Leave Your Message

In the realm of energy storage solutions, the 18650 Cylindrical Battery Pilot Line stands at the forefront of innovation, shaping the future of battery technology. This advanced manufacturing line is crucial for developing high-performance batteries that cater to the growing demands of electric vehicles, consumer electronics, and renewable energy systems. As industries innovate and pivot towards sustainable energy solutions, the significance of the 18650 cylindrical battery cannot be overstated. It represents an optimal blend of energy density, efficiency, and safety, making it a preferred choice for various applications. This outline explores the transformative technologies and state-of-the-art processes employed within the 18650 Cylindrical Battery Pilot Line, highlighting how these advancements are paving the way for next-generation battery production and addressing the complexities of evolving market needs.

The production of 18650 cylindrical batteries is on the brink of significant transformation, driven by innovative manufacturing techniques that promise to enhance efficiency and sustainability. Recent advancements highlight the integration of locally sourced critical minerals, which is pivotal in refining battery production processes and reducing reliance on foreign supply chains. Companies are leveraging state-of-the-art technology to produce Lithium Iron Phosphate (LFP) cells, marking a crucial step towards establishing a robust North American battery ecosystem.

Emerging players in the market showcase their commitment to high-performance manufacturing through the introduction of advanced generation cells that combine high energy density with superior power delivery. As the demand for electric vehicles escalates, addressing the challenges of scaling up production without sacrificing quality becomes imperative. Innovative manufacturing techniques not only focus on enhancing battery capabilities but also on streamlining the production process, which could set new standards in the industry and facilitate a sustainable future for battery technology.

| Innovation Area | Description | Benefits | Impact on Production |

|---|---|---|---|

| Automated Assembly | Implementation of advanced robotics in the assembly line. | Increased efficiency, reduced labor costs. | Higher throughput while minimizing human error. |

| Quality Control Sensors | Integration of AI-powered sensors for real-time quality monitoring. | Enhanced product quality and consistency. | Reduction in defective products during production. |

| Advanced Materials | Utilization of new anode and cathode materials for better performance. | Higher energy density and longer battery life. | Potential to produce more powerful batteries in a smaller form factor. |

| Modular Production Systems | Flexible production lines that can be reconfigured quickly. | Adaptable to changes in demand and product types. | Increased agility and responsiveness in the manufacturing process. |

| Sustainable Practices | Focus on recycling materials and reducing waste during production. | Lower environmental impact and compliance with regulations. | Enhances corporate responsibility and brand image. |

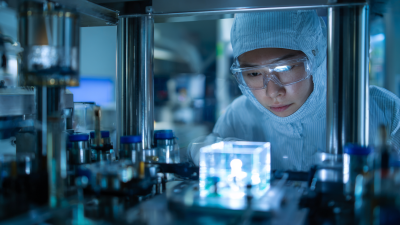

The integration of smart technologies into the pilot line operations for 18650 cylindrical batteries marks a significant advancement in manufacturing efficiency and product quality. By employing automation and advanced data analytics, manufacturers can monitor production processes in real-time, allowing for immediate adjustments that enhance yield rates. Smart sensors embedded throughout the production line collect critical data on temperature, pressure, and chemical properties, enabling predictive maintenance and reducing downtime significantly.

Furthermore, the incorporation of artificial intelligence (AI) into the pilot line operations facilitates smarter decision-making. Machine learning algorithms can analyze historical production data to identify patterns and optimize workflows, resulting in heightened productivity and reduced waste. Additionally, augmented reality (AR) tools can assist technicians in troubleshooting and maintenance tasks, ensuring that any operational challenges are promptly addressed. As these smart technologies continue to evolve, they promise to transform the landscape of battery manufacturing, making it more responsive and efficient while pushing the boundaries of innovation in energy storage solutions.

The advancements in battery testing and quality control protocols for

18650 cylindrical batteries are paramount as the demand for

energy storage solutions continues to surge. According to a report by the International Energy Agency (IEA),

the global battery market is expected to reach $150 billion by 2025, necessitating stringent quality measures

to ensure safety and efficiency. Enhanced methodologies such as automated testing systems and AI-driven analytics are being integrated into

manufacturing processes, thereby improving the consistency and reliability of battery performance.

Moreover, companies like Panasonic and LG Chem are leading the way in implementing

rigorous quality control standards, including advanced thermal imaging and impedance spectroscopy techniques.

These innovations enable real-time monitoring of battery cells during production, greatly reducing the risk of defects.

A recent study highlighted that the implementation of robust quality control measures can decrease failure rates

by up to 30%, thus significantly advancing the lifecycle and performance of

18650 batteries in various applications, from electric vehicles to consumer electronics.

The shift towards sustainable practices in the development of 18650 battery pilot lines is crucial as the demand for energy storage solutions grows. According to a recent report by McKinsey & Company, the global market for lithium-ion batteries, which includes the 18650 form factor, is expected to reach $100 billion by 2025. This immense growth is driving companies to innovate not just in technology but also in sustainability practices. Many organizations are now adopting closed-loop recycling systems that allow for the recovery of vital materials like lithium, cobalt, and nickel, reducing the environmental impact of battery production.

Moreover, advances in manufacturing techniques are enabling enhanced energy efficiency in pilot lines. For instance, a study by the International Energy Agency indicates that optimizing the production processes of lithium-ion batteries could decrease energy use by approximately 30% by 2030. These innovations not only contribute to lower operational costs but also lead to emissions reductions, aligning with global sustainability goals. By focusing on eco-friendly materials and energy-efficient manufacturing, the industry is paving the way for a greener future in battery technology.

The future of 18650 battery technology is poised for transformative changes, driven by advancements in materials science and manufacturing processes. As energy demands rise and the push for sustainable energy solutions intensifies, innovations in battery chemistry, such as the development of silicon anodes and high-capacity cathodes, are set to enhance the performance and longevity of 18650 cells. These advancements not only promise higher energy densities but also aim to reduce production costs, making electric vehicles and renewable energy storage more accessible.

Market potential for the 18650 cylindrical battery remains robust, particularly in the electric vehicle and consumer electronics sectors. With a growing emphasis on sustainability and energy efficiency, manufacturers are increasingly investing in research and development to produce batteries that meet stringent environmental standards. The integration of advanced recycling methods and the use of eco-friendly materials will further position 18650 batteries as a key player in the global energy landscape, aligning with the overarching goals of reducing carbon footprints and transitioning towards a circular economy.