Leave Your Message

The introduction of the 4680 Tabless Battery Lab Line technology marks a significant advancement in battery manufacturing, promising to enhance efficiency and reduce costs dramatically in the electric vehicle (EV) sector. According to a report by BloombergNEF, the global electric vehicle market is projected to grow to 54 million units by 2040, increasing the demand for more efficient battery solutions. The 4680 Tabless Battery design improves energy density and simplifies production processes, which can potentially reduce manufacturing costs by up to 30%. Additionally, a study from the International Energy Agency indicates that innovations in battery technology such as the Tabless design can lead to a 25% increase in range for EVs. As manufacturers seek to scale this technology, leveraging the full potential of the 4680 Tabless Battery Lab Line will be crucial in meeting the rising consumer expectations and sustainability goals of the automotive industry.

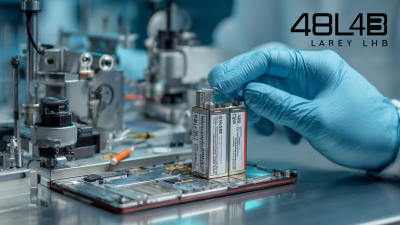

The 4680 tabless battery technology, developed by Tesla, represents a significant advancement in energy storage solutions. Unlike traditional battery designs that utilize tabs to connect cells, the tabless architecture integrates the battery's design for greater efficiency and performance. According to a report from IDTechEx, this innovative design allows for a reduction in manufacturing costs by up to 20%, making electric vehicles (EVs) more accessible and economically viable. Moreover, the seamless flow of electrons within the tabless structure enhances energy density and accelerates charge times, which is critical as the demand for high-performance batteries grows.

Additionally, the tabless design improves thermal management within the battery, reducing the risk of overheating—a common issue in conventional batteries. Research from Benchmark Mineral Intelligence highlights that Tesla's new manufacturing process not only reduces cell production times but also enhances the overall lifespan of the battery by approximately 30%. This is particularly advantageous in the rapidly evolving EV market, where battery durability and performance are paramount. Overall, the 4680 tabless battery technology marks a pivotal shift towards more efficient energy solutions, propelling the industry's commitment to sustainable transportation.

The 4680 Tabless Battery Lab Line Technology represents a significant advancement in battery design, primarily due to its innovative tabless architecture. This design eliminates the need for traditional tabs, which are the small metal connectors that usually link the battery cell to its electrodes. By doing so, the tabless design enhances electrical conductivity and reduces internal resistance, leading to improved energy efficiency. According to a report by BloombergNEF, cars with new battery technologies like the 4680 can achieve a 20% increase in range compared to their predecessors, making this design a game-changer for electric vehicles.

Moreover, the tabless design facilitates faster manufacturing processes, which is crucial in scaling up production to meet growing demand. A study from the International Energy Agency (IEA) indicates that battery production must increase at least sixfold by 2030 to reach global climate goals. By streamlining the production stages and reducing material costs, the 4680 Tabless Battery can provide manufacturers with the means to produce larger volumes without sacrificing quality. Additionally, the increased surface area of the electrodes contributes to a higher energy density, potentially allowing for battery sizes to decrease while maintaining or increasing energy output, thus enhancing the overall performance of electric vehicles.

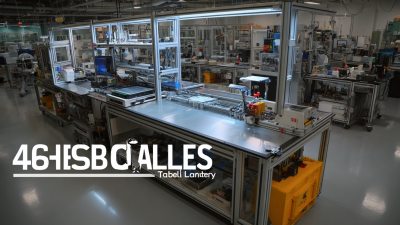

The implementation of efficient manufacturing processes in battery lab lines is crucial for optimizing the production of advanced battery technologies such as the 4680 tabless battery. According to a report by BloombergNEF, the global battery demand is expected to surge, with an estimated requirement of 3,000 GWh per year by 2030. This unprecedented growth necessitates innovative manufacturing solutions that enhance output while minimizing costs.

One promising approach is the application of automation and precision engineering in battery lab lines. By integrating advanced robotics and real-time monitoring systems, manufacturers can significantly reduce cycle times and waste. For instance, a study by McKinsey highlights that companies adopting these technologies can achieve production efficiency improvements of up to 30%. Furthermore, the transition to a tabless design in the 4680 battery not only simplifies the manufacturing process but also enhances energy density, leading to better performance and longer ranges for electric vehicles.

Additionally, the emphasis on sustainable practices in manufacturing processes cannot be overlooked. A report from the International Energy Agency (IEA) indicates that energy-efficient production methods can reduce carbon emissions by up to 20% in battery manufacturing. By focusing on sustainable efficiency, manufacturers can address both economic and environmental challenges while meeting the growing demands of the EV market.

The integration of automation in the production of the 4680 tabless battery promises to revolutionize the efficiency of battery manufacturing. According to a report by the International Energy Agency, the global demand for batteries is projected to rise by 30% annually, necessitating advanced production methods that can keep pace with this growth. Automation technologies, such as robotics and AI-driven systems, can significantly reduce labor costs and production times. For instance, automated assembly lines can operate at a speed that increases output by up to 50%, as noted in a study by McKinsey & Company.

Moreover, the implementation of automated quality control systems ensures all produced batteries meet stringent safety and performance standards, reducing waste and rework. A survey from Deloitte indicates that companies adopting automation in their manufacturing processes have seen a 15% reduction in operational costs while enhancing product consistency. As battery manufacturers transition to automated solutions, they not only optimize production efficiency but also position themselves to better respond to the rapidly increasing global battery market. The 4680 tabless battery's design, combined with these technological advancements, creates a pathway for sustainable growth in the energy sector.

| Dimension | Current Value | Target Improvement | Strategy for Improvement |

|---|---|---|---|

| Production Cycle Time (hours) | 4 | 2 | Implement automated handling systems |

| Yield Rate (%) | 85 | 95 | Enhance quality control measures |

| Energy Efficiency (%) | 75 | 90 | Invest in high-efficiency machinery |

| Employee Productivity (units/hour) | 10 | 15 | Automate repetitive tasks |

| Downtime (hours/week) | 10 | 2 | Implement predictive maintenance |

The introduction of the 4680 tabless battery technology has revolutionized the landscape of battery production, particularly in electric vehicles. Performance metrics are critical in evaluating the efficiency gains from this innovative design. According to a recent report by Benchmark Mineral Intelligence, the tabless structure of the 4680 battery allows for a 16% increase in energy density compared to traditional battery designs. This increase translates not only to longer driving ranges but also to reduced material costs during production, as fewer materials are required to achieve the same power output.

Moreover, efficiency gains can be observed in the manufacturing process itself. Tesla's internal data highlights that the production line for the 4680 battery can achieve a throughput rate that is up to 100% greater than conventional lithium-ion battery lines. This enhanced efficiency is expected to facilitate a reduction in manufacturing costs by up to 30%, according to a report from the International Energy Agency. By optimizing the production process and lowering costs, manufacturers can significantly improve their competitive edge in the rapidly evolving electric vehicle market.