Leave Your Message

As the demand for advanced battery technologies continues to surge, driven by the global shift towards renewable energy and electric vehicles, the importance of efficient packaging solutions cannot be overstated. A recent report by MarketsandMarkets projects that the global battery packaging market will reach $10.04 billion by 2025, growing at a CAGR of 8.7%. Central to this growth are innovations in Lab-Scale Battery Packaging Machines, which play a pivotal role in the research and development of new battery chemistries and formats.

These machines not only enhance the efficiency of the packaging process but also ensure quality and consistency in battery production, critical factors as manufacturers strive to meet stringent safety and performance standards. As we delve into the five best innovations in this area, it becomes clear that staying informed about these advancements is essential for industry professionals seeking to maintain a competitive edge.

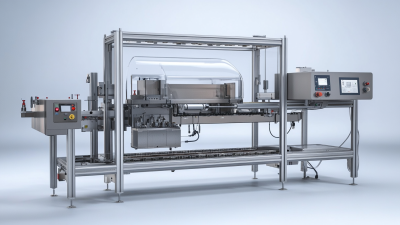

Lab-scale battery packaging machines are critical for the efficient production of lithium-ion batteries, especially as the industry moves toward more sustainable and advanced manufacturing techniques. One innovative feature to look for in these machines is their ability to optimize energy consumption, which is increasingly a concern as manufacturers seek to minimize their carbon footprint. Recent studies have shown that enhancements in manufacturing technology can yield up to a 30% reduction in energy use while maintaining throughput, making these innovations essential for aligning with global sustainability goals.

Another key feature of modern lab-scale battery packaging machines is their integration with AI and robotics. Companies are adopting automation technologies that streamline operations and enhance precision in battery assembly. Reports suggest that the implementation of intelligent systems in manufacturing processes can improve production efficiency by over 20%. Moreover, as competition intensifies, innovations in packaging technology, such as advanced materials that provide better protection against environmental impacts, are becoming standard offerings among leading suppliers in the industry. Keeping an eye on these evolving features will empower businesses to stay ahead in the rapidly evolving battery market.

| Feature | Description | Benefits | Applications |

|---|---|---|---|

| Automated Filling | Precision automated filling systems for consistent battery materials. | Increases production efficiency and reduces material waste. | Lithium-ion battery production, R&D labs. |

| Real-time Monitoring | Integrated sensors that monitor packaging parameters in real-time. | Ensures high quality and consistency of battery packs. | Quality control in battery manufacturing. |

| Modular Design | Flexible modular designs for easy upgrades and maintenance. | Reduces downtime, enhances scalability of operations. | Custom packaging solutions across different battery types. |

| Compact Footprint | Space-saving designs ideal for lab environments. | Maximizes lab space efficiency while maintaining functionality. | Laboratory testing, small-scale production. |

| User-friendly Interface | Intuitive touchscreen controls for ease of operation. | Reduces the learning curve for new operators. | Laboratory settings, educational institutions. |

The world of battery packaging is undergoing a significant transformation as automated solutions take center stage. Innovations in lab-scale battery packaging machines are streamlining processes that were once labor-intensive and time-consuming. By integrating advanced robotics and smart technology, these machines are enhancing precision and efficiency, ensuring that battery cells are packaged safely and securely.

This shift not only minimizes human error but also accelerates production timelines, responding to the growing demand for batteries in various industries, including electric vehicles and renewable energy.

Moreover, these automated solutions are not just about speed; they also offer scalability. Manufacturers can easily adjust their packaging systems to accommodate different batch sizes, ensuring adaptability in a rapidly evolving market. Features such as real-time monitoring and data analytics allow for better quality control and predictive maintenance, further optimizing the packaging process. As companies continue to seek ways to innovate and remain competitive, the integration of these state-of-the-art lab-scale battery packaging machines represents a pivotal advancement in the battery manufacturing landscape.

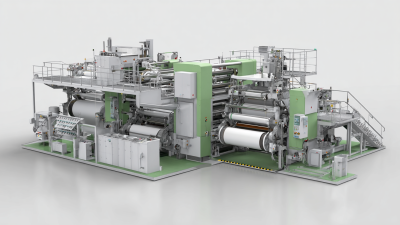

As the demand for batteries continues to surge, the focus on sustainable packaging materials is becoming increasingly crucial. The future of battery packaging lies in the ability to balance durability with eco-friendliness. Innovations such as biodegradable plastics, recycled materials, and innovative composites are paving the way for more sustainable solutions that not only protect the battery but also minimize environmental impact. By adopting these materials, manufacturers can significantly reduce waste and contribute to a circular economy.

Sustainable packaging not only addresses environmental concerns but also meets regulatory demands. As governments worldwide implement stricter guidelines on packaging waste, the battery industry must adapt to comply with these standards while maintaining efficiency. Exploring lab-scale battery packaging machine innovations that utilize sustainable materials can lead to breakthroughs in production capabilities. This proactive approach helps companies stay ahead in a competitive market, appealing to environmentally conscious consumers and stakeholders alike. Embracing these innovations could redefine industry standards and usher in a new era of responsible manufacturing.

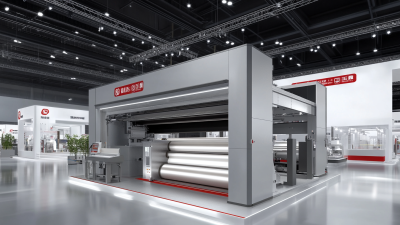

In the rapidly evolving landscape of battery manufacturing, the adoption of innovative packaging technologies is paramount for enhancing productivity. Recent studies indicate that the global battery packaging market is projected to reach $5.2 billion by 2026, growing at a CAGR of 6.5%. This growth is driven by the increasing demand for efficient packaging solutions that maximize throughput without compromising on quality. Innovations such as automated packaging lines and robotics are at the forefront, enabling manufacturers to streamline their operations significantly.

Advanced battery packaging machines prioritize both speed and precision, ensuring that each unit is securely packaged to withstand varying storage conditions. Data from the International Battery Association reveals that automating the packaging process can reduce labor costs by up to 30% while increasing production speeds by as much as 40%. With features like precise volume dispensing and real-time quality monitoring, these machines not only enhance operational efficiency but also improve overall product reliability.

As the industry continues to prioritize sustainability and efficiency, the integration of cutting-edge packaging technologies is essential for staying competitive in the market.

The integration of smart technology in battery packaging systems marks a transformative shift in the industry, enhancing both efficiency and precision. Advanced automation and IoT-enabled devices are now commonplace, allowing for real-time monitoring and adjustments during the packaging process. This smart integration not only streamlines operations but also minimizes human error, ensuring that each battery is securely and accurately packaged according to industry standards.

Moreover, the use of AI and machine learning algorithms in packaging machines is setting a new precedent for predictive maintenance and operational intelligence. These technologies analyze data collected during the packaging process to identify potential issues before they arise, reducing downtime and extending the lifespan of packaging equipment. The result is a more robust and responsive manufacturing environment that can adapt quickly to market demands while maintaining high-quality standards. With these innovations, the future of battery production is not only brighter but smarter.