Leave Your Message

The emergence of the 21700 Battery Pilot Line marks a significant milestone in the energy storage and battery production industry, offering a glimpse into the future of advanced battery technology. As the demand for higher energy density and enhanced performance grows, the 21700 format has gained prominence, catering to various applications from electric vehicles to portable electronics. This article delves into the key insights and innovations surrounding the 21700 Battery Pilot Line, highlighting its potential impact on manufacturing processes and product development.

In this exploration, we will discuss the technological advancements that facilitate the efficient production of 21700 batteries, aiming to streamline operations while ensuring quality and sustainability. The Pilot Line serves as a crucial testing ground for new manufacturing techniques, enabling researchers and engineers to identify best practices and optimize production parameters. Furthermore, we will examine the implications of these innovations on the broader battery ecosystem, including their role in meeting global energy demands and supporting the transition to greener alternatives.

By shedding light on the intricacies of the 21700 Battery Pilot Line, this article aims to provide valuable insights into the future trajectory of battery technology and its significance in shaping the energy landscape.

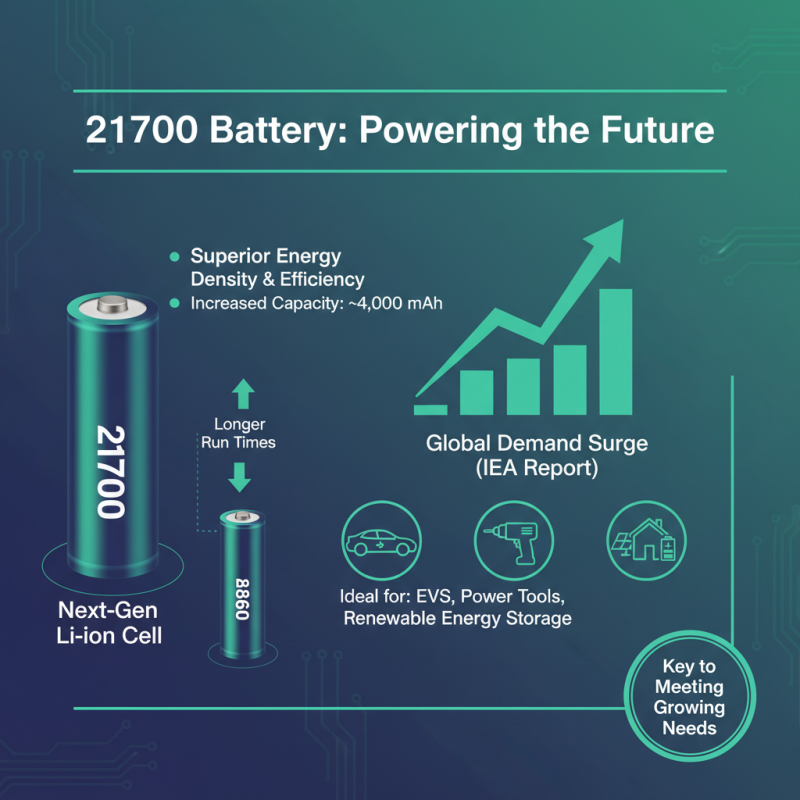

The 21700 battery has garnered significant attention in recent years due to its superior energy density and efficiency compared to its predecessors, such as the 18650 battery. With an increased capacity typically around 4,000 mAh, the 21700 battery can provide longer run times for various applications, making it an ideal choice for electric vehicles (EVs), portable power tools, and renewable energy storage systems. According to a report by the International Energy Agency (IEA), the global demand for lithium-ion batteries is projected to surge, especially in the EV sector, highlighting the importance of advanced cell formats like the 21700 in meeting these growing needs.

Additionally, the 21700 battery's structural design allows for better thermal management and enhanced safety features. A study from BloombergNEF indicates that the adoption of larger cells, including the 21700 format, not only reduces manufacturing costs but also facilitates higher energy outputs essential for high-performance applications. As industries pivot toward electrification, understanding the innovations surrounding the 21700 battery becomes crucial for stakeholders aiming to leverage its advantages in a rapidly evolving marketplace. As a result, investments in research and development of 21700 battery technology are crucial to maximize its potential in future energy solutions.

The pilot line plays a crucial role in battery manufacturing, particularly for advanced technologies like the 21700 battery. It serves as a testing ground for innovations before they are scaled up for mass production. By utilizing pilot lines, manufacturers can evaluate processes, refine designs, and identify potential issues in a controlled environment. This approach not only enhances product quality but also accelerates the development timeline, ensuring that cutting-edge solutions reach the market efficiently.

Tips for maximizing the benefits of pilot lines include focusing on modularity in design, which allows for easy adjustments and improvements based on testing outcomes. Additionally, involving cross-disciplinary teams can foster innovative solutions by integrating diverse perspectives and expertise. Regular feedback loops are also essential; they enable teams to respond quickly to findings and adapt processes to meet evolving challenges in battery technology.

Emphasizing the significance of pilot lines in battery production underscores their role in driving sustainability and efficiency. As the global demand for high-performance batteries continues to grow, establishing robust pilot lines becomes imperative for companies looking to stay competitive. By prioritizing research and development in these areas, manufacturers can not only improve their products but also contribute to the larger goal of advancing battery technology for various applications.

The 21700 battery has emerged as a game-changer in the energy storage landscape, thanks in large part to

innovative production technologies. These advancements are enhancing both the efficiency and output of battery manufacturing processes.

Recent industry reports project that the demand for 21700 batteries, particularly in electric vehicles (EVs) and renewable energy storage systems, will grow significantly, with a

forecasted annual growth rate of over 20% through 2026. This surge is driven by the need for higher energy densities and longer lifespan batteries.

Key innovations in 21700 battery production include the integration of advanced robotics and automation technologies,

which streamline assembly lines and reduce production times. For example, automated cell assembly can increase output by 30%, cutting costs

and minimizing human error. Additionally, the adoption of AI-driven quality control systems has revolutionized how defects are detected, ensuring a higher level of reliability and safety in final products.

Tips: When considering battery technologies for new projects, focus on the specifications of the battery type that best fits your needs.

High-capacity and fast-charging options like the 21700 cells are often optimal for applications requiring sustained power. Keeping abreast of the latest innovations can also lead

to improved sustainability practices in your production processes, ultimately benefiting not just your bottom line but also the environment.

The trials conducted at the 21700 battery pilot line have unveiled critical insights into the production and performance enhancements of advanced battery technologies.

These trials focus on optimizing the manufacturing processes, aiming to increase efficiency and reduce waste. By analyzing various parameters, engineers discovered that slight adjustments in temperature control and material handling significantly impact the consistency and quality of the batteries produced. This data is pivotal for scaling up production while maintaining high standards.

Moreover, the pilot line trials emphasize innovative approaches to battery design.

Enhanced cell architecture and improved electrolyte compositions are among the innovations being explored. These changes promise not only to enhance energy density but also to improve the lifespan and safety of the batteries. The combination of rich data collection and advanced technological methods is setting a new benchmark in the field of energy storage, paving the way for more sustainable and effective solutions in future energy applications.

The 21700 battery has gained significant attention in recent years due to its larger capacity and enhanced efficiency compared to its predecessors. As the demand for electric vehicles (EVs), portable electronics, and renewable energy storage continues to rise, the 21700 battery technology holds promising future trends. According to a report by IDTechEx, the global market for lithium-ion batteries is expected to grow from $47 billion in 2020 to $103 billion by 2030, reflecting an increasing reliance on advanced battery technologies.

Innovations in 21700 battery technology are being driven by improvements in energy density, thermal management, and manufacturing techniques. Advanced materials such as silicon anodes and high-nickel cathodes are playing a crucial role in enhancing capacity while reducing weight. The ongoing development of solid-state batteries presents another frontier, offering the potential for even greater energy density and safety. A study by the International Energy Agency (IEA) indicates that by 2025, solid-state battery technologies could capture up to 10% of the lithium-ion battery market, underscoring the importance of research and development in this area.

Moreover, the scalability of the 21700 battery pilot lines is crucial for meeting the increasing demand from various sectors. Recent initiatives in automation and streamlined production processes are expected to increase output efficiency and reduce costs. According to a report by McKinsey, improved operational capabilities in battery manufacturing could lower production costs by 50% by 2030. As the industry moves towards sustainability, advancements in recycling processes will also play a vital role in the circular economy, further solidifying the future viability of 21700 battery technology.