Leave Your Message

As we approach the rapidly evolving tech landscape of 2025, the significance of innovations in Battery Sleeve Labelling has become increasingly paramount. According to a recent report by MarketsandMarkets, the global battery market is projected to reach $175 billion by 2028, driven by advancements in energy storage solutions and electric vehicles. Battery Sleeve Labelling plays a crucial role in enhancing product safety, traceability, and user experience, offering essential information in a compact design. Furthermore, the introduction of smart labelling technologies, such as QR codes and NFC integration, is expected to revolutionize how consumers interact with battery products, providing real-time data and improving recycling efforts. In this dynamic environment, China's reputation for quality manufacturing positions it as a vital global partner in driving these innovations forward, ensuring that manufacturers meet both regulatory standards and consumer expectations in an increasingly digital marketplace.

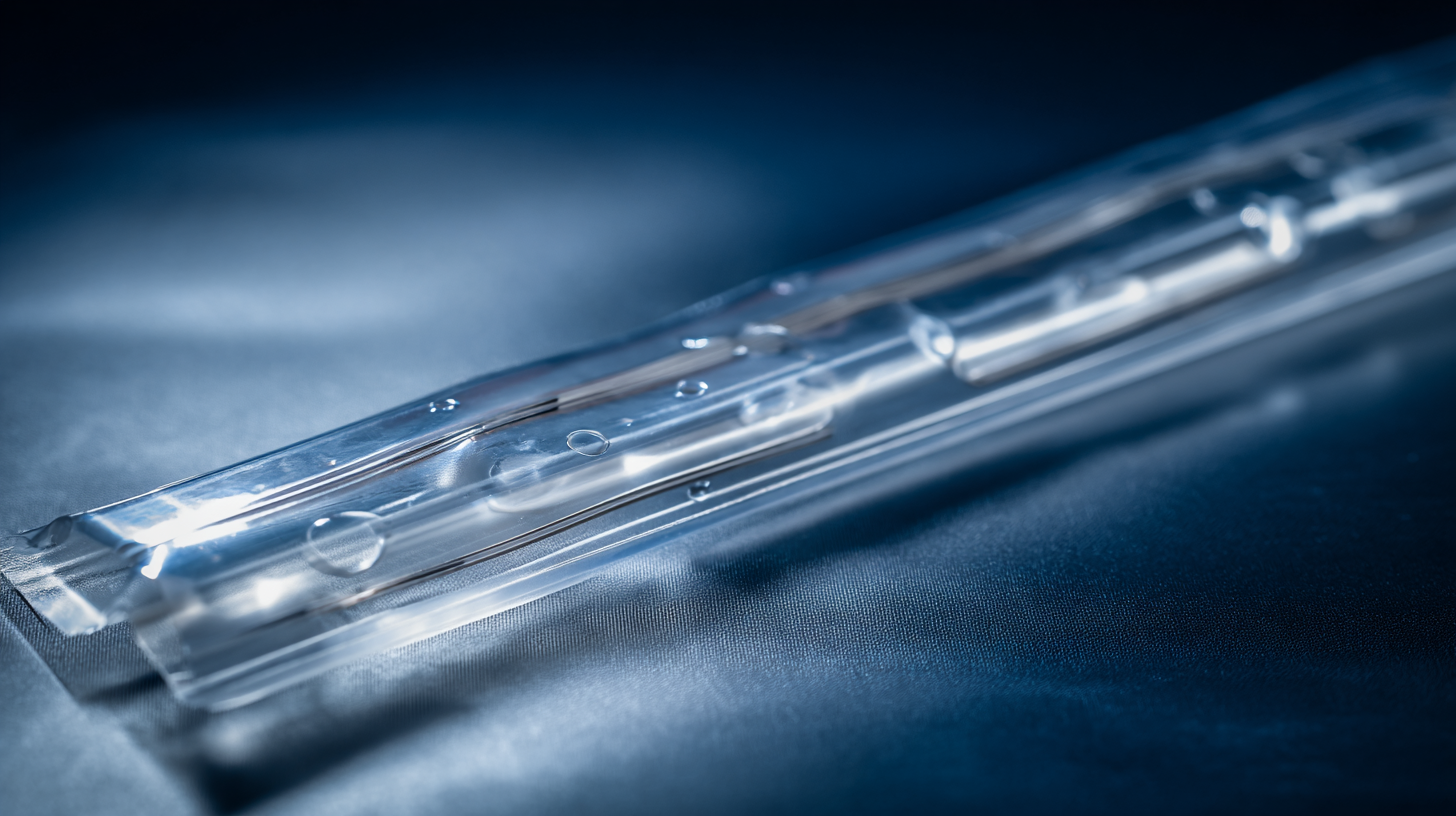

Innovative materials are set to redefine battery sleeve labeling as we approach 2025, driven by advancements in technology and sustainability. Traditional labeling methods often face challenges such as durability, visibility, and environmental impact. However, emerging innovations in materials science are paving the way for labels that are not only resilient but also eco-friendly. Biodegradable films and non-toxic inks are becoming popular, allowing manufacturers to meet stringent environmental regulations while maintaining product integrity.

Moreover, the integration of smart materials into battery sleeve labeling is revolutionizing the way information is conveyed. Labels embedded with NFC (Near Field Communication) technology and QR codes offer a dynamic way to provide end-users with crucial data. This real-time information access enhances user experience and ensures safety compliance, particularly in the rapidly evolving battery market. As manufacturers explore these innovative materials, the future of battery sleeve labeling looks promising, combining functionality with sustainability to address the demands of a tech-savvy consumer base.

| Innovation Type | Material Used | Key Feature | Environmental Impact | Expected Adoption Rate by 2025 |

|---|---|---|---|---|

| QR Code Integration | Recyclable Paper | Enhanced Traceability | Low carbon footprint | 75% |

| Smart Labels | Plastic Composite | Real-time Monitoring | Moderate; Potential for recycling | 60% |

| Biodegradable Labels | Plant-Based Materials | Eco-friendly Disposal | Minimal; fully compostable | 50% |

| Dynamic Color Change Labels | Thermochromic Materials | Temperature Indication | Low; non-toxic materials | 40% |

| Transparent Sleeves | Polyethylene | Visibility of Labeling | Moderate; recyclable | 55% |

As the battery industry evolves rapidly, so too does the need for effective labeling solutions that can cater to diverse battery types. A comparative analysis of these labeling technologies reveals significant differences in functionality and compliance standards. Lithium-ion batteries, for instance, require labels that not only provide essential safety information but also adhere to stringent transportation regulations. In contrast, lead-acid batteries benefit from labels that emphasize recycling and disposal, highlighting environmental considerations that are increasingly important to consumers.

Moreover, advancements in printing technology are revolutionizing how labels are created and applied across various battery types. Digital printing methods enable high-resolution graphics and barcodes that enhance traceability, while durable materials withstand extreme conditions typical in battery applications. Additionally, the rise of smart labels incorporating QR codes presents exciting possibilities for user engagement, allowing consumers to access detailed product information and lifecycle insights with a simple scan. As industries push towards sustainability, the future will likely see an increased demand for biodegradable label materials, ensuring that battery sleeve labeling not only meets current needs but also aligns with eco-friendly practices.

As the demand for batteries continues to rise in various sectors, regulatory standards are increasingly dictating the approach to battery sleeve labeling. Notably, the International Electrotechnical Commission (IEC) has set forth guidelines that aim to enhance safety and recyclability, with expectations that over 70% of battery manufacturers will adopt these standards by 2025. Innovations in labeling are pivoting towards clearer, more informative designs that not only comply with regulations but also streamline the recycling process.

Tips for manufacturers include investing in sustainable materials for sleeves and labels that can withstand the rigors of disposal processes. Additionally, utilizing QR codes can provide consumers easy access to crucial information regarding safe usage and recycling practices, making compliance effortless and improving overall user experience.

Moreover, the integration of digital technologies in marking, such as inkjet printing, offers flexibility and precision, enabling real-time updates to information as regulations evolve. As the landscape advances, staying ahead of regulatory shifts is paramount, prompting manufacturers to continuously adapt their labeling innovations in alignment with both regulatory standards and consumer expectations.

In the fast-evolving battery manufacturing sector, technological advancements are redefining efficiency in battery labelling processes. According to recent data from the International Energy Agency (IEA), the global demand for advanced battery technologies is projected to reach 2.3 TWh by 2025, necessitating optimized production techniques. This surge in demand puts pressure on manufacturers to streamline operations, making efficient labelling systems crucial for compliance and traceability. Innovations such as automated labelling machines and real-time data integration are pivotal in enhancing production speed and accuracy, allowing for quicker adaptation to market needs.

Moreover, the implementation of AI and machine learning in labelling processes is transforming operational capabilities. A report by MarketsandMarkets indicates that the global market for smart labels is expected to grow from $25 billion in 2021 to $41 billion by 2026, reflecting a compound annual growth rate (CAGR) of 10.5%. These smart labels are not only aiding in real-time inventory management but are also contributing to better recycle tracking, thus supporting sustainability. As battery manufacturers navigate the complexities of the 2025 tech landscape, the focus on innovative labelling solutions will be critical in meeting both regulatory requirements and consumer expectations.

As we approach 2025, the integration of smart technology into battery sleeve labels represents a significant leap forward in consumer awareness and product transparency. The latest innovations aim to enhance user engagement by providing vital information directly on the battery's sleeve, enabling consumers to make informed choices about their energy consumption. Reports indicate that by 2030, electric vehicle (EV) batteries could meet short-term grid storage demands, highlighting the critical role of battery technologies in the broader energy transition.

In tandem with advancements in battery management systems (BMS), which are expected to reach a market valuation of several billion dollars, the smart labelling of batteries will provide users with real-time data about performance, usage statistics, and recycling information. This shift is not merely about aesthetic improvements but also about fostering a more sustainable and informed consumer base. As the demand for battery energy storage systems continues to rise amidst grid volatility, smart labelling can enhance the appeal of consumer products while supporting the growth of renewable energy initiatives.

Recent studies suggest that the consumer durable market is evolving, with a growing emphasis on sustainability; smart technology embedded within battery labels aligns perfectly with this shift, giving manufacturers a competitive edge in an increasingly eco-conscious market. These developments outline a future where consumers are not only aware of their energy sources but are also empowered to make choices that contribute to a cleaner, more efficient world.