Leave Your Message

The rapid growth of the electric vehicle market and the increasing demand for renewable energy sources have propelled the need for efficient battery production systems. According to a recent report by McKinsey & Company, the global battery market is projected to reach $260 billion by 2025, underscoring the critical role of advanced manufacturing technologies.

The rapid growth of the electric vehicle market and the increasing demand for renewable energy sources have propelled the need for efficient battery production systems. According to a recent report by McKinsey & Company, the global battery market is projected to reach $260 billion by 2025, underscoring the critical role of advanced manufacturing technologies.

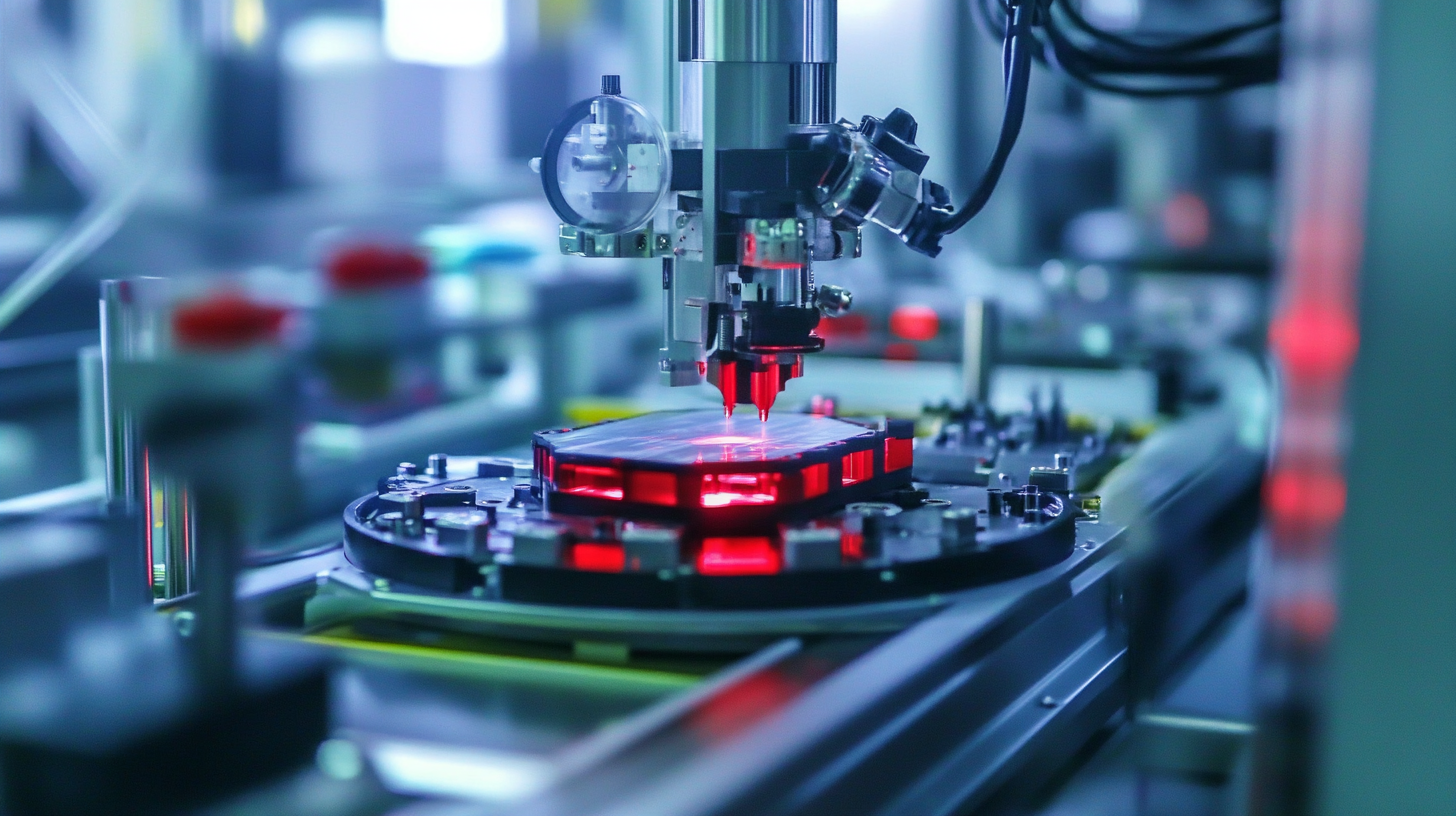

Among these technologies, the Lab-Scale Battery Packaging Machine is vital for creating prototypes and small series in a controlled environment, allowing for iterative testing and optimization. However, many manufacturers encounter common pitfalls in the implementation of these machines, which can lead to inefficiencies and increased costs. By taking a data-driven approach to identify and address these challenges, manufacturers can enhance their operations significantly, ensuring that their packaging processes align with industry standards and innovation demands.

In the rapidly evolving field of energy storage, lab-scale battery packaging processes face numerous challenges that can hinder efficiency and scalability. One key issue is the lack of standardized protocols during packaging, which leads to inconsistencies in battery performance and quality. Without a uniform approach, variations in materials and techniques can result in unpredictable outcomes, ultimately affecting the reliability of battery systems.

Another significant challenge is the integration of data analytics into packaging solutions. Many labs operate with traditional methods that do not leverage real-time data to monitor and optimize packaging processes. By adopting a data-driven perspective, labs can identify bottlenecks and areas for improvement, enabling them to make informed decisions that enhance productivity. This technological transition not only ensures higher quality standards but also paves the way for innovations that could redefine battery packaging methodologies. Addressing these challenges with a focus on data can lead to more robust and reliable energy storage solutions.

In the ever-evolving field of battery technology, the efficiency of lab-scale battery packaging machines is crucial for optimizing production processes. By leveraging advanced data analytics, manufacturers can gain insights into their machinery operations, revealing patterns that may not be immediately visible. This approach not only enhances the understanding of machine performance but also uncovers inefficiencies that can be addressed directly, leading to improved throughput and reduced costs.

Data-driven strategies allow for real-time monitoring of key performance indicators, such as cycle times and error rates. By collecting and analyzing operational data, businesses can identify common pitfalls, enabling them to implement targeted interventions. For instance, predictive analytics can forecast potential machine failures, allowing for preemptive maintenance that minimizes downtime. Furthermore, these insights can be utilized to refine the packaging process itself, optimizing parameters such as speed and temperature to ensure consistent product quality.

Incorporating a culture of data-driven decision-making into packaging operations fosters an environment of continuous improvement. As teams become adept at using analytics tools, the overall efficiency of lab-scale battery packaging machines can be significantly enhanced, paving the way for innovations and advancements in battery production technology. This shift not only boosts productivity but also supports sustainability goals by optimizing resource use and reducing waste.

When it comes to lab-scale battery packaging machines, many misconceptions cloud the understanding of their actual capabilities. One common belief is that these machines are only suitable for large-scale production, leading researchers and engineers to overlook their potential in small-batch scenarios. In reality, lab-scale machines are designed for versatility, allowing for rapid prototyping and iterative testing. They can effectively handle various battery formats and chemistries, providing essential data for scaling up production later.

Another misconception is regarding the complexity of integrating these machines into existing workflows. Some practitioners fear that introducing lab-scale packaging machines will disrupt established processes. However, modern designs prioritize user-friendliness and adaptability, often allowing seamless integration with other laboratory equipment. By leveraging real-time data and automation, these machines can enhance efficiency, reduce operational bottlenecks, and ultimately improve the research and development cycle. It's crucial for teams to recognize these capabilities to fully harness the potential of lab-scale battery packaging technology.

| Pitfall | Description | Impact on Efficiency | Frequency (%) | Mitigation Strategies |

|---|---|---|---|---|

| Inadequate sealing | Failure to properly seal battery cells can lead to leaks. | High | 25 | Implement rigorous quality checks and use advanced sealing techniques. |

| Incorrect material use | Using wrong materials that do not withstand battery chemicals. | Medium | 15 | Conduct thorough material compatibility tests. |

| Insufficient automation | Lack of automated processes can increase human error. | High | 30 | Invest in automated line integration. |

| Poor training | Operator errors due to inadequate training on machines. | Medium | 20 | Enhance training programs and regular refreshers. |

| Neglecting maintenance | Failure to perform regular maintenance can lead to machine failure. | Very High | 40 | Establish a strict maintenance schedule. |

In the rapidly evolving landscape of battery technology, optimizing lab-scale battery packaging machines is crucial for ensuring high efficiency and performance. Recent industry reports indicate that up to 30% of production time can be lost due to inefficiencies in packaging processes. To combat this, innovative solutions leveraging data-driven insights are emerging. By employing advanced analytics and real-time monitoring, manufacturers can significantly reduce downtime and enhance workflow efficiency, leading to better output and cost savings in the lab environment.

**Tip**: Regularly analyze performance metrics to identify bottlenecks in the packaging process. Implementing predictive maintenance strategies can avert potential failures and maintain equipment in peak condition.

Moreover, adopting modular packaging systems can facilitate flexibility and scalability. Research from the Battery Packaging Association indicates that companies using modular designs report a 20% increase in production adaptability. This approach not only allows for faster changes between packaging types but also supports the increasing demand for diverse battery configurations.

**Tip**: Integrate a feedback loop in your packaging process to continuously improve and customize operations based on production data, ensuring your facility can meet the evolving market demands.

The landscape of battery packaging technology is evolving rapidly, driven by advancements in materials and automation. Future trends are set to focus on integrating smart technologies into machine design, enabling real-time monitoring and analytics. This data-driven approach not only enhances the efficiency of packaging processes but also significantly minimizes waste, thereby promoting sustainability in battery production. As manufacturers aim for higher precision and faster turnaround times, the incorporation of artificial intelligence and machine learning will play a critical role in optimizing performance.

Moreover, the move towards more modular machine designs will facilitate greater flexibility in production lines. By adopting a design architecture that allows for easy upgrades and component swapping, manufacturers can swiftly adapt to changes in battery technology and market demands. This ensures that the machinery remains relevant and efficient, even as new battery chemistries emerge. Ultimately, the future of battery packaging machines will be characterized by a harmonious blend of innovative technology, sustainability, and adaptability, paving the way for the next generation of energy storage solutions.