Leave Your Message

In today's energy-focused world, developing a 21700 Battery Pilot Line is crucial. This battery size has gained popularity due to its efficiency and performance. However, building such a production line is not without challenges. Factors like material sourcing, manufacturing processes, and quality control play significant roles in success.

Efficiently creating a 21700 Battery Pilot Line requires flexible planning. Facilities need the right equipment and layout for optimal workflow. It's easy to overlook minor details, which may lead to inefficiencies. For instance, improper alignment in assembly can slow down production. Regular assessments are necessary to identify such issues.

Additionally, a skilled workforce is essential. Training employees in battery technology and safety is vital. However, there's a risk of inconsistencies in skill levels. This may affect the overall quality of the product. Reflection on training methods can lead to improvements. Thus, building a 21700 Battery Pilot Line is a task that demands careful consideration and continuous learning.

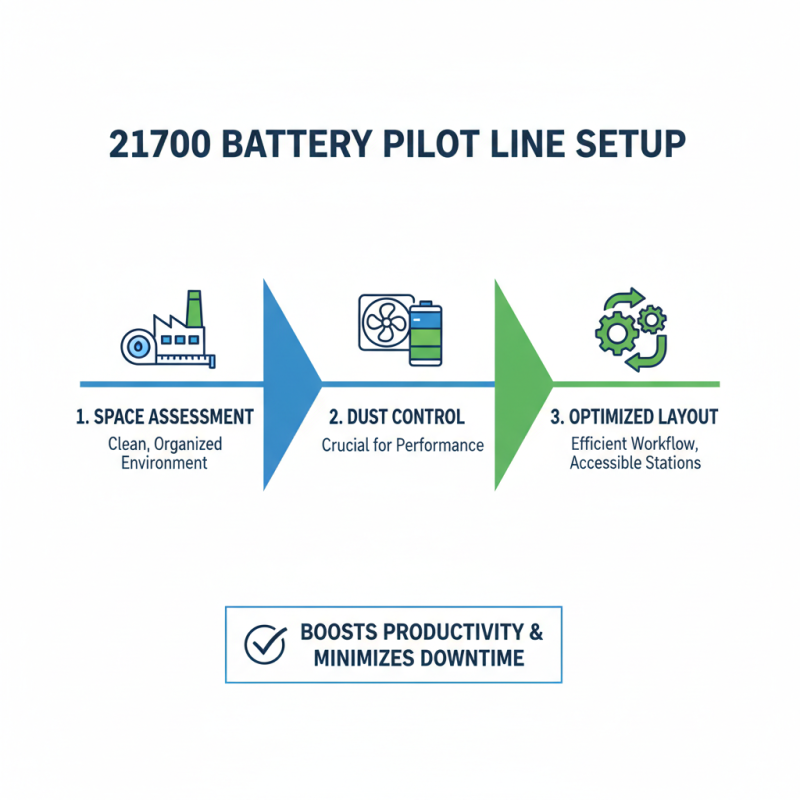

Setting up a 21700 battery pilot line requires careful planning. Start by assessing space requirements. A clean, well-organized environment is crucial. Dust can affect battery performance. Ensure the layout promotes efficient workflow. Each station should be conveniently accessible. This setup boosts productivity and minimizes downtime.

Safety is paramount when designing your pilot line. Implement clear safety protocols for all operators. Regular training sessions must be held to keep everyone informed. Don't overlook equipment maintenance. Faulty machines can lead to accidents and production delays. Regular checks are essential.

Consider the importance of scalability. Plan for future expansion. Today's pilot line may need to adapt to increased demand. Often, businesses fail to account for this growth potential. Evaluate processes regularly and adjust accordingly. This flexibility will support long-term success in manufacturing. Keep an open mind to learning from mistakes. The path to efficiency is often paved with trial and error.

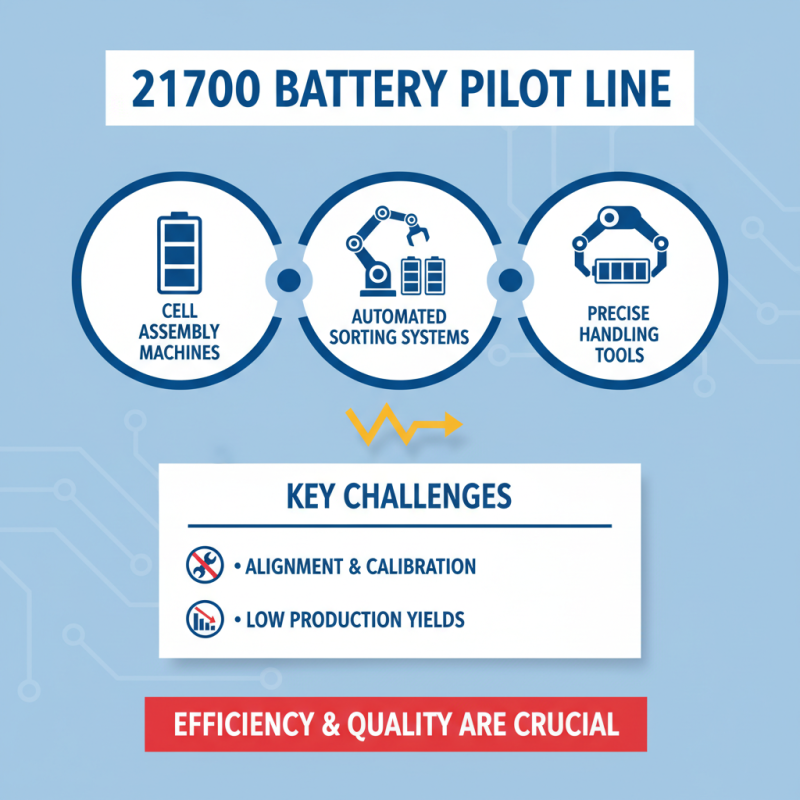

Building a 21700 battery pilot line requires specific equipment and technology. Key components include advanced battery cell assembly machines, automated sorting systems, and precise handling tools. Each piece of equipment plays a critical role in maintaining efficiency and quality. Workers often encounter challenges with alignment and calibration. This affects production yields.

Investing in battery testing stations is also essential. These stations check voltage, capacity, and internal resistance. Regular maintenance is necessary to keep them functioning well. Sometimes, testing reveals that a batch is not up to standard. This can lead to waste and require a reassessment of processes.

Proper ventilation in the manufacturing area is crucial. Battery chemicals can be volatile. Ensuring air quality is not just about comfort; it’s a safety concern. Unexpected leaks can cause significant delays and increase costs. Industrial cleaning must address these potential hazards systematically. Overall, an efficient pilot line needs to prioritize safety while refining technology and equipment. Regular feedback from operators helps identify areas that need improvement.

Establishing a 21700 battery pilot line requires careful planning. Efficiency is key in every step. Start with sourcing high-quality materials. This ensures better output and less waste. Train your staff thoroughly. Everyone should know their roles.

Tips: Keep an eye on material costs. Reducing waste in sourcing can significantly improve your bottom line.

Next, design a streamlined workflow. Each production phase should lead smoothly to the next. Think about layout. Avoid bottlenecks by arranging machines in a logical order. Utilize technology to monitor processes. Real-time data can enhance analysis and adjustments.

Tips: Regularly review equipment effectiveness. If a machine underperforms, investigate solutions or replacements.

Lastly, implement quality control at every stage. Identifying defects early helps to minimize resource loss. Workers should have the tools to report issues. Encourage open communication about what doesn’t work. Reflecting on processes often reveals areas for improvement.

This chart illustrates the daily production efficiency of a 21700 battery pilot line over a week. The data shows the number of batteries produced each day, allowing us to identify trends and areas for improvement.

Quality control is essential in the production of 21700 batteries. These batteries serve various applications, from electric vehicles to portable devices. Setting high standards ensures safety and performance. Regular inspections during the production line are crucial. Simple checks can catch defects early.

Implementing process controls is another key measure. Monitoring temperature and pressure during assembly can prevent failures. Machines need calibration, but human oversight is equally important. A skilled workforce is vital. Workers should be trained to identify flaws in materials and assembly. Their experience adds a layer of quality assurance.

Data collection is also beneficial. Tracking defect rates helps identify patterns over time. However, data can be overwhelming. Finding the right metrics to monitor is often a challenge. It's essential to remain vigilant and adapt strategies based on findings. Quality control measures should evolve with technological advancements. Production lines must be flexible to accommodate new techniques.

| Quality Control Parameter | Measurement Method | Frequency of Check | Acceptable Range | Responsibility |

|---|---|---|---|---|

| Cell Voltage | Multimeter Measurement | Every Batch | 3.0 - 4.2 V | Quality Control Team |

| Internal Resistance | AC Impedance Analyzer | Daily | Less than 30 mΩ | Engineering Team |

| Cycle Life | Cycle Testing Machine | Weekly | > 500 Cycles | R&D Team |

| Capacity | Discharge Testing | Every Batch | 2500 - 3000 mAh | Quality Control Team |

| Thermal Stability | Thermal Imaging | Monthly | < 70 °C | Safety Team |

Building a 21700 battery pilot line requires careful resource management and staffing strategies. Optimal staffing can significantly impact productivity and quality. Hiring individuals with diverse skills can foster innovation. It's crucial to assemble a team with a balance of experience and fresh perspectives. Regular training sessions can enhance skills, but they should be well-planned to minimize downtime.

Resource allocation is another critical area. Too much investment in one area can divert funds from essential components. Monitoring material usage ensures no wastage occurs. It might seem challenging, but frequent audits can highlight inefficiencies. Communication among team members can help identify discrepancies in resource management.

Reflecting on initial stages is essential. Some decisions may not yield expected results. Learning from these missteps can guide future actions. Adopting a flexible approach in staffing and resource management empowers teams to adapt swiftly. Small adjustments can lead to significant improvements, fostering a more efficient pilot line setup. Every small win matters in this journey.