Leave Your Message

In the rapidly evolving field of energy storage, the optimization of the Coin Cell R&D Line has become a focal point for improving production efficiency and enhancing overall output. Dr. Emily Chen, a leading expert in battery research and development, emphasizes the significance of this optimization by stating, "Streamlining our Coin Cell R&D Line not only accelerates the innovation cycle but also helps us meet the increasing demand for high-performance batteries." The intricate processes involved in developing and manufacturing coin cells require a careful balance of efficiency and quality, making best practices essential for any research and development team.

As the demand for compact and efficient energy storage solutions intensifies, the Coin Cell R&D Line must adapt to meet new challenges. Implementing essential tips for optimizing production can lead to significant cost savings and faster time-to-market for new technologies. With a focus on continuous improvement, researchers and engineers can refine their processes to ensure they are at the forefront of the industry. By leveraging expert insights and innovative methodologies, teams can enhance both the reliability and output of their coin cell products, ultimately contributing to advancements in various applications from consumer electronics to electric vehicles.

In conclusion, the journey towards an efficient Coin Cell R&D Line is one that requires dedication, expertise, and a commitment to progress. The insights shared by leaders in the field underscore the importance of this optimization, guiding organizations as they navigate the complex landscape of battery technology development.

The coin cell battery market has seen significant growth, with a projected compound annual growth rate (CAGR) of over 6% from 2021 to 2026, according to industry reports. This highlights the increasing demand for efficient coin cell R&D processes, as innovations in energy storage solutions are becoming critical for various applications, from consumer electronics to electric vehicles. Understanding the coin cell R&D process is essential, as it not only affects product development timelines but also allows companies to stay competitive in a rapidly evolving market.

To optimize the R&D process, companies should focus on a few key strategies. First, employing advanced simulation tools can significantly reduce the time required for testing and prototyping. By using computational models, teams can predict battery performance under various conditions, minimizing physical trial and error. Second, fostering cross-functional collaboration among chemists, engineers, and market analysts can enhance innovation and ensure that product development aligns with market needs.

Additionally, continuous quality improvement is vital. According to research, a focus on quality control during the R&D phase can lead to a reduction in production costs by up to 20%. Implementing regular audits and feedback loops can help identify potential inefficiencies early in the development process, ensuring a smoother transition to production. By understanding the importance of these elements in the coin cell R&D process, companies can achieve higher efficiency and better products.

This chart illustrates the efficiency of various stages in the coin cell research and development process, highlighting key areas for potential optimization.

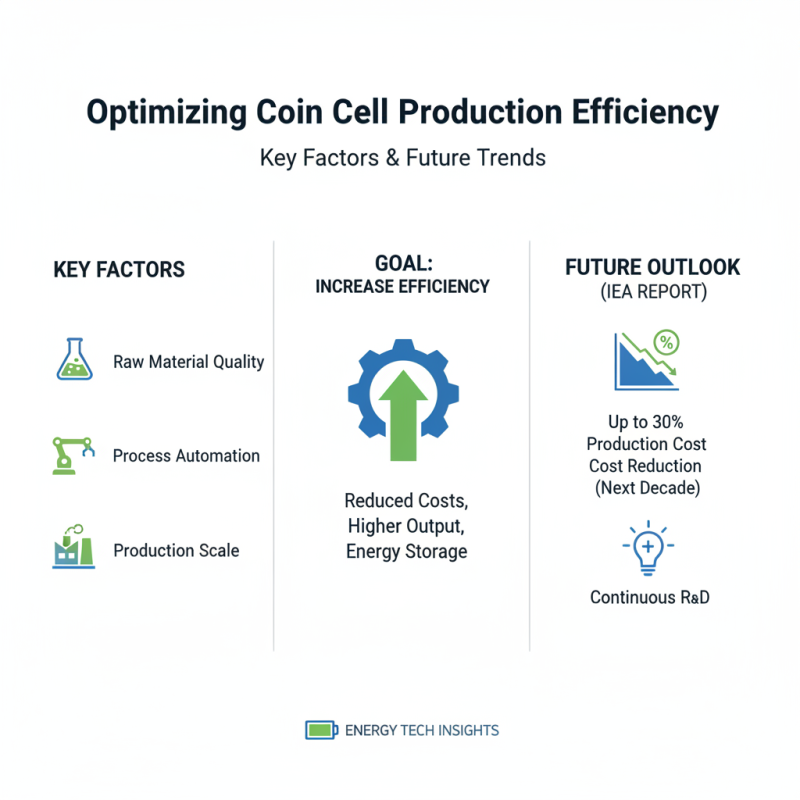

In the rapidly evolving field of battery technology, optimizing coin cell production efficiency is critical for manufacturers aiming to meet the growing demand for energy storage solutions. Key factors influencing this efficiency include raw material quality, process automation, and production scale. According to a report by the International Energy Agency, advancements in battery technology could reduce production costs by up to 30% over the next decade, emphasizing the importance of continual improvement in research and development lines.

Automation significantly enhances the precision and speed of coin cell production. A study by Research and Markets indicates that increased automation in battery manufacturing could lead to a 25% improvement in throughput while minimizing defects. Implementing real-time monitoring and control systems ensures consistent quality and adherence to production standards, which are vital for sustaining competitive advantage in the marketplace. Additionally, focusing on the optimization of chemical processes used in electrode production can result in a notable reduction in waste and an increase in overall yield.

Another key factor is the effective management of supply chains for critical raw materials. The fluctuations in lithium and other essential materials can heavily impact production costs and timelines. A recent analysis from BloombergNEF predicts that maintaining a robust supply chain could mitigate the risk of production delays by as much as 40%. As the industry transitions toward more sustainable practices, focusing on recycling and reusing materials will also play a pivotal role in enhancing production efficiency and reducing environmental impact in coin cell manufacturing.

In the rapidly evolving landscape of battery technology, optimizing the efficiency and production of coin cell manufacturing operations has become paramount. According to a report by Research and Markets, the global demand for batteries, particularly lithium coin cells, is expected to grow at a CAGR of 5.6% from 2020 to 2027. As manufacturers strive to meet this increasing demand, implementing streamlined operations is essential for maintaining competitive advantages.

One effective strategy for enhancing coin cell manufacturing efficiency is the adoption of automation technologies. The International Society of Automation highlights that incorporating automated systems can improve production rates by up to 30%, while also reducing human error and minimizing production costs. Additionally, integrating real-time data analytics in manufacturing processes allows companies to monitor performance metrics and identify bottlenecks quickly, facilitating prompt corrective actions that prevent downtime and inefficiencies.

Another vital aspect is the optimization of the supply chain. The battery manufacturing sector relies heavily on raw materials, and disruptions can significantly impact production schedules. According to a report from McKinsey, companies that streamline their supply chains can achieve a 20% reduction in operational costs. By leveraging strategic partnerships with suppliers and employing just-in-time inventory practices, manufacturers can enhance their responsiveness to demand fluctuations and ensure a steady flow of materials, ultimately boosting overall productivity and maintaining market relevance.

Implementing quality control measures in coin cell production is crucial for ensuring the reliability and performance of battery systems. According to a recent report by Grand View Research, the global coin cell battery market is projected to reach approximately $17.12 billion by 2025. As the demand for compact and efficient energy solutions grows, maintaining high quality in production processes becomes imperative. Effective quality control not only minimizes defects but also enhances overall production efficiency.

One best practice in quality control is to integrate automated inspection systems at various stages of the production line. These systems allow for real-time monitoring of critical parameters such as electrode thickness and electrolyte filling, ensuring consistency in quality. Another tip is to implement stringent testing protocols, including accelerated aging tests and capacity tests, to evaluate the performance of coin cells under different conditions. According to the Journal of Power Sources, batteries that undergo rigorous testing show a 30% improvement in longevity and customer satisfaction.

Additionally, fostering a culture of quality among employees can significantly influence production outcomes. Training sessions focused on quality standards and best practices can lead to greater awareness and adherence to protocols, ultimately boosting production efficiency. Leveraging data analytics can also identify trends in production defects, enabling teams to make informed decisions for continuous improvement. Emphasizing these quality control measures is essential for optimizing your coin cell R&D line efficiency and achieving high production standards.

| Parameter | Target Value | Actual Value | Status | Remarks |

|---|---|---|---|---|

| Cycle Time (mins) | 5 | 4.8 | On Track | Meeting efficiency targets |

| Defect Rate (%) | 1.0 | 1.2 | Above Target | Action needed to reduce defects |

| Production Yield (%) | 95 | 92 | Below Target | Investigate causes of yield loss |

| Equipment Downtime (hrs) | 2 | 1.5 | On Track | Well within acceptable limits |

| Employee Training (hrs) | 10 | 8 | Below Target | Schedule additional training sessions |

The efficiency of research and development (R&D) lines in the coin cell battery industry is critical to staying competitive in a rapidly evolving market. Advanced technologies can significantly enhance performance, streamline processes, and reduce production costs. According to a recent industry report, companies that integrate automation into their production lines can achieve up to a 30% increase in overall efficiency. Leveraging technologies such as AI-driven analytics and machine learning can enable manufacturers to predict equipment failures and maintenance requirements proactively, minimizing downtime and maximizing output.

Tips for optimizing your R&D line include implementing real-time monitoring systems. These systems allow for continuous oversight of production parameters, enabling quick adjustments based on data-driven insights. Moreover, investing in advanced materials analysis tools can aid in developing more efficient cell chemistries, which not only improves performance but also reduces waste during the manufacturing process.

Another key insight is to foster collaboration between R&D and production teams. By aligning goals and ensuring consistent communication, innovations can transition more smoothly from the laboratory to full-scale production. Implementing a feedback loop where production data informs R&D efforts can lead to iterative improvements and enhance the overall performance of the R&D line. Adopting these advanced technologies and strategies can streamline operations, reduce costs, and ultimately drive better market outcomes.