Leave Your Message

In today's rapidly evolving energy landscape, the demand for efficient and sustainable battery production has reached unprecedented heights. According to a report by BloombergNEF, investments in battery technologies are projected to exceed $300 billion by 2030, driven by the exponential growth of electric vehicles and renewable energy storage systems.

The 32140 Cylindrical Battery Pilot Line stands out as a crucial innovation that empowers manufacturers to optimize their production processes while meeting these soaring demands. By leveraging advanced manufacturing techniques and cutting-edge automation, this pilot line not only enhances scalability but also significantly reduces costs and waste associated with battery production.

As companies strive to improve energy density and cycle life for cylindrical cells, understanding how to fully utilize the capabilities of the 32140 Cylindrical Battery Pilot Line becomes imperative for maintaining a competitive edge in the booming battery market.

In today's rapidly evolving energy landscape, the demand for efficient and sustainable battery production has reached unprecedented heights. According to a report by BloombergNEF, investments in battery technologies are projected to exceed $300 billion by 2030, driven by the exponential growth of electric vehicles and renewable energy storage systems.

The 32140 Cylindrical Battery Pilot Line stands out as a crucial innovation that empowers manufacturers to optimize their production processes while meeting these soaring demands. By leveraging advanced manufacturing techniques and cutting-edge automation, this pilot line not only enhances scalability but also significantly reduces costs and waste associated with battery production.

As companies strive to improve energy density and cycle life for cylindrical cells, understanding how to fully utilize the capabilities of the 32140 Cylindrical Battery Pilot Line becomes imperative for maintaining a competitive edge in the booming battery market.

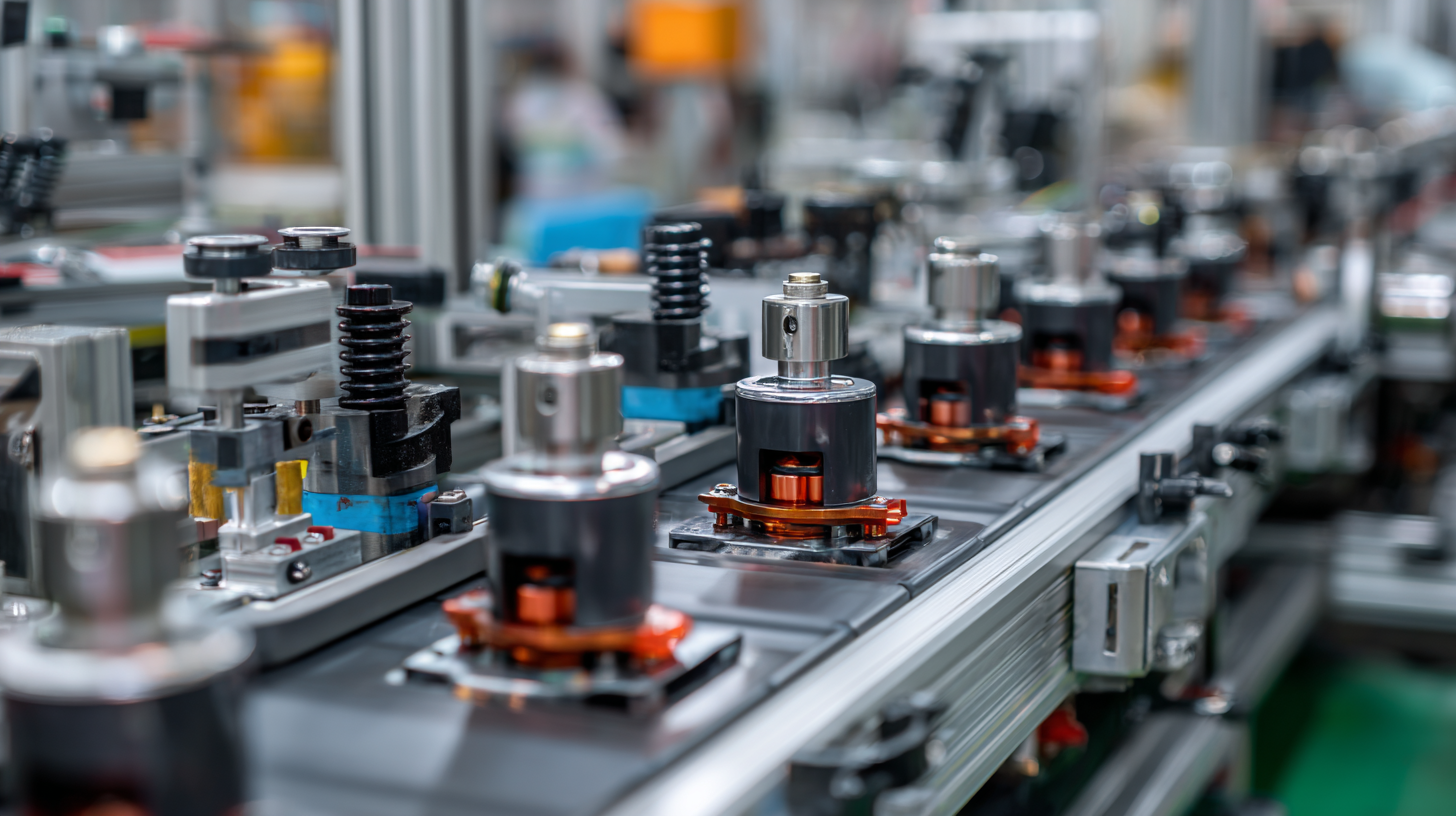

The 32140 cylindrical battery pilot line offers a remarkable opportunity for manufacturers aiming to enhance their production capabilities. Its key features include advanced automation, precise quality control, and the ability to rapidly prototype different battery specifications. Such adaptability not only streamlines the manufacturing process but also ensures that the end products meet the growing demands of various markets, including the emerging sodium-nickel battery sector.

The sodium-nickel battery market is projected to experience substantial growth, with its value increasing from $0.45 billion in 2022 to an anticipated $1.2 billion by 2030. This signifies a compound annual growth rate of 14.5% from 2024 to 2030, suggesting that the industry is poised for expansion. In this dynamic landscape, manufacturers leveraging the innovative features of the 32140 cylindrical battery pilot line can position themselves advantageously, catering to the rising demand while maintaining high standards of efficiency and performance in their production processes.

As the flexible battery market is projected to reach approximately $156.3 million in 2023, with a compound annual growth rate of 23.75% from 2024 to 2031, manufacturers are increasingly seeking innovative techniques to streamline production processes. One prominent approach is the implementation of automated and smart manufacturing solutions that enhance efficiency and precision in the battery production line. By adopting cutting-edge technologies, producers can optimize their workflows, reduce downtime, and improve overall product quality.

Central to these advancements is the establishment of a comprehensive, turnkey solution that encompasses the entire battery manufacturing process. This includes everything from raw material sourcing to final product assembly. By integrating automation, manufacturers can not only accelerate production timelines but also maintain consistent standards that meet the growing demand for flexible batteries in various applications. As the industry evolves, staying ahead of technological trends through innovation becomes crucial for companies aiming to retain a competitive edge in the rapidly expanding battery market.

The 32140 cylindrical battery pilot line is positioned at the forefront of energy storage innovation, with automation playing a crucial role in enhancing efficiency throughout the production process. According to a report by MarketsandMarkets, automated manufacturing systems can help reduce production costs by up to 30%, significantly impacting the overall profitability of battery production. By integrating advanced robotics and software solutions, manufacturers can achieve consistent quality and faster turnaround times, meeting the ever-increasing demand for energy-efficient storage.

Moreover, the implementation of automation in the 32140 battery pilot line streamlines operations, allowing for real-time data analysis and predictive maintenance. Research from McKinsey & Company indicates that companies leveraging advanced analytics in their manufacturing processes can improve productivity by up to 20%. Such improvements are essential for the rapidly growing electric vehicle market, projected to reach 33 million units by 2025, necessitating efficient battery production to keep pace with consumer demand. By maximizing automation, manufacturers can ensure they are at the cutting edge of this transformative industry.

The 32140 cylindrical battery pilot line represents a significant advancement in battery production technology, enabling manufacturers to achieve enhanced cost-effectiveness in their operations. By streamlining the production process and utilizing high-quality materials, this innovative line reduces waste and optimizes resource allocation. As a result, companies can lower their production costs while maintaining the performance and reliability of their battery products, positioning themselves competitively in a rapidly evolving market.

Additionally, the economic impact of the 32140 cylindrical battery line extends beyond initial production savings. The scalability of this technology allows businesses to adapt quickly to market demands, reducing lead times and increasing responsiveness to customer needs. The ability to produce batteries efficiently means that companies can meet growing energy storage requirements without incurring prohibitive costs. Ultimately, the financial benefits gained from implementing the 32140 pilot line can lead to increased profitability and a stronger market presence.

| Parameter | Value | Unit |

|---|---|---|

| Battery Production Capacity | 5000 | Units/Day |

| Cost per Battery | $8.50 | USD |

| Monthly Production Cost | $255,000 | USD |

| Return on Investment (ROI) | 18% | Annual |

| Energy Efficiency | 90% | Percentage |

| Average Lead Time | 7 | Days |

The future of battery technology is rapidly evolving, with innovations shaping not only production efficiency but also the overall performance of energy storage solutions. The 32140 cylindrical battery pilot line exemplifies this shift, combining cutting-edge manufacturing processes with quality control mechanisms that set the benchmark for the industry. According to a recent report by BloombergNEF, global demand for lithium-ion batteries is expected to reach over 2,000 GWh by 2030, creating an urgent need for scalable and efficient production lines like the 32140.

As automation and smart technologies integrate into battery manufacturing, the 32140 pilot line demonstrates how manufacturers can significantly reduce production costs while enhancing output quality. Industry studies have shown that modernized production techniques can improve cycle times by as much as 30%, highlighting the importance of embracing innovation. With sustainability becoming a crucial factor, the 32140 line also emphasizes the recycling and responsible sourcing of materials, aligning with the projected increase in electric vehicle (EV) adoption—estimated to be over 30% of new car sales by 2030 (McKinsey & Company). This ensures that the 32140 not only meets current market demands but also paves the way for a more sustainable and efficient future in battery technology.