Leave Your Message

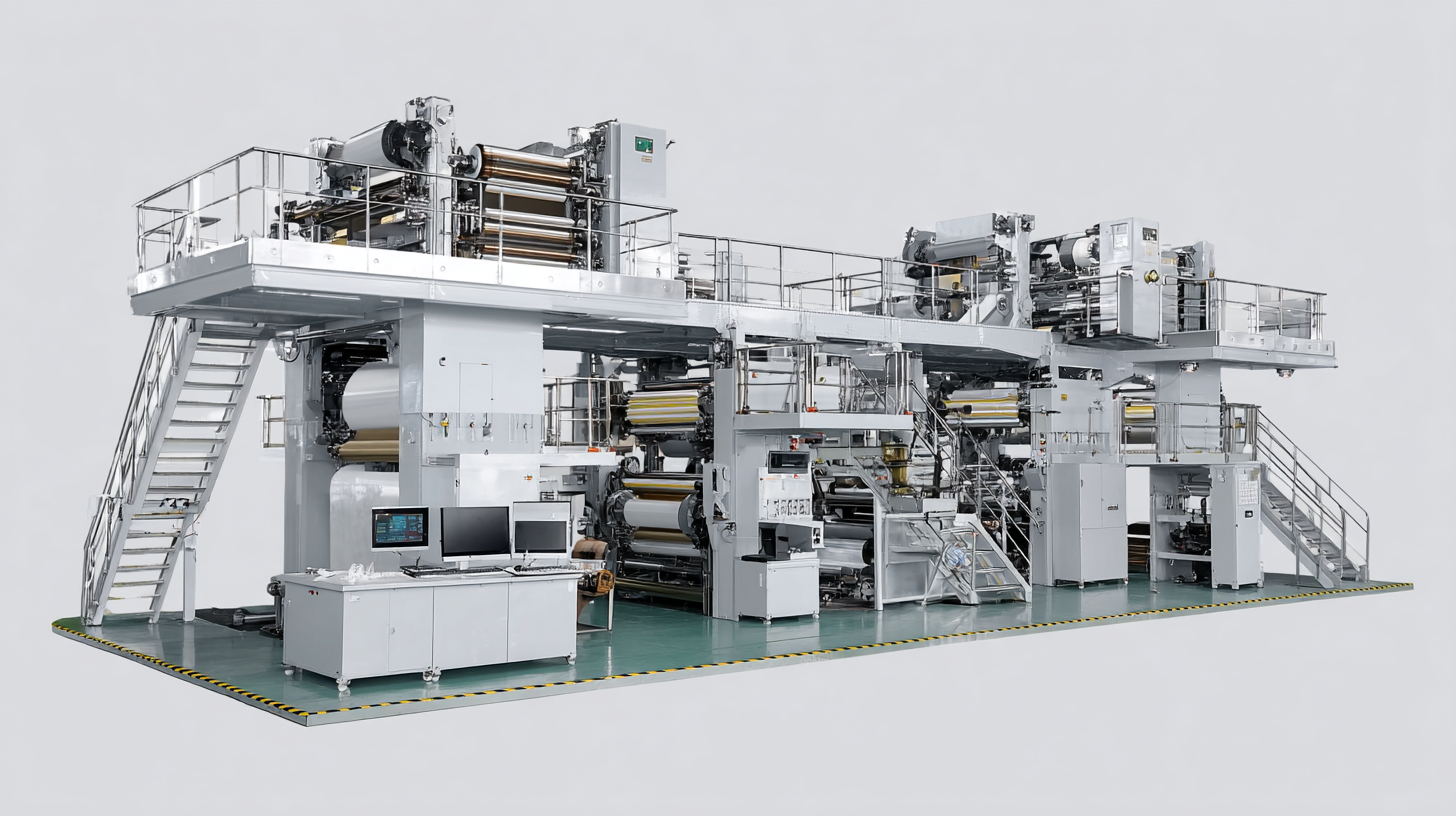

In the fast-paced world of manufacturing, selecting the right equipment can significantly impact productivity and efficiency. Among the essential machinery, the Integrated Calendering and Slitting Machine stands out as a versatile solution for transforming raw materials into finished products. This ultimate guide will walk you through the key considerations when choosing the best Integrated Calendering and Slitting Machine for your factory.

From understanding the specific processes involved to evaluating the features that enhance performance, this guide aims to equip you with the knowledge necessary to make an informed decision. Whether you're a seasoned manufacturer or just starting out, understanding how to select the right machine can streamline operations and boost output, setting your factory up for success in a competitive market.

When selecting the best integrated calendering and slitting machine for your factory, it’s crucial to understand the key features that can enhance production efficiency and product quality. Integrated machines are designed to streamline processes, combining both calendering and slitting capabilities, which can significantly reduce operational costs and improve throughput. Key features to consider include automation level, size variability, and material compatibility. Advanced models often incorporate smart technology that allows for real-time monitoring and adjustments, ensuring optimal performance.

Moreover, the global market for battery production machines, which is projected to grow from $13.26 billion in 2024 to $37.59 billion by 2034, highlights the increasing importance of responsive and versatile machinery in manufacturing environments. This growth signals a heightened demand for state-of-the-art integrated machines that can meet the evolving needs of industries, particularly in battery production. By investing in high-quality integrated calendering and slitting machines, manufacturers can position themselves to capitalize on market trends and ensure they remain competitive in the ever-expanding landscape of production technologies.

When selecting an integrated calendaring and slitting machine for your factory, it is crucial to evaluate your specific requirements. Understanding the nature of your production process is the first step. Consider factors such as the materials you will be working with, the desired thickness, and the overall texture of the final product. These elements will significantly influence the type of machine you choose, as different models are designed to accommodate various materials and production speeds.

Another vital aspect to assess is your factory’s operational capacity and workflow. Analyze your current setup and determine how much space you can allocate for new machinery. It's essential to ensure that the chosen machine integrates seamlessly with your existing equipment to optimize efficiency. Additionally, consider the volume of production you require; some machines are better suited for high-output environments, while others may be more efficient for smaller, custom runs. Taking these factors into account will lead you to make an informed decision tailored to your factory’s unique needs.

| Parameter | Description | Importance Level | Recommended Options |

|---|---|---|---|

| Production Capacity | The volume of materials the machine can handle per hour. | High | 500-1000 kg/h |

| Material Compatibility | Types of materials the machine can process effectively. | Medium | Polymer, Paper, Foils |

| Precision | Accuracy of cutting and calendering dimensions. | High | ±0.1 mm |

| Power Consumption | Energy used by the machine in operation. | Medium | 50-100 kW |

| Ease of Maintenance | How easy it is to perform routine maintenance. | High | Modular design for easy access |

| Automation Level | The degree to which the machine operates independently. | Medium | Semi-automated options available |

When it comes to selecting the best integrated calendaring and slitting machine for your factory, comparing different brands and models is crucial. These machines come with varying features and specifications that can greatly impact your production efficiency. Before making a decision, understand the specific needs of your manufacturing process. Consider the width and thickness of the materials you handle, as some machines are better suited for lighter materials while others can handle heavier loads.

Tip: Always look for machines that offer customizable features. Some brands provide options for adjusting temperature, pressure, and speed settings, which can significantly enhance the quality of your final product. Additionally, check for compatibility with the types of materials you plan to work with, as this will play a significant role in the machine's overall effectiveness.

Another important factor to consider is after-sales service and support. Different brands may offer various levels of customer service, warranty, and maintenance options. Ensure that the manufacturer you choose has a good reputation for customer support, as this can be invaluable when it comes to troubleshooting and repairs.

Tip: Research user reviews and testimonials to gauge the reliability of the brands you are considering. Real-world feedback can provide insights into the performance and durability of the machines, helping you make an informed decision for your factory’s needs.

When evaluating the cost-effectiveness of integrated machinery solutions such as calendering and slitting machines, it’s crucial to analyze the long-term return on investment (ROI) compared to standalone equipment. According to industry reports, the global computer-aided engineering (CAE) market is projected to grow from $7,072.3 million in 2025 to $12,993.7 million by 2033, with a compound annual growth rate (CAGR) of 7.9%. This growth highlights the increasing reliance on integrated solutions that streamline manufacturing processes while reducing operational costs.

**Tip:** When choosing a machine, consider not only the initial purchase price but also the operational costs and potential savings over time. Integrated systems often provide enhanced efficiency, which can translate into significant reductions in labor and energy costs.

Additionally, the adoption of technologies like generative AI in manufacturing is driving innovation but poses varying costs based on deployment models. For instance, implementing custom generative AI solutions can range from a few hundred to $190,000 monthly, reflecting the diverse investment required for advanced capabilities.

**Tip:** Carefully assess your factory's specific needs and budget constraints to determine the most appropriate technology and service model. Engaging with an expert can help in tailoring solutions that maximize productivity while minimizing costs.

When investing in an integrated calendaring and slitting machine, maintenance and support are crucial factors to consider. Regular maintenance not only prolongs the life of your equipment but also ensures optimal performance. It's essential to establish a maintenance schedule that includes routine inspections and necessary adjustments to keep your machine running smoothly.

**Tip:** Collaborate closely with the manufacturer to understand their recommended maintenance practices and incorporate them into your operational procedures. This will help minimize downtime and the risk of unexpected malfunctions.

Additionally, consider the availability of support services from the manufacturer. Efficient customer support can make a significant difference when issues arise. Ensure that the supplier you choose offers accessible technical assistance and has a solid reputation for after-sales service.

**Tip:** Research online reviews or seek references from other businesses to gauge the reliability of the manufacturer's support services before making your purchase. This will provide peace of mind knowing that help is readily available when you need it.