Leave Your Message

When it comes to industrial applications, the Resistance Sealing Nail Welding Machine stands out as a vital tool that enhances efficiency and productivity in various manufacturing processes. As technology continues to advance, recognizing the key features of these machines becomes essential for businesses looking to invest in reliable and effective welding solutions. In this guide, we will explore five critical attributes that distinguish the best Resistance Sealing Nail Welding Machines on the market today. From their operational efficiency and durability to advanced safety features and versatility, understanding these characteristics will empower manufacturers to make informed decisions that will ultimately lead to improved output and quality. Join us as we delve into the essential elements that define top-of-the-line Resistance Sealing Nail Welding Machines, ensuring your investment meets the demands of your specific applications.

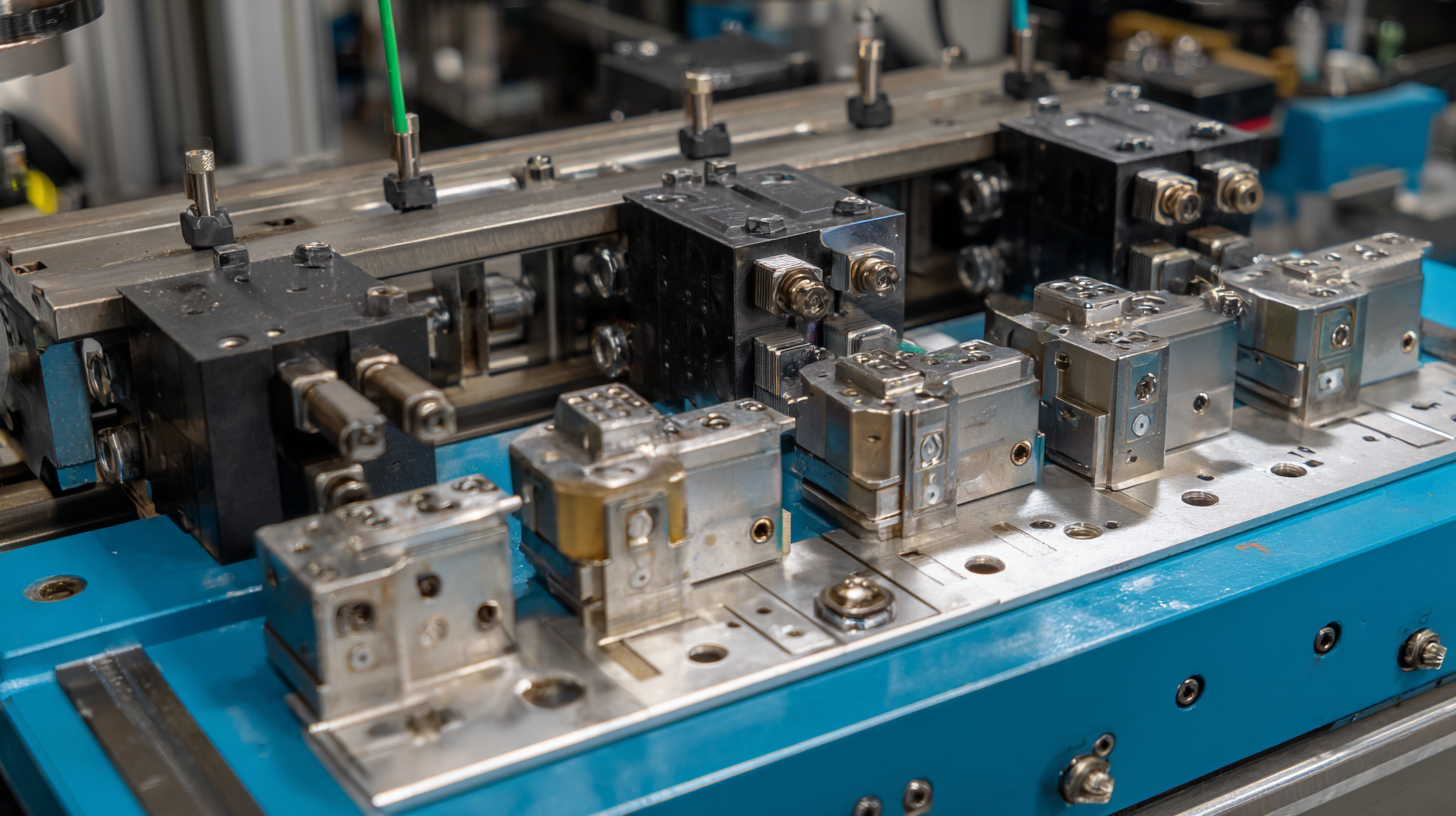

High-quality resistance sealing nail welding machines play a pivotal role in various industrial applications, enhancing both efficiency and precision. One of the primary benefits of these machines is their ability to create strong, durable welds with minimal thermal distortion. This is crucial in industries such as automotive and construction, where the integrity of the assembly is paramount. The precision offered by resistance welding minimizes the need for post-weld processing, saving time and resources while ensuring that the final products meet stringent quality standards.

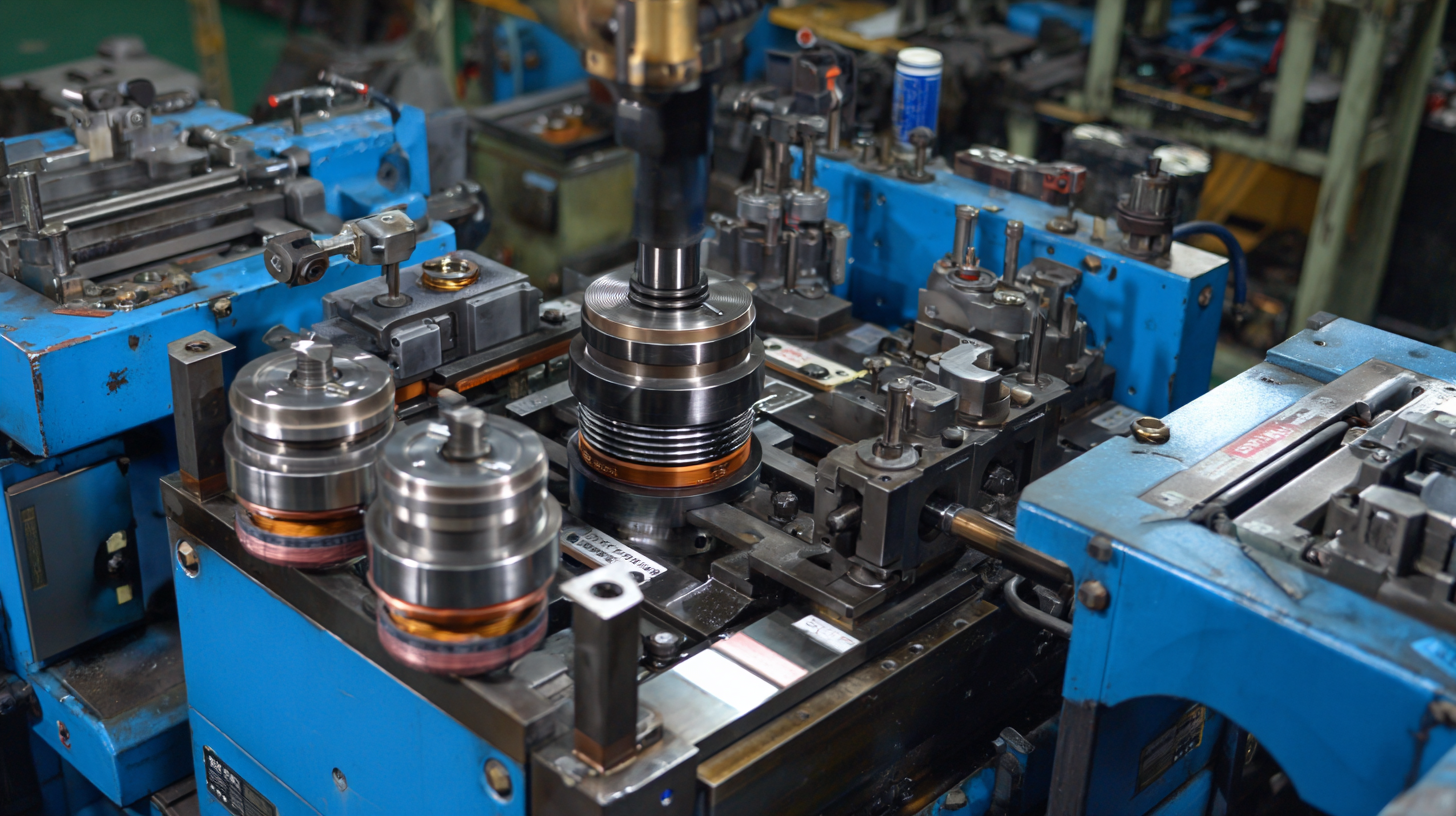

Another significant advantage is the versatility of resistance sealing nail welding machines. They can adapt to a range of materials, making them suitable for diverse applications. This adaptability allows manufacturers to utilize these machines in different production environments, from small workshops to large-scale factories. Additionally, the automation features of these machines reduce labor costs and human error, improving overall productivity. As industries continue to evolve, investing in high-quality resistance sealing nail welding technology becomes essential for businesses striving to maintain competitive advantages and deliver top-notch products.

| Feature | Description | Benefits |

|---|---|---|

| High Efficiency | Rapid sealing process to enhance production speed. | Increased output and reduced labor costs. |

| Precision Control | Advanced control systems for consistent welding performance. | Improved product quality and reduced material waste. |

| Durability | Robust design for long-term industrial use. | Reduced maintenance costs and downtime. |

| Versatility | Compatible with various nail types and materials. | Flexibility in production and application variety. |

| Safety Features | Integrated safety mechanisms to protect operators. | Enhanced workplace safety and compliance with regulations. |

When selecting a resistance sealing nail welding machine, understanding the top industry standards and certification requirements is crucial. Compliance with these standards ensures not only the safety and reliability of the equipment but also its efficiency during operation. The American National Standards Institute (ANSI), for example, sets forth guidelines that facilitate consistent quality and interoperability among welding machines. These standards cover various aspects, including design, construction, and operational capabilities, which are vital for maintaining high production quality and minimizing downtime.

Moreover, adhering to certifications such as ISO 9001 can provide a competitive edge in the marketplace. This certification signifies that a manufacturer adheres to best practices in quality management, giving customers confidence in their purchase decisions. Additionally, UL (Underwriters Laboratories) certification is essential, indicating that a welding machine meets rigorous safety standards. By investing in equipment that meets these recognized certifications, businesses can ensure optimal performance and longevity, ultimately leading to increased productivity and reduced costs over time.

When selecting a resistance sealing nail welding machine, understanding the essential technical specifications is crucial for ensuring optimal performance. A high-quality nail welding machine typically features a robust power supply, with specifications that allow for consistent and reliable welding across various materials. Notably, machines equipped with advanced inverter technology have shown to enhance energy efficiency by up to 30%, making them not only powerful but also cost-effective in the long run.

Another vital aspect to consider is the welding speed and penetration depth. Machines that offer adjustable parameters enable operators to configure the settings based on the material thickness, achieving better results in shorter timeframes. Industry reports indicate that advanced models, which allow for real-time adjustments, can improve productivity by as much as 20%. Furthermore, portability features become increasingly significant, especially in industries where on-site welding is common. Lightweight designs that incorporate ergonomic handles greatly enhance maneuverability, leading to reduced operator fatigue and increased efficiency.

In addition, safety features should not be overlooked. Modern machines often come with enhanced safety protocols, such as automatic shut-off systems and overload protection. These features help reduce the risk of accidents and ensure that operators can work confidently. Overall, investing in a welding machine with these essential specifications can lead to significant improvements in overall performance and safety in nail welding operations.

This bar chart illustrates the essential technical specifications of the best resistance sealing nail welding machines, showcasing key features such as power output, welding speed, temperature control range, weight, and durability. These parameters are crucial for achieving optimal performance in nail welding processes.

When considering the optimal method for joining materials, resistance sealing nail welding machines have emerged as a modern alternative to traditional welding. Unlike conventional welding methods that rely heavily on heat generation through extensive equipment, resistance sealing offers a faster, more efficient approach. By using a direct electrical current, these machines minimize thermal distortion and provide cleaner welds, resulting in stronger joints and reduced material waste.

Tip: When choosing between resistance sealing and traditional welding, it's important to evaluate the specific materials you'll be working with. Resistance sealing is particularly effective for thin materials that are sensitive to heat, making it ideal for industries like automotive and electronics.

Additionally, resistance sealing machines often come equipped with advanced control systems that allow for precise settings tailored to each application. This level of customization not only enhances the quality of the welds but also increases productivity by allowing for quicker adjustments during the welding process.

Tip: Regular maintenance and calibration of resistance sealing machines can significantly improve their performance and longevity. Investing time in ensuring that your equipment is in optimal condition will pay off in terms of efficiency and weld quality.

Proper maintenance of resistance sealing nail welding machines is vital for ensuring their longevity and optimal performance. Regular cleaning of the welding tips and ensuring that the machine is free from dust and debris can significantly reduce wear and tear. This practice not only enhances the welding quality but also minimizes the chances of unexpected breakdowns that can disrupt productivity. Operators should be trained to perform these cleaning routines as part of their daily responsibilities, promoting a proactive maintenance culture within the workplace.

Additionally, routine inspection of electrical components is essential. Checking connections for wear, ensuring that wiring is intact, and looking for any signs of overheating can prevent major failures. It’s advisable to have a scheduled maintenance plan, where professional technicians carry out more in-depth checks to identify potential issues before they escalate. By fostering a comprehensive maintenance program, businesses can extend the life of their resistance sealing nail welding machines while maintaining consistent operational efficiency.