Leave Your Message

Ab Core Tab Welding is a critical technique in the manufacturing sector, especially within industries such as aerospace and automotive, where structural integrity is paramount. According to a report by MarketsandMarkets, the global welding market is projected to grow from $29.3 billion in 2020 to $37.1 billion by 2025, highlighting the increasing significance of advanced welding techniques.

Ab Core Tab Welding is a critical technique in the manufacturing sector, especially within industries such as aerospace and automotive, where structural integrity is paramount. According to a report by MarketsandMarkets, the global welding market is projected to grow from $29.3 billion in 2020 to $37.1 billion by 2025, highlighting the increasing significance of advanced welding techniques.

Mastering the nuances of Ab Core Tab Welding not only enhances production efficiency but also ensures compliance with stringent quality standards. Innovative techniques in this area can mitigate common challenges such as distortion and weld defects, ultimately leading to improved product performance and safety. With the industry continuously evolving, adopting best practices in Ab Core Tab Welding is essential for organizations aiming to maintain a competitive edge and uphold high manufacturing standards. As we explore various strategies and innovations, this guide aims to equip professionals with the knowledge necessary to excel in Ab Core Tab Welding.

Ab core tab welding is an essential skill in the fabrication industry, focusing on the joining of materials with precision. Understanding the fundamentals of this technique lays the groundwork for mastering advanced applications.

One key aspect is the selection of appropriate materials and tools, which can vary based on the thickness and type of the tabs involved. Familiarity with different welding methods, such as TIG or MIG, is crucial for achieving strong and durable welds that meet industry standards.

Tips for beginners include practicing on scrap materials to build confidence before working on actual projects. This not only helps in understanding the heat settings and weld pool dynamics but also allows for experimentation with different techniques in a low-pressure environment. Additionally, maintaining a clean workspace and equipment ensures that the welding process is smooth and effective.

Another important practice is learning to read and interpret welding symbols and specifications. This knowledge is vital for ensuring that the welds meet dimensional tolerances and strength requirements. Regularly reviewing these basics can elevate a welder's understanding and execution of ab core tab welding, leading to better overall results in projects.

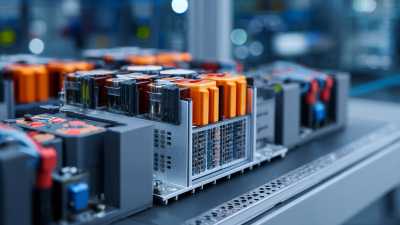

Mastering AB core tab welding requires more than just skill; it also hinges on the essential tools and equipment utilized in the process. According to a report from the American Welding Society, the right equipment can enhance productivity by up to 30%, significantly impacting the quality of welds produced. Key tools include automated welding machines, which are crucial for consistent deposition rates and penetration depth, ensuring that the quality of every weld meets rigorous industry standards.

Additionally, protective gear is indispensable in this demanding environment. The National Institute for Occupational Safety and Health emphasizes the importance of using high-quality welding helmets and respiratory protection. Studies show that proper protection can reduce the risk of occupational hazards by as much as 50%, thereby promoting a safer work environment. Investing in top-tier equipment not only bolsters production efficiency but also prioritizes the health and safety of professionals engaged in AB core tab welding, ultimately leading to better results and a more sustainable practice.

Additionally, protective gear is indispensable in this demanding environment. The National Institute for Occupational Safety and Health emphasizes the importance of using high-quality welding helmets and respiratory protection. Studies show that proper protection can reduce the risk of occupational hazards by as much as 50%, thereby promoting a safer work environment. Investing in top-tier equipment not only bolsters production efficiency but also prioritizes the health and safety of professionals engaged in AB core tab welding, ultimately leading to better results and a more sustainable practice.

Tab welding is a critical process in various manufacturing sectors, and enhancing joint strength is paramount for ensuring structural integrity. One innovative technique to achieve this is the use of advanced materials for the tabs themselves. Steel alloys that exhibit higher tensile strength can significantly improve the robustness of the joints. Additionally, selecting compatible filler materials that match the parent metals can optimize the weld strength, reducing the likelihood of brittle fractures.

Another promising approach involves the implementation of precision welding technologies, such as laser welding or ultrasonic welding. These methods allow for better control of heat input, minimizing thermal distortion and maximizing joint quality. Coupled with precise robotic positioning, these techniques can ensure uniform weld penetration, ultimately leading to stronger and more reliable joints. Moreover, integrating real-time monitoring systems can help in detecting any anomalies during the welding process, thus allowing for immediate adjustments and preventing weak joints from forming.

| Technique | Description | Benefits | Joint Strength Improvement (%) |

|---|---|---|---|

| Laser Welding | Utilizes a high-energy laser beam to create a strong joint. | High precision and minimal distortion. | 30% |

| TIG Welding | Tungsten Inert Gas welding provides a clean weld area. | Excellent for thin materials and control over the heat. | 25% |

| Friction Stir Welding | A solid-state joining process using a rotating tool. | Strong joints with a very low risk of defects. | 35% |

| Plasma Arc Welding | Utilizes a constricted arc to melt the metal. | High heat concentration allows for deeper penetration. | 28% |

In the realm of ab core tab welding, precision and consistency are paramount for achieving high-quality results. According to the American Welding Society, a mere 0.1 mm deviation can compromise the structural integrity of the weld, emphasizing the need for meticulous attention to detail during the welding process. Implementing best practices such as thorough joint preparation and consistent equipment calibration can significantly enhance the quality of the welds produced.

**Tips:** Always ensure that the welding surfaces are clean and free from contaminants like rust or oil. Conduct regular maintenance on your welding equipment to keep settings accurate and consistent. Also, utilizing advancements in automation can reduce human error, resulting in a more uniform welding output.

Additionally, employing real-time monitoring technologies can aid in maintaining precise parameters throughout the welding process. A report by the International Institute of Welding highlighted that companies utilizing feedback mechanisms saw a reduction in defects by up to 30%. Training staff on the importance of maintaining consistent heat input and travel speed can also lead to improved weld quality.

**Tips:** Create a standardized training program for welders, focusing on the critical aspects of precision in welding. Use visual aids and practical demonstrations to reinforce techniques that promote accuracy in every weld.

When engaging in Ab Core Tab welding, safety should always be the foremost priority. Before starting any welding project, it's essential to don the appropriate personal protective equipment (PPE), including a welding helmet, gloves, and protective clothing to shield against sparks and UV radiation. Additionally, ensuring a well-ventilated workspace minimizes the risk of inhaling harmful fumes emitted during the welding process. Familiarizing oneself with the Material Safety Data Sheets (MSDS) for materials being welded can provide crucial information regarding potential hazards and safe handling practices.

When engaging in Ab Core Tab welding, safety should always be the foremost priority. Before starting any welding project, it's essential to don the appropriate personal protective equipment (PPE), including a welding helmet, gloves, and protective clothing to shield against sparks and UV radiation. Additionally, ensuring a well-ventilated workspace minimizes the risk of inhaling harmful fumes emitted during the welding process. Familiarizing oneself with the Material Safety Data Sheets (MSDS) for materials being welded can provide crucial information regarding potential hazards and safe handling practices.

Another vital safety tip is to inspect tools and equipment before use. Ensuring that the welding machine is functioning correctly and that cables and hoses are intact helps to prevent accidents. It's also important to establish a clear and organized workspace, free from clutter that could pose tripping hazards or obstruct emergency exits. Implementing safety procedures, such as having a fire extinguisher readily available and knowing emergency contacts, can further enhance safety during Ab Core Tab welding, ultimately fostering a more secure working environment.