Leave Your Message

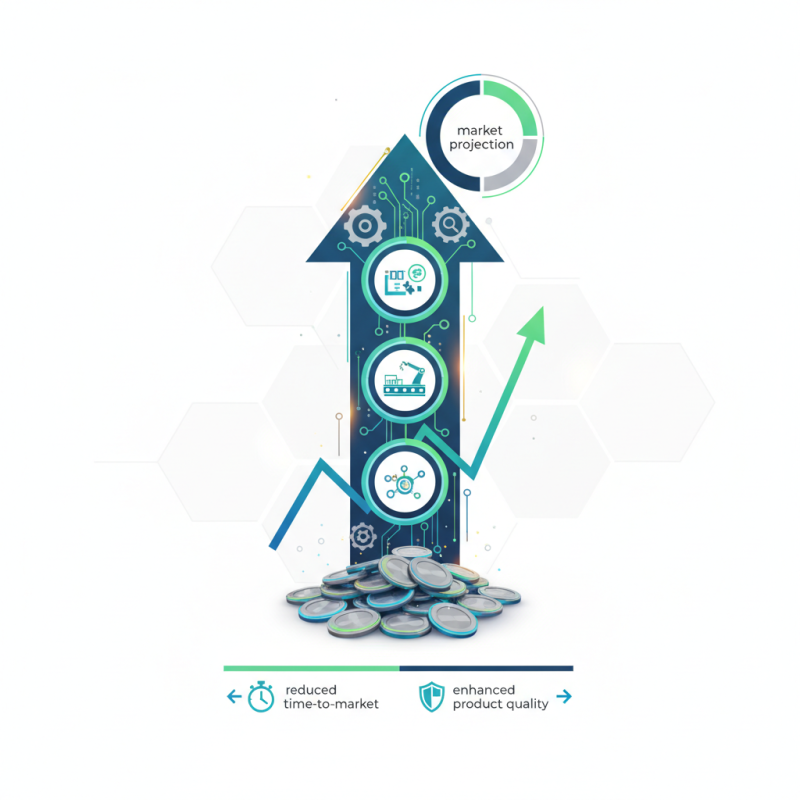

The demand for advanced energy storage solutions has seen a remarkable increase in recent years, with the global coin cell market projected to reach $2.9 billion by 2026, growing at a CAGR of 6.5% from 2021 to 2026. This surge is primarily driven by the expanding applications of coin cells in consumer electronics, medical devices, and wearable technology, necessitating rigorous research and development strategies. To remain competitive in this rapidly evolving landscape, optimizing the Coin Cell R&D Line is pivotal, as it directly impacts both production efficiency and product performance.

Efficient R&D practices in coin cell manufacturing are crucial not only for reducing time-to-market but also for enhancing product quality and reliability. Recent studies indicate that companies employing streamlined R&D processes can reduce development times by up to 30%, significantly lowering costs while improving innovation rates. By focusing on key areas such as material selection, manufacturing techniques, and quality assurance, organizations can ensure their coin cell products meet the stringent requirements of modern applications. Optimization of the Coin Cell R&D Line is not just a technical necessity, but a strategic imperative that can lead to sustainable growth and market leadership in the energy storage sector.

Optimizing your coin cell research and development (R&D) line is crucial for enhancing efficiency and performance. One of the key areas for improvement is the material selection process. Streamlining this phase can significantly reduce development time and costs. By implementing a systematic approach to evaluate materials based on performance criteria, such as cycle life and conductivity, teams can make informed choices that align with project goals.

Tips: Conduct regular reviews of your material database to ensure it is up to date with the latest research findings. This allows for quicker access to high-performing materials and fosters innovation within the R&D team.

Another critical area is the testing and validation phase. Traditional testing methods can be time-consuming, leading to delays in the development timeline. Improving these processes by adopting advanced characterization techniques can expedite the assessment of cell performance. Moreover, automating data analysis can reduce human error and enhance the reproducibility of results.

Tips: Invest in training for your team on the latest testing technologies. This not only increases operational efficiency but also empowers team members to contribute to continuous improvement initiatives actively.

The optimization of coin cell manufacturing processes hinges significantly on the implementation of advanced technologies. By integrating automation and robotics within the production line, companies can enhance precision and reduce the margin for error during the assembly of coin cells. This level of automation not only streamlines operations but also minimizes the potential for contamination, thereby ensuring a higher quality product. Advanced machine learning algorithms can analyze real-time data to predict equipment failures and optimize maintenance schedules, translating to less downtime and improved overall efficiency.

Additionally, the integration of novel materials and production techniques is crucial for enhancing performance characteristics of coin cells. Utilizing state-of-the-art coating technologies can improve the uniformity and density of electrode materials, leading to better energy output and longevity of the cells. Furthermore, the exploration of alternative manufacturing processes, such as 3D printing for specific components, opens new avenues for customization and optimization of design. The synergy between advanced technologies and innovative material science presents an unprecedented opportunity to advance coin cell performance while promoting sustainability within the manufacturing framework.

In optimizing your coin cell R&D line, streamlining workflows is essential for reducing lead times and maximizing output. According to a report by an industry research firm, companies that implement lean manufacturing principles can experience a 30% reduction in lead times while increasing overall productivity by up to 25%. This improvement stems from creating standardized procedures, enhancing communication across teams, and leveraging data analytics to identify bottlenecks in the production process.

Adopting advanced project management tools can significantly aid this transition. For instance, integrating real-time tracking systems allows researchers and engineers to monitor workflow status, adjust priorities, and allocate resources more efficiently. A recent survey highlighted that organizations using these systems reported a 40% increase in on-time project completion rates. By fostering an environment where data-driven decisions are the norm, companies can align their R&D activities more closely with market demands, ultimately leading to faster turnaround times and heightened operational efficiency.

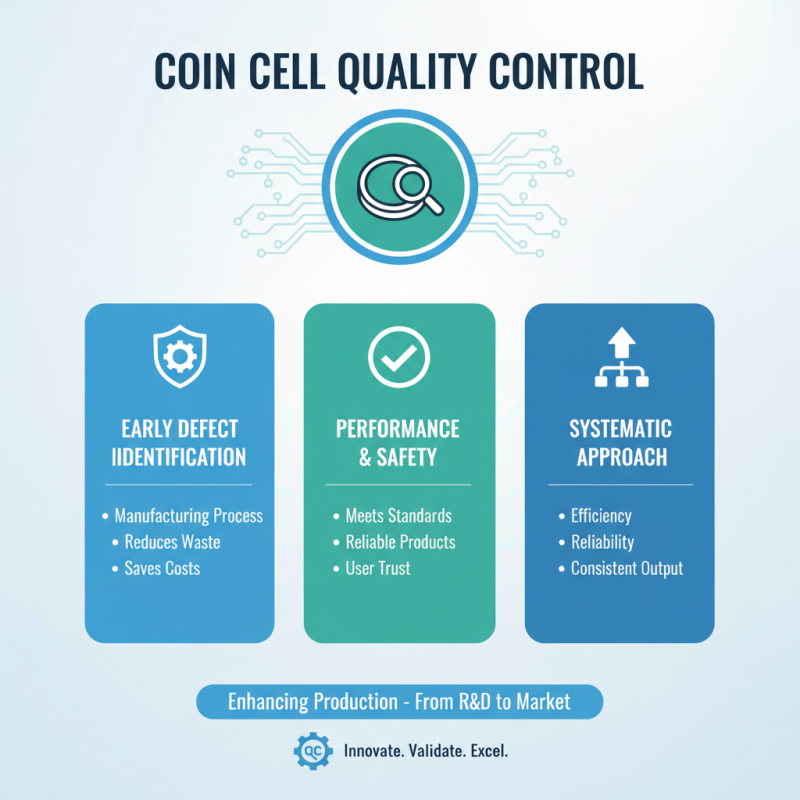

In the fast-paced world of coin cell research and development, establishing robust quality control measures is paramount to ensuring consistent performance across production lines. Quality control not only helps in identifying defects early in the manufacturing process but also guarantees that the end products meet safety and performance standards. Implementing a systematic approach to quality assurance can enhance both the efficiency and reliability of the production process.

Tips for effective quality control include integrating automated testing systems that provide real-time feedback on product performance. This allows for immediate adjustments to be made during manufacturing, minimizing waste and improving yield rates. Regular training sessions for employees on quality standards and testing procedures can also foster a culture of quality awareness, empowering team members to take ownership of their roles in the production line.

Additionally, it’s crucial to establish standard operating procedures (SOPs) that outline each step of the manufacturing process. These SOPs should include guidelines for material selection, testing thresholds, and documentation of results. By promoting a consistent methodology, you not only streamline processes but also enhance traceability, making it easier to identify areas for improvement. Investing in these quality control measures will ultimately lead to a more efficient R&D line and higher-performing coin cells.

Training and development for R&D staff play a pivotal role in optimizing the efficiency and performance of any coin cell R&D line. By equipping team members with the latest knowledge in battery technologies, materials science, and production methodologies, organizations can foster a culture of continuous improvement and innovation. Regular workshops, hands-on training sessions, and collaborative projects enable researchers and engineers to refine their skills, adapt to emerging trends, and effectively solve complex R&D challenges.

Moreover, implementing a structured mentorship program can significantly enhance the learning curve for less experienced staff. Pairing seasoned experts with newcomers not only accelerates the onboarding process but also encourages the sharing of best practices and innovative problem-solving approaches. This dynamic exchange can lead to fresh perspectives and inventive solutions, reinforcing the team's collective capability. By investing in the professional growth of R&D personnel, companies can maximize their research output and drive the development of high-performance coin cell technologies.

| Training Program | Duration (hours) | Objectives | Expected Outcome | Evaluation Method |

|---|---|---|---|---|

| Introduction to Coin Cell Technology | 4 | Understand basic principles of coin cell design | Improved understanding of materials and processes | Quiz and feedback session |

| Advanced Material Selection | 6 | Explore material properties and their impact | Enhanced material choice for R&D | Case study analysis |

| Testing and Evaluation Techniques | 8 | Learn various testing methodologies | Improved testing accuracy and efficiency | Performance metrics analysis |

| Innovation Strategies Workshop | 5 | Foster innovative thinking in R&D | Foster a culture of innovation | Group project presentation |

| Lean Manufacturing Principles | 7 | Reduce waste in R&D processes | Increased operational efficiency | Process mapping and improvement plan |