Leave Your Message

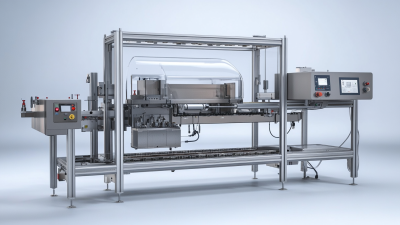

In the rapidly evolving field of battery technology, the optimization of production processes has become a critical factor in enhancing overall efficiency and reducing costs. As the demand for alternative energy sources continues to surge, the role of the Lab-Scale Battery Packaging Machine has emerged as a pivotal element in battery manufacturing. According to a recent report by the International Energy Agency (IEA), global battery demand is expected to double by 2030, driven by the accelerating transition to electric vehicles and renewable energy solutions. As such, optimizing the efficiency of lab-scale operations is essential for companies looking to maintain a competitive edge in this burgeoning market.

Research indicates that optimizing packaging machine performance can improve operational efficiency by up to 25%, a substantial increase that can lead to significant cost savings and reduced time-to-market for new products. With advancements in automation and machine learning, manufacturers are now better equipped to enhance the functionality of Lab-Scale Battery Packaging Machines, making them more adaptable to varying production needs. Furthermore, integrating data analytics into the operational framework can provide insights that streamline processes, reduce waste, and ensure consistent quality in battery output, aligning with the industry’s sustainability goals.

As manufacturers navigate these challenges, focusing on lab-scale efficiency is not just a necessity but a strategic imperative that could define the success of organizations in a fiercely competitive landscape. By leveraging cutting-edge technology and innovative practices, the optimization of Lab-Scale Battery Packaging Machines stands to revolutionize the industry, setting the pathway for a more sustainable energy future.

When it comes to optimizing throughput in lab-scale battery packaging machines, identifying key performance indicators (KPIs) is essential. KPIs such as cycle time, yield rate, and equipment utilization provide insights into operational efficiency.

By measuring the cycle time, manufacturers can determine how long it takes to complete a packaging task, allowing for adjustments that minimize delays. A lower cycle time not only increases throughput but also enhances overall productivity.

Yield rate is another critical KPI that reflects the percentage of products that meet quality standards without rework. By monitoring this metric, organizations can identify areas for improvement in the packaging process, ensuring that defects are minimized and resources are not wasted. Equipment utilization, on the other hand, assesses how effectively the machine's capacity is being used. Maximizing utilization through scheduling and process optimization can lead to significant increases in throughput, making it crucial for manufacturers aiming for efficiency in battery packaging operations.

Reducing downtime in lab scale battery packaging requires a keen understanding of material flow and process optimization. As automated material handling equipment continues to expand—projected to reach a market value of USD 51.22 billion by 2030—it's essential that laboratory environments embrace these advancements to enhance efficiency.

Implementing advanced plant layout and process flow design services can significantly boost productivity, minimize operational costs, and ensure seamless movement of materials and personnel.

Tips: Evaluate your current workflow to identify bottlenecks and implement automated solutions tailored to your lab's specific needs. Utilize data-driven insights to optimize your supply chain for improved agility, which can drastically reduce delays and enhance material throughput.

Furthermore, incorporating intelligent automation powered by AI can lead to predictive maintenance strategies, enabling laboratories to foresee potential issues before they escalate. In this rapidly evolving landscape, staying ahead means prioritizing flexibility and efficiency to adapt to changing demands in battery production. This proactive approach not only mitigates downtime but also positions labs to respond more effectively to market challenges.

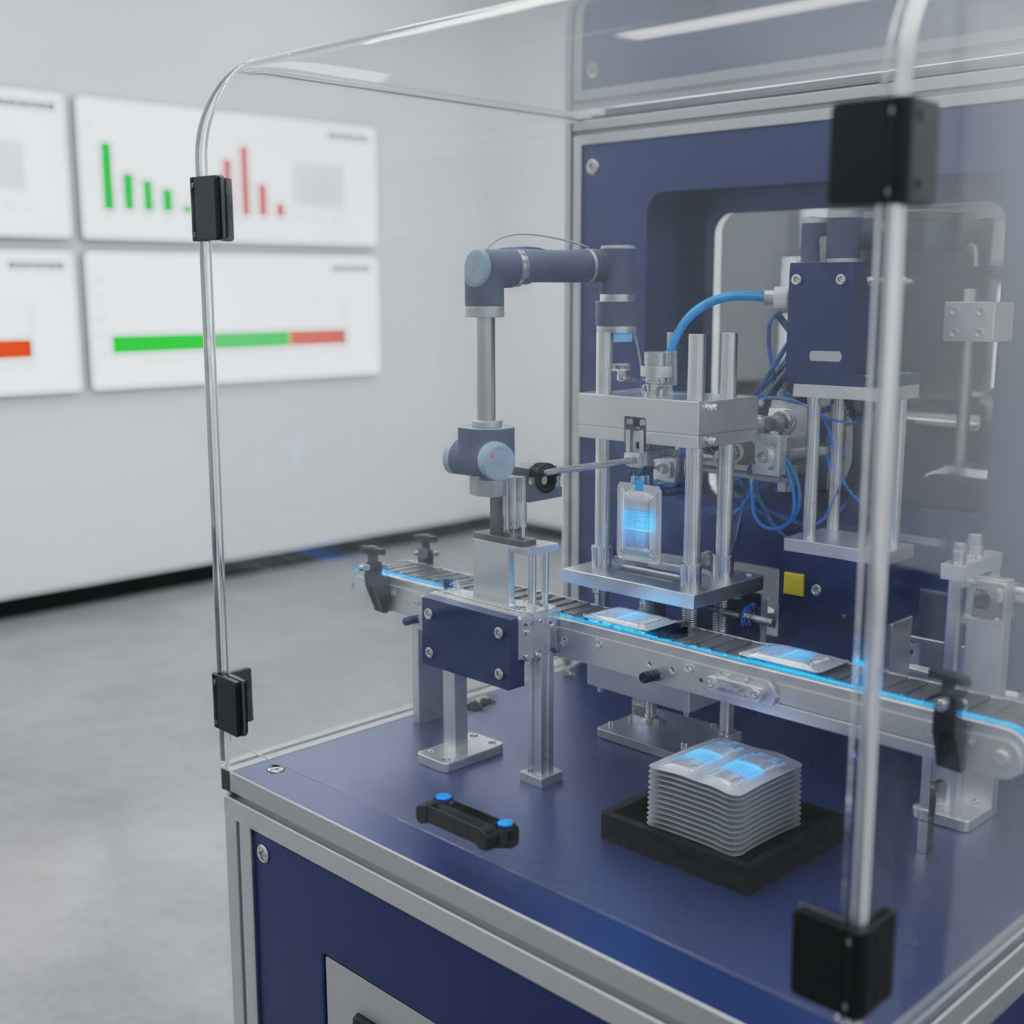

In the quest for optimizing lab scale battery packaging machine efficiency, integrating

automation emerges as a game changer. Smart technology solutions not only enhance operational speed

but also improve precision in the packaging process. By employing advanced robotics and AI algorithms, manufacturers can significantly reduce

human error, streamline workflows, and boost productivity. These automated systems are designed to adapt to different production scenarios, allowing

for quick adjustments that meet varying packaging requirements.

Tips for Implementation:

To effectively implement automation in your packaging process, start by assessing your current workflows.

Identify bottlenecks where automation can make the most impact. Additionally, investing in training for your staff ensures they are equipped

to leverage new technologies effectively.

Another crucial aspect is selecting the right technology that aligns with your production goals.

Look for solutions that offer scalability, enabling your operations to grow without a complete overhaul of existing systems.

Monitoring performance through real-time data analytics can further aid in optimizing efficiency

by providing insights into where improvements can be made.

Quality control is crucial in battery pack production, especially as we aim to optimize lab-scale battery packaging machine efficiency. By implementing strict quality control metrics, manufacturers can ensure that each battery pack meets the established standards for performance and reliability. Regular inspections and testing at various stages of the production process can help identify defects early, minimizing waste and improving overall production efficiency.

Tips for maintaining quality control in battery pack production include utilizing standardized operating procedures (SOPs) to streamline processes, investing in automated inspection systems, and establishing a feedback loop with production teams to address any recurring issues. Additionally, employing statistical process control can help monitor key performance indicators and enable real-time adjustments to production methods.

Another essential aspect of ensuring consistency is thorough training for operators and staff involved in the production process. Equip them with the necessary skills and knowledge about battery technology and quality standards to create a culture of excellence. Regular training sessions can empower your team to recognize potential quality issues swiftly and take corrective actions, ultimately enhancing the efficiency of your lab-scale operations.

As the demand for energy storage solutions continues to grow, the battery packaging industry is increasingly focusing on sustainability. According to a recent report by Grand View Research, the global battery packaging market is projected to reach $15.2 billion by 2027, with a compound annual growth rate (CAGR) of 10.8%. This growth is propelling manufacturers to innovate eco-friendly packaging solutions that not only meet efficiency goals but also minimize the environmental impact.

One significant trend in sustainable battery packaging practices is the use of biodegradable materials and recyclable components. A study published in the Journal of Cleaner Production found that implementing biodegradable packaging could reduce carbon footprint by up to 30%. Innovations such as plant-based plastics and recycled metals are now being integrated into the packaging process, aligning with circular economy principles. Furthermore, the adoption of techniques like light-weighting can enhance efficiency, as lighter packaging consumes less energy during transportation, thus reducing overall emissions throughout the supply chain.

Additionally, IoT technology is being employed to monitor packaging performance and streamline logistics. By utilizing data-driven insights, companies can optimize their processes, reducing waste and increasing efficiency. Research from IBM indicates that organizations that embrace sustainable practices can increase their operational efficiency by as much as 25%, giving a competitive edge in a market that is increasingly scrutinizing environmental impacts.