demands without sacrificing quality.

The integration of Ab Core Tab Welding not only accelerates production but also improves the durability and reliability of the final products. Reports highlight that companies implementing these methods have experienced a significant drop in defect rates—potentially as much as 25%—due to the consistent and controlled nature of the welding process. This efficiency translates to lower operational costs and improved profitability, making it an attractive option for businesses looking to enhance their manufacturing capabilities in a competitive landscape.

Ab Core Tab Welding has emerged as a leading choice for manufacturers seeking cost-effective solutions without compromising quality. One significant advantage of this welding technique is the reduction in material usage, which directly translates to lower production costs. By efficiently joining components with minimal waste, businesses can streamline their operations and allocate resources more effectively. This means that companies not only save on raw materials but also reduce their waste disposal expenses, enhancing their overall financial health.

Moreover, Ab Core Tab Welding contributes to faster production cycles, which can be a game-changer for businesses operating in competitive markets. With quicker setup times and reduced finishing processes, manufacturers can increase their output without the need for extensive labor or equipment investment. This efficiency leads to significant savings in labor costs and minimizes downtime, allowing companies to react swiftly to shifting market demands. The ability to deliver high-quality products promptly further bolsters a business's reputation, making Ab Core Tab Welding a preferred option for manufacturers focused on optimizing their budget and maximizing productivity.

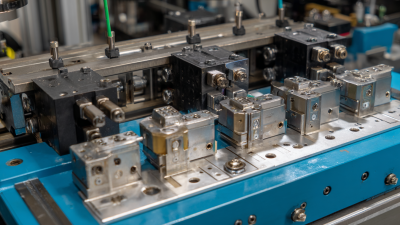

Ab Core Tab Welding has emerged as a pivotal technology in various manufacturing sectors due to its remarkable versatility. This process not only enhances structural integrity but also optimizes production efficiency across industries such as automotive, aerospace, and electronics. According to a report by MarketsandMarkets, the global welding equipment market is expected to grow from USD 18.16 billion in 2022 to USD 23.04 billion by 2026, largely fueled by innovations like Ab Core Tab Welding that cater to diverse applications.

In the automotive sector, for instance, Ab Core Tab Welding is increasingly used for its ability to create lightweight and durable components. The International Journal of Automotive Engineering notes that reducing vehicle weight by just 10% can lead to a 6-8% improvement in fuel efficiency. Similarly, in aerospace, the stringent standards for safety and performance make Ab Core Tab Welding a preferred choice for fabricating high-strength components, ensuring that manufacturers can meet regulatory requirements effectively. By leveraging this advanced welding technology, companies can not only enhance their product offerings but also achieve significant cost savings, affirming Ab Core Tab Welding's role as a transformative solution across multiple industries.

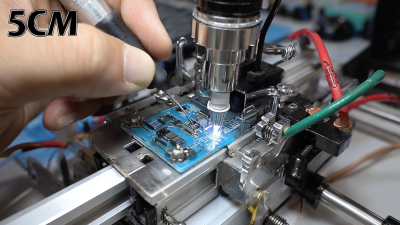

Ab Core Tab Welding techniques are making waves in the manufacturing industry, especially when it comes to ensuring unmatched quality and consistency. These advanced methods are designed to deliver precision and durability in critical applications. One significant aspect of Ab Core Tab Welding is its consistency across production runs; manufacturers can rely on uniform results, which reduces the need for extensive quality checks and rework. This reliability translates to decreased production costs and enhanced customer satisfaction, making it an attractive choice for businesses looking to streamline their manufacturing processes.

Recent advancements, such as the simulation of ultrasonic welding with copper joints using nanoparticle interlayers, highlight the importance of innovative welding techniques. The thermomechanical coupling models developed through cutting-edge software allow for a deeper understanding of how different materials interact during the welding process. This scientific approach mirrors the principles behind Ab Core Tab Welding, where techniques are continually refined to achieve optimal results. By focusing on quality and consistency, Ab Core Tab Welding not only meets but exceeds the rigorous demands of modern manufacturing.