Leave Your Message

As the demand for energy storage solutions continues to soar, optimizing production processes has become crucial for manufacturers operating in the electric vehicle and renewable energy sectors. The 21700 Battery Pilot Line has emerged as a vital tool in enhancing production efficiency, allowing companies to streamline operations while maintaining high-quality standards. According to a report by the International Energy Agency (IEA), battery production capacity is expected to increase significantly, with the global battery market projected to reach $100 billion by 2025. Furthermore, a study by McKinsey highlights that optimizing production processes can reduce costs by up to 30%, making the adoption of advanced pilot lines like the 21700 an essential strategy. By leveraging the capabilities of the 21700 Battery Pilot Line, manufacturers can not only meet growing consumer demands but also stay ahead in a competitive landscape characterized by rapid technological advancements and sustainability challenges.

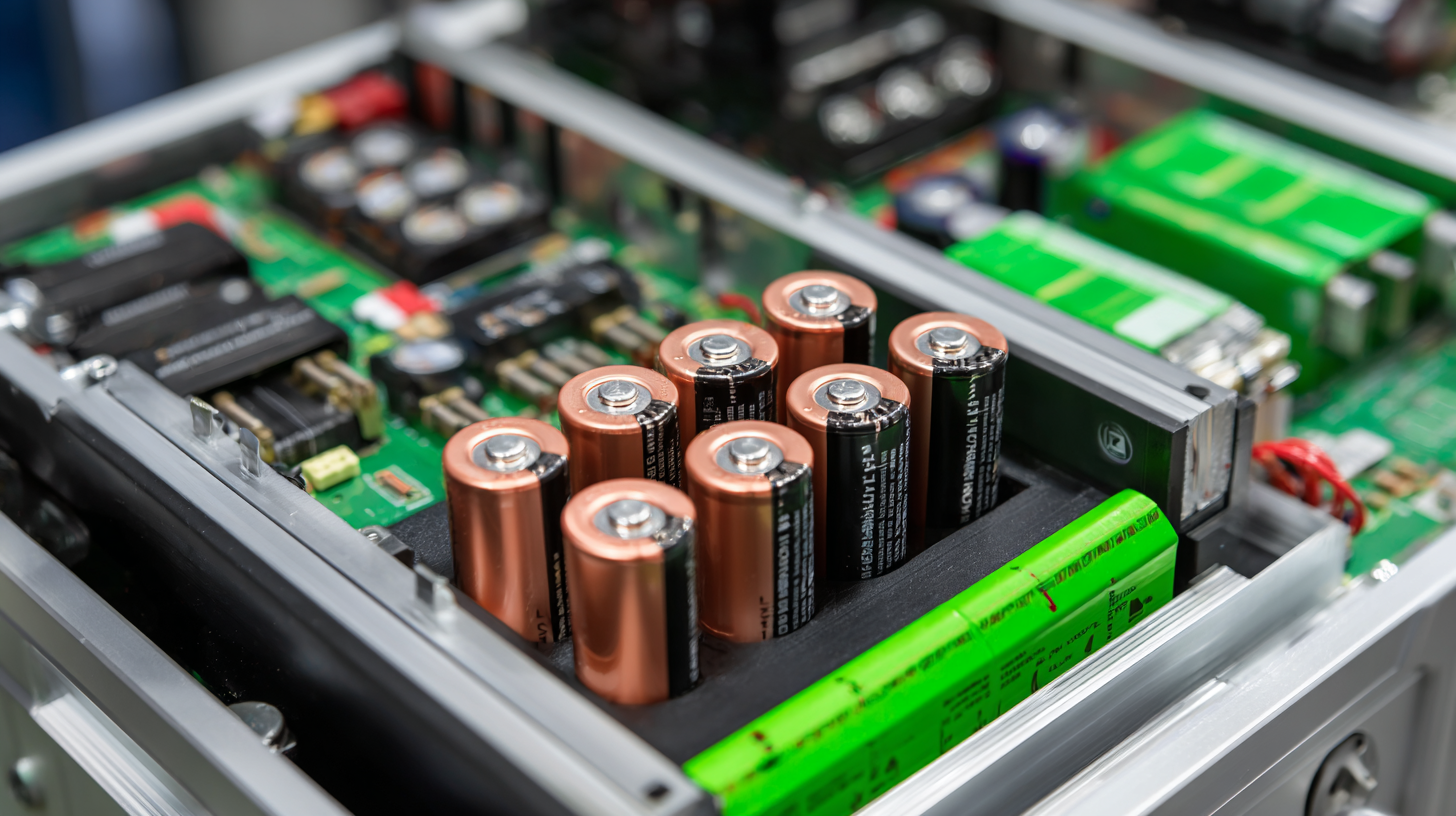

The 21700 battery pilot line represents a significant advancement in battery production technology, designed to streamline manufacturing processes while enhancing the overall efficiency of battery cell production. Understanding its basic components is crucial for any manufacturer looking to optimize their production capabilities. This pilot line integrates state-of-the-art machinery, automated systems, and precise control mechanisms to ensure consistent quality in battery cells. The standardization of processes allows for better scalability, enabling companies to adapt to increasing market demands without compromising on efficiency or quality.

Implementing the 21700 battery pilot line not only improves operational efficiency but also facilitates faster production cycles and reduces waste. By utilizing advanced analytics and real-time monitoring, manufacturers can quickly identify and rectify issues in the production process, leading to a more agile and responsive manufacturing environment. Additionally, with features such as modular equipment and flexible configurations, producers can easily adjust their workflows to accommodate different battery designs, making it a versatile solution in the ever-evolving battery landscape. This foundational understanding of the 21700 battery pilot line elements lays the groundwork for leveraging its full potential to drive production optimization.

| Dimension | Measurement | Optimal Value | Current Value |

|---|---|---|---|

| Cycle Time | Minutes | 15 | 20 |

| Yield Rate | Percentage | 98% | 95% |

| Energy Consumption | kWh | 100 | 120 |

| Downtime | Hours | 2 | 4 |

| Facility Footprint | Square Feet | 5000 | 5500 |

Identifying key efficiency metrics is crucial for optimizing the production process, especially when integrating new technologies such as the 21700 battery pilot line. One of the primary metrics to consider is the overall equipment effectiveness (OEE), which combines availability, performance, and quality. By assessing these components, manufacturers can pinpoint areas where production bottlenecks occur, allowing for targeted improvements. For instance, if availability is low due to frequent machine downtimes, addressing maintenance schedules or upgrading equipment may yield significant gains.

Identifying key efficiency metrics is crucial for optimizing the production process, especially when integrating new technologies such as the 21700 battery pilot line. One of the primary metrics to consider is the overall equipment effectiveness (OEE), which combines availability, performance, and quality. By assessing these components, manufacturers can pinpoint areas where production bottlenecks occur, allowing for targeted improvements. For instance, if availability is low due to frequent machine downtimes, addressing maintenance schedules or upgrading equipment may yield significant gains.

Another vital metric to track is cycle time. This measures the time it takes to produce a single unit and can reveal inefficiencies in the manufacturing process. By analyzing cycle time, organizations can determine if adjustments in workflow or staffing levels are necessary. Additionally, yield rates should be monitored to ensure that the number of defective products remains minimal. By focusing on these key metrics, companies can refine their strategies and enhance their production processes, ultimately leading to increased profitability and competitiveness in the battery market.

Implementing lean manufacturing principles in battery production can significantly enhance efficiency and reduce waste, particularly when utilizing the 21700 battery pilot line. Lean manufacturing focuses on optimizing processes by eliminating non-value-added activities, which can lead to a reduction in production costs and improved product quality. According to a report by McKinsey, companies that implement lean practices can achieve up to a 25% reduction in production costs and a 30% increase in productivity.

In the context of battery production, applying lean principles involves streamlining workflows, improving inventory management, and enhancing communication among teams. For instance, the use of just-in-time inventory systems can minimize storage costs and ensure that materials are available when needed, thereby reducing downtime. A study by the International Energy Agency indicates that adopting lean methodologies can result in a 15-20% increase in efficiency, which is crucial in the highly competitive battery manufacturing sector. By focusing on continuous improvement and utilizing data-driven decision-making, manufacturers can effectively optimize their production processes, leading to faster turnaround times and greater customer satisfaction.

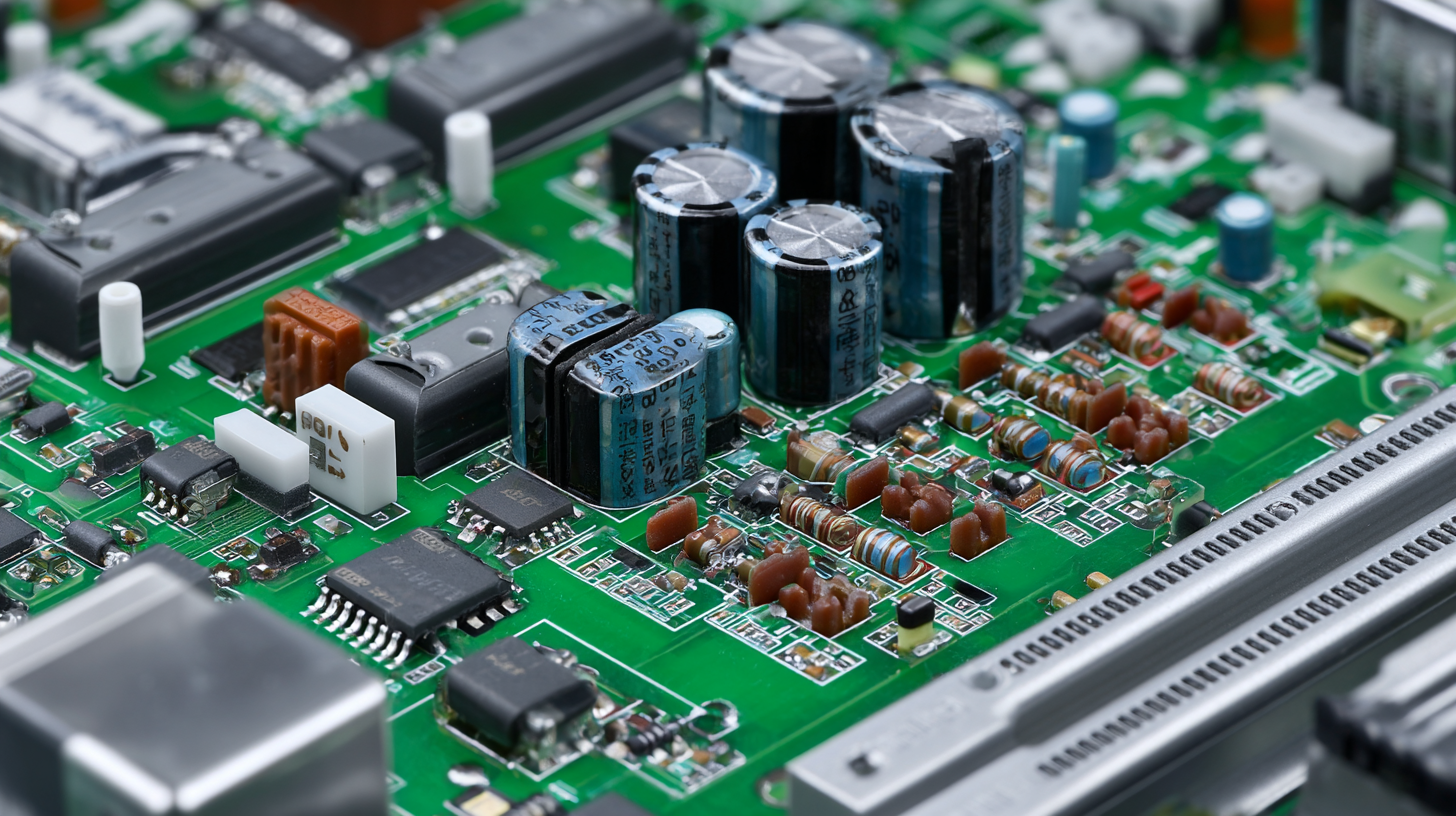

Integrating advanced automation technologies into the production process of the 21700 battery pilot line can significantly enhance efficiency and product quality. Automation tools such as robotics, machine learning algorithms, and real-time monitoring systems streamline operations, reducing manual intervention and minimizing errors. By implementing automated assembly lines, manufacturers can achieve higher throughput while ensuring consistency in the production of battery cells. This not only optimizes resource allocation but also accelerates the development cycle for new battery technologies.

Furthermore, advanced data analytics integrated within these automated systems allows for continuous improvement. By gathering data from every stage of the manufacturing process, manufacturers can identify bottlenecks and implement corrective measures swiftly. Predictive maintenance technologies can also be utilized to prevent equipment failures, ensuring that the production line runs smoothly without unnecessary downtime. Leveraging these automation technologies will not only enhance the production efficiency of the 21700 battery pilot line but also position companies to respond proactively to the evolving demands of the energy market.

Continuous improvement is crucial in optimizing production processes, particularly when integrating advanced technologies like the 21700 battery pilot line. Conducting regular reviews allows teams to assess current workflows, identify inefficiencies, and implement targeted strategies for enhancement. By fostering a culture of ongoing assessment, organizations can ensure that their production methods adapt to evolving industry standards and consumer demands.

Each improvement review should focus on key performance indicators specific to the production process. Engaging team members in these discussions not only provides diverse perspectives but also encourages a sense of ownership over changes. Tools such as process mapping and value stream analysis can be employed to visualize workflows, pinpoint bottlenecks, and establish benchmarks. Continuous feedback loops can further refine processes, enabling teams to make data-driven decisions that lead to sustainable efficiency gains.

Incorporating these practices within the framework of the 21700 battery pilot line not only enhances productivity but also heightens the quality of the final product. By systematically addressing issues and celebrating small victories, manufacturers can cultivate an environment conducive to innovation and resilience, ultimately leading to a more robust production workflow.