Leave Your Message

In the rapidly evolving world of battery manufacturing, the significance of selecting the right equipment cannot be understated, particularly when it comes to a Lab-Scale Battery Packaging Machine. As production demands increase and market competition intensifies, manufacturers are tasked with not only enhancing efficiency but also ensuring the precision and quality of their products. Understanding the various features and capabilities of lab-scale packaging machines is essential for optimizing production processes while accommodating the specific needs of different battery types. Whether you are a startup or an established company aiming to innovate, navigating through the myriad of options available in the market can be overwhelming. This blog will provide essential insights into the key factors to consider when choosing a Lab-Scale Battery Packaging Machine, empowering you to make informed decisions that align with your production goals and ensure the successful scaling of your operations.

In the rapidly evolving landscape of battery production, understanding the role of packaging machines has become increasingly crucial. As the global market for lithium-ion batteries expands, manufacturers are faced with not only the challenge of producing efficient batteries but also the necessity of ensuring these delicate components are protected during storage and transportation. Proper protective packaging is vital, particularly for sensitive products like batteries that can be subject to environmental stresses. Innovations in packaging technology can significantly impact the battery lifecycle, from production directly through to end-of-life management.

Additionally, advancements in packaging systems, particularly in the context of automation and pneumatics, are setting new standards for efficiency and safety in the industry. As competition heightens and sustainability becomes a priority for consumers, manufacturers who adopt advanced packaging solutions will not only enhance the protection of their products but also streamline their operations. This shift towards improved packaging methodologies reflects broader trends within the semiconductor and battery sectors, where lightweight and resilient solutions are becoming the norm. Embracing these advancements is essential for battery producers aiming to meet the ever-increasing demands of the market while ensuring product integrity and environmental responsibility.

This bar chart illustrates the efficiency of different battery packaging machines in terms of production capacity and speed. Understanding these metrics is essential for selecting the right machine to meet production needs.

When selecting a lab scale battery packaging machine, certain key features play a critical role in meeting production demands effectively. First and foremost is the machine's speed and efficiency. According to recent industry reports, the average production speed for lab-scale machines has increased by around 25% over the past five years. This surge means that choosing a machine with a higher throughput can significantly enhance your operational workflow, making it essential to evaluate the machine's capabilities in context to your specific requirements.

Another crucial aspect is the versatility of the packaging options. With the growing trend towards customization in battery manufacturing, machines that can accommodate multiple packaging formats—such as pouches, trays, and cartons—are in high demand. A comprehensive report from the Packaging Machinery Manufacturers Institute indicates that 68% of manufacturers are now prioritizing flexibility in their machinery to cater to an evolving market. Additionally, scalability is vital; the chosen machine should not only meet current production needs but also allow for easy upgrades as your operations expand. The right lab scale battery packaging machine needs to balance these features to enhance both efficiency and adaptability in the fast-evolving battery industry.

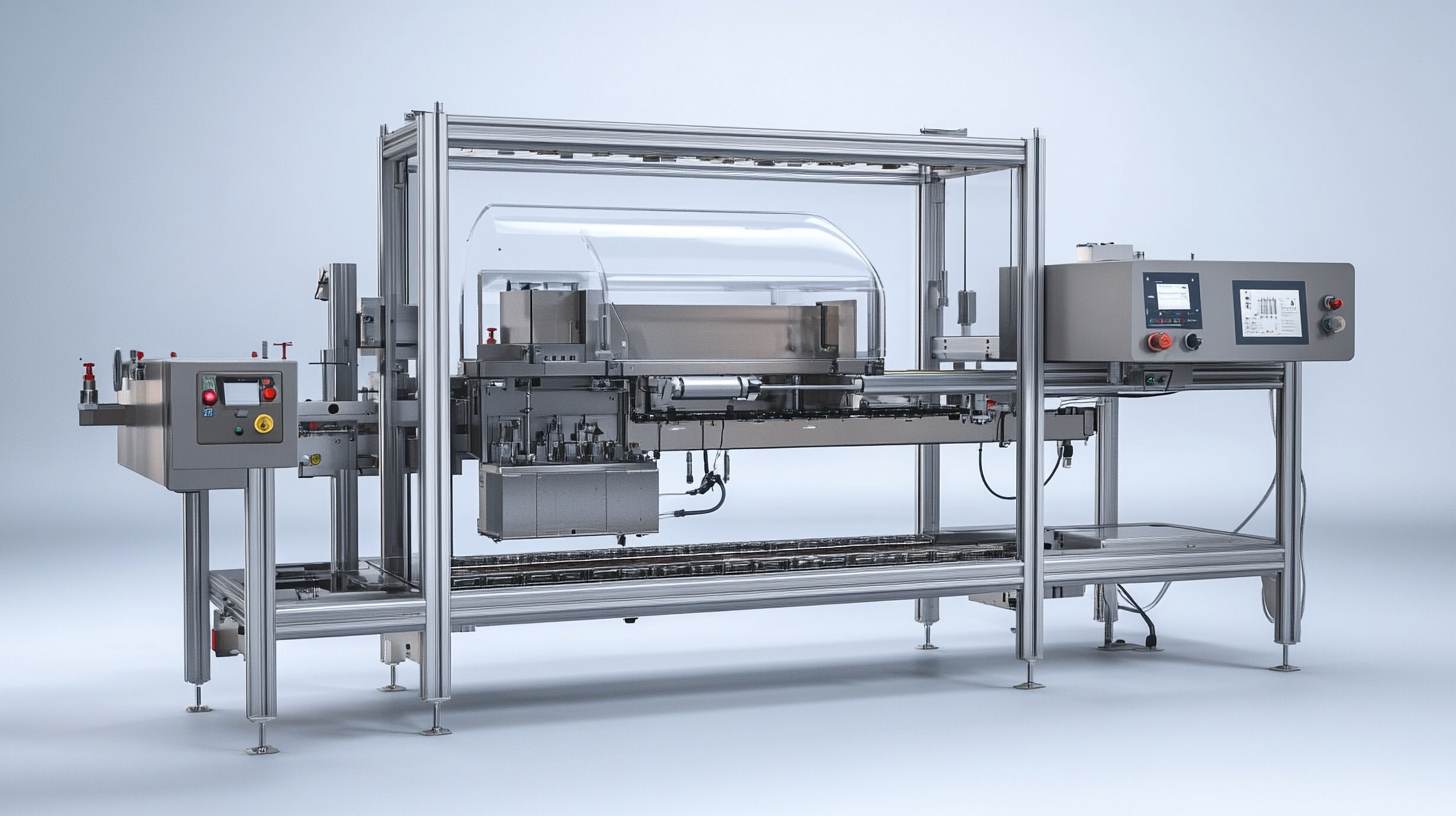

When selecting a battery packaging machine for your production line, it is crucial to understand the various types available and their efficiency in handling different battery technologies. Battery packaging machines come in several configurations, each designed to meet specific requirements of battery production. For instance, automatic machines provide high throughput and precision, essential for mass production, while semi-automatic options may be suitable for smaller batch sizes, offering flexibility at a lower investment cost.

In comparing these machines, consider factors such as the compatibility with different battery chemistries, including lithium-ion, solid-state, and newer liquid electrolyte technologies. Each technology presents unique challenges in packaging, like varying sizes and thermal management needs. Additionally, the machine’s capabilities to ensure a secure and efficient packing process can significantly influence the overall quality and reliability of the battery produced. Selecting the right packaging machine not only enhances operational efficiency but also supports the sustainability goals of your production facility by minimizing waste and ensuring product longevity.

When it comes to selecting a lab scale battery packaging machine, one of the critical considerations is the balance between cost and performance. According to a report by Research and Markets, the global battery packaging market is expected to grow at a CAGR of 9.1% from 2021 to 2026, highlighting the increasing demand for efficient and reliable packaging solutions. This growth underscores the necessity of investing in machines that not only fit budget constraints but also enhance productivity and quality.

Evaluating performance metrics such as speed, precision, and compatibility with various battery sizes is essential. A high-performance machine, although initially more expensive, can reduce long-term operational costs due to lower maintenance and higher throughput. Industry data suggests that manufacturers utilizing advanced packaging technology can see a 25% increase in production efficiency, making the upfront investment worthwhile. Thus, businesses must conduct thorough cost-benefit analyses to ensure that their choice aligns with their production goals while offering longevity and efficiency in their packaging processes.

When investing in a lab scale battery packaging machine, understanding the importance of maintenance is crucial for ensuring the longevity and efficiency of your equipment. Regular maintenance not only helps in identifying potential issues before they escalate but also optimizes the performance of the machine, which is essential for consistent production output. Simple practices such as routine cleaning, lubrication of moving parts, and checking for wear and tear can significantly extend the lifespan of your packaging equipment.

Moreover, keeping an eye on the calibration of the machine can prevent inaccuracies that might lead to increased waste and downtime. It is advisable to establish a detailed maintenance schedule and involve your team in periodic checks. Documentation of maintenance activities can help in identifying patterns, allowing for more proactive management of the machine’s needs. Implementing these maintenance tips will not only safeguard your investment but also ensure that your production meets the highest standards of efficiency and quality.

| Criteria | Details |

|---|---|

| Machine Type | Semi-Automatic, Fully Automatic, or Manual |

| Production Capacity | Units per Hour |

| Size and Weight | Dimensions for Space Considerations |

| Material Compatibility | Types of Films and Materials Used |

| Ease of Use | User-Friendly Interfaces |

| Maintenance Frequency | Daily, Weekly, Monthly Checks |

| Warranty and Support | Coverage Duration and Service Availability |

| Cost Efficiency | Initial Cost vs. Long-term Benefits |