Leave Your Message

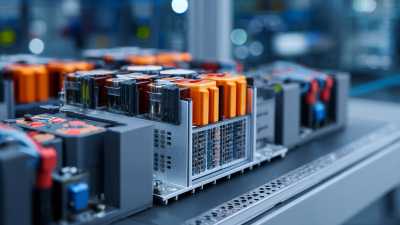

The 32140 Tabless Battery Pilot Line represents a significant leap in battery technology, poised to transform the energy sector through innovative design and manufacturing processes. According to a recent report by the International Energy Agency (IEA), the demand for advanced battery solutions is expected to increase dramatically, with estimates predicting a market growth rate of over 25% annually through 2030. This surge is driven by the accelerating adoption of electric vehicles (EVs) and renewable energy storage systems, which necessitate high-performance, cost-effective batteries. The 32140 Tabless Battery technology, noted for its reduced internal resistance and improved thermal management, could potentially increase energy density by up to 50%, as highlighted in the latest research by the Department of Energy. As industries strive for more efficient and sustainable energy solutions, the pilot line serves as a critical step toward commercializing groundbreaking innovations that could reshape the future of energy storage.

The 32140 Tabless Battery Pilot Line is revolutionizing the energy storage landscape through its innovative manufacturing techniques. Unlike traditional battery designs that require extensive connections and tabs, the tabless architecture streamlines production while enhancing efficiency. According to a recent report by BloombergNEF, the global lithium-ion battery market is projected to reach $1.2 trillion by 2030, partly fueled by such advancements that improve scalability and reduce costs. This pilot line represents a significant leap forward in the race to develop sustainable and efficient energy solutions.

One of the most intriguing aspects of the 32140 Tabless Battery is its potential to enhance thermal management. By eliminating tabs, the innovative design allows for better heat dissipation and increases the overall safety of the battery. In fact, a study from the National Renewable Energy Laboratory indicates that effective thermal management can improve battery life by up to 30% in electric vehicles. This focus on safety and longevity is essential as the industry moves towards more powerful and sustainable energy sources.

Tips: When considering battery options, always look for designs that prioritize safety and efficiency. Staying updated on manufacturing innovations can also help inform your choices. Furthermore, assess the longevity metrics of battery technologies to ensure you invest in sustainable solutions for the future.

The innovative advancements in battery technology are paving the way for more efficient energy solutions. A significant contributor to this evolution is the integration of digital technology, which plays a crucial role in enhancing battery performance and longevity. The 32140 Tabless Battery Pilot Line exemplifies how the combination of meticulous design and cutting-edge digital tools can lead to a new generation of batteries that are not only more efficient but also environmentally sustainable.

One pivotal aspect of leveraging digital technology is the use of data analytics and machine learning algorithms. These tools enable engineers to monitor battery performance in real time, optimizing charge cycles and improving energy distribution. Furthermore, predictive analytics can identify potential failures before they occur, allowing for proactive maintenance strategies that keep operations running smoothly.

**Tips:** To maximize battery efficiency in your own devices, consider using energy-saving settings and regularly updating software. Additionally, store your devices in moderate temperatures to prevent overheating, which can degrade battery life. Lastly, avoid completely draining your battery before recharging, as this can negatively impact its overall health.

The tabless battery design represents a significant advancement in the pursuit of sustainability in energy solutions. One of the primary benefits of this innovative approach is its reduction in material waste. By eliminating tabs, which traditionally connect cells and contribute to manufacturing excess, the tabless design maximizes the use of battery components, ultimately leading to fewer resources consumed in production. This streamlined process not only enhances energy efficiency during operation but also lessens the overall environmental footprint of battery manufacturing.

Furthermore, the environmental impact of tabless batteries extends beyond their production. These batteries are engineered for improved thermal management and energy density, which means they require less frequent replacements and can provide longer-lasting performance. This longevity translates to less electronic waste and lower emissions associated with production and disposal over time. By aligning with sustainability goals, the tabless battery innovation could pave the way for a cleaner, more efficient energy landscape, addressing pressing environmental challenges while meeting growing global energy demands.

The advancement of energy solutions relies heavily on collaborative approaches among researchers, engineers, and industry stakeholders. The development of the 32140 Tabless Battery Pilot Line exemplifies how teamwork can drive innovation in energy storage technologies. By pooling expertise and resources, organizations can overcome challenges inherent in battery design and manufacturing, ultimately leading to more efficient and sustainable energy solutions.

Tips for fostering collaboration include establishing clear communication channels among team members and setting shared goals that align with the vision of future energy innovations. Creating an inclusive environment where diverse ideas are welcomed can also spark creativity, leading to breakthroughs that might not have emerged in isolation. Additionally, integrating feedback mechanisms allows teams to iterate quickly on prototypes, enhancing the development process.

Investing in collaborations not only accelerates innovation but also helps in building a more resilient energy future. By working together, stakeholders can address pressing energy challenges—such as sustainability and efficiency—bringing us closer to effective solutions that will power our world. Engaging in partnerships can also leverage additional funding and resources, further enhancing the research and development landscape.

| Innovation Aspect | Description | Expected Impact | Collaboration Type |

|---|---|---|---|

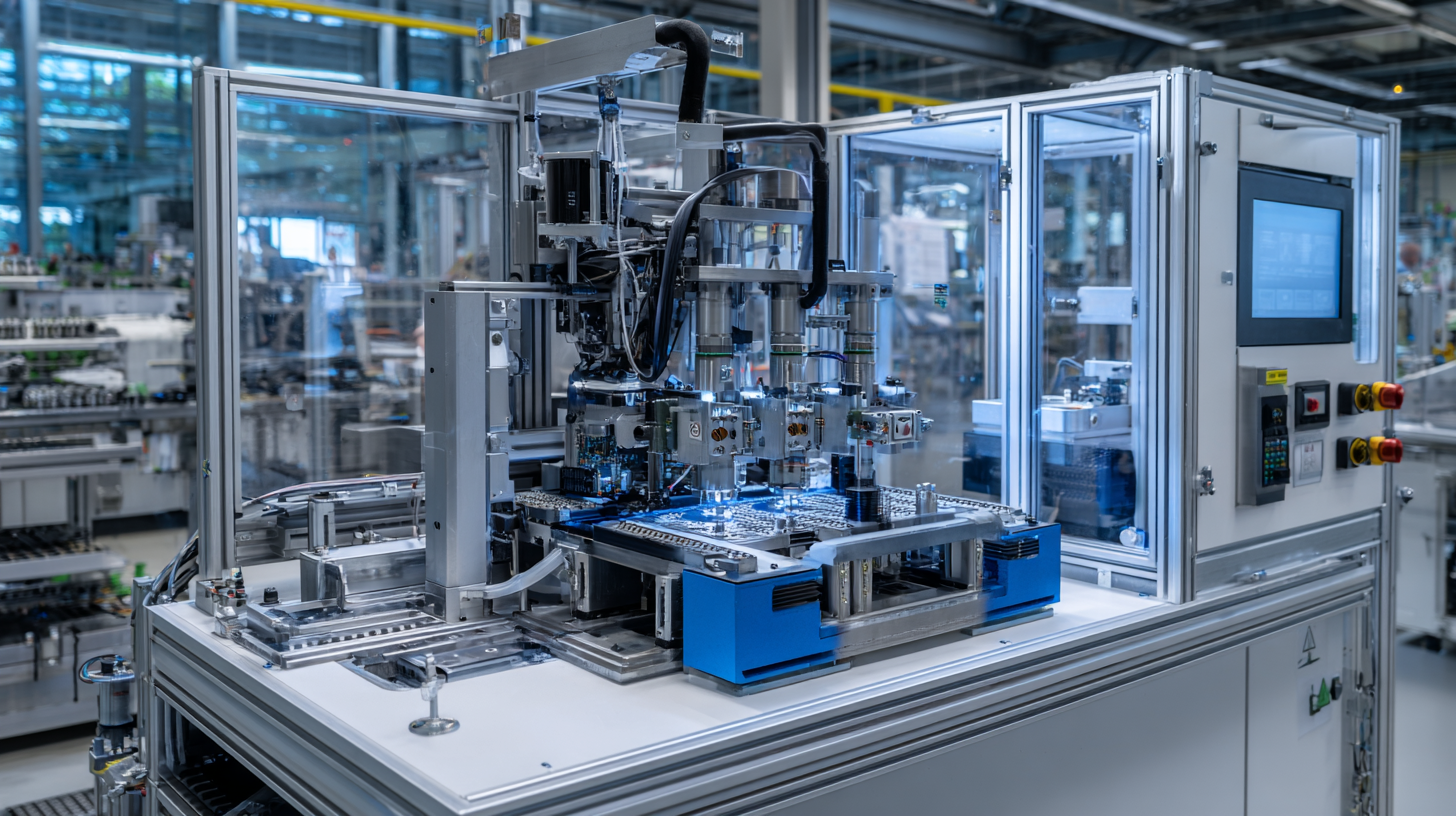

| Tabless Architecture | A design that eliminates tabs, increasing efficiency. | Enhances energy density and reduces manufacturing costs. | Joint Research and Development |

| Advanced Materials | Utilization of new electrolyte and anode materials. | Improves battery longevity and safety. | Public-Private Partnerships |

| Automated Production | Integration of AI and machine learning in production. | Increases production speed and consistency. | Industry Collaboration |

| Sustainability Practices | Focus on recycling and sustainable sourcing of materials. | Reduces environmental impact and promotes circular economy. | Non-Profit Partnerships |

The transition to tabless battery technology presents both challenges and opportunities as manufacturers aim to scale production. One of the primary challenges is the need for retooling existing production lines, which often requires significant capital investment and time. The complexity of implementing new technologies, including robotic automation and advanced material handling systems, poses additional hurdles. Companies must also navigate supply chain constraints, particularly in sourcing materials that meet the specifications for tabless designs, which may differ from traditional battery architectures.

On the upside, the tabless design offers substantial advantages in efficiency and performance, promising to enhance energy density while reducing production costs over time. As manufacturers invest in research and development, there is an opportunity to innovate further, creating new processes that could streamline production and lead to higher output capacity. Moreover, the increasing demand for clean energy solutions sets the stage for growth in this sector. By addressing these challenges head-on, companies can position themselves to capitalize on the expanding market for advanced battery technologies that align with future energy needs.