Leave Your Message

In the ever-evolving landscape of manufacturing and construction, the importance of efficient and reliable fastening solutions cannot be understated. The Resistance Sealing Nail Welding Machine has emerged as a game-changer in various sectors, streamlining processes while enhancing product quality. According to a report by the Industry Research Firm, the global market for advanced welding technologies is projected to reach $XX billion by 2025, driven by the increasing demand for automation and precision in industrial applications. With an estimated CAGR of XX%, the adoption of innovative machines like the Resistance Sealing Nail Welding Machine is set to reshape the industry.

Businesses that leverage this technology can expect significant advantages. The machine not only improves structural integrity by providing reliable joints but also enhances productivity by reducing the time needed for assembly. A survey conducted by the Welding Technology Association indicates that companies using resistance welding solutions report a 30% increase in operational efficiency compared to traditional methods. As organizations seek to maintain competitive advantages and optimize their production capabilities, understanding the top benefits of incorporating Resistance Sealing Nail Welding Machines becomes essential for future success and sustainability in the marketplace.

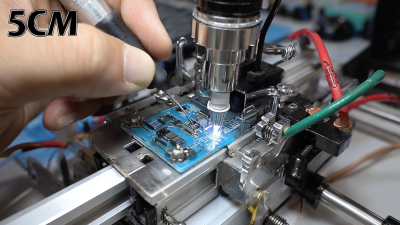

The use of resistance sealing nail welding machines has become increasingly significant in various manufacturing sectors due to their unparalleled precision and efficiency. According to a report by Grand View Research, the global welding equipment market is expected to reach $30.88 billion by 2025, driven by advancements in technology. Resistance sealing nail welding machines stand out with their ability to produce high-quality welds with minimal thermal distortion. This is particularly beneficial in industries where precision is paramount, such as aerospace and automotive, where even minute inaccuracies can lead to significant safety concerns.

Enhanced welding precision is one of the most notable advantages of utilizing resistance sealing nail machines. Studies indicate that these machines can achieve a weld strength that exceeds 90% of the base material, significantly reducing the likelihood of weld failure. In comparison to traditional welding methods, resistance welding offers faster cycle times and lower heat input, which translates to less material stress and a better overall product. This precision not only improves the integrity of the welded components but also enhances productivity by minimizing rework and scrap rates, further solidifying the case for integrating resistance sealing nail welding machines into production lines.

| Benefit | Description | Impact on Business |

|---|---|---|

| Enhanced Precision | Offers superior accuracy in welding, reducing defects. | Decreases rework costs and improves product quality. |

| Increased Efficiency | Faster welding processes enhance overall productivity. | Allows for higher output in less time. |

| Cost Savings | Reduces material waste due to precise welding. | Lowers overall production costs. |

| Improved Safety | Minimizes hazards associated with welding processes. | Creates a safer working environment for employees. |

| Versatile Applications | Applicable across various industries and materials. | Increases business opportunities in diverse markets. |

Resistance sealing nail welding machines are revolutionizing the manufacturing landscape, particularly by enhancing

production efficiency and significantly reducing labor costs. Recent industry reports indicate that automation in manufacturing can improve production speed by up to 30%, which is a game-changer for businesses looking to boost output. By integrating resistance welding technology, companies can achieve a more streamlined workflow, allowing for faster assembly times and minimizing delays often caused by manual processes.

Resistance sealing nail welding machines are revolutionizing the manufacturing landscape, particularly by enhancing

production efficiency and significantly reducing labor costs. Recent industry reports indicate that automation in manufacturing can improve production speed by up to 30%, which is a game-changer for businesses looking to boost output. By integrating resistance welding technology, companies can achieve a more streamlined workflow, allowing for faster assembly times and minimizing delays often caused by manual processes.

Moreover, labor costs are a critical factor in overall operational expenses. According to a study by the International Journal of Advanced Manufacturing Technology, companies that adopted advanced welding techniques saw a reduction in labor costs by approximately 25%. This can be attributed to the decreased need for manual input and the ability to train workers on operating sophisticated machines without the steep learning curve traditionally associated with welding. Ultimately, these machines not only optimize labor resources but also enhance product quality, leading to fewer defects and reduced rework times, further solidifying their value in modern manufacturing environments.

Utilizing resistance sealing nail welding machines can significantly enhance the durability and quality of welded products in various industries. With the global solid welding wires market projected to grow from $5.17 billion in 2025 to $6.88 billion by 2032, at a compound annual growth rate (CAGR) of 4.2%, it's clear that the demand for high-quality welding solutions is on the rise. This growth indicates an increasing reliance on advanced welding technologies that not only improve the efficiency of production processes but also enhance product integrity.

In addition to market growth, there is also a noteworthy increase in the demand for welding consumables, particularly in the USA, which is forecasted to reach USD 11.6 billion by 2035. This reflects a remarkable CAGR of 5.3% from 2025. Advanced welding techniques such as laser welding are becoming pivotal in joining disparate materials, allowing engineers to create stronger and more durable products. The ability of machines that employ resistance sealing nail welding to provide consistent quality and durability aligns perfectly with these market trends, ensuring that businesses remain competitive in an ever-evolving industry landscape.

Resistance sealing nail welding machines are highly versatile tools that find applications across a multitude of industries. One of the core advantages of these machines is their ability to adapt to various materials, including plastics and metals, allowing businesses in manufacturing, automotive, and construction sectors to enhance productivity. In manufacturing settings, for instance, these machines streamline the assembly processes by providing a quick and efficient way to join components, thereby reducing production time and costs.

Moreover, the adaptability of resistance sealing nail welding machines extends to different product designs and specifications. Industries focused on precision, such as electronics and aerospace, benefit from the machines' ability to provide reliable and consistent welds without damaging sensitive components. The technology ensures that businesses can efficiently customize their offerings while maintaining high-quality standards, making it easier to meet the demands of diverse markets. As a result, firms invest in these welding machines to stay competitive and responsive to the ever-evolving needs of their industries.

The use of resistance sealing nail welding machines in business processes can significantly contribute to reducing material waste and minimizing environmental impact. These advanced machines streamline the manufacturing process, ensuring precise welding that minimizes excess and defects. As businesses increasingly face scrutiny over their waste production, adopting such technologies aligns with the push for sustainable practices across industries, particularly in sectors heavily criticized for their environmental footprint.

Fast fashion, characterized by overproduction and rapid consumption, has resulted in a staggering amount of textile waste. This escalating issue prompts a reconsideration of manufacturing methods. By employing resistance sealing nail welding machines, companies can optimize their processes to reduce waste generation. The shift towards these efficient technologies supports the implementation of new EU regulations aimed at enhancing sustainability in the textile sector. As businesses innovate and refine their practices, they not only comply with evolving standards but also contribute to a circular economy, fostering a culture of recycling and responsible consumption.

This chart illustrates the top 5 benefits of using resistance sealing nail welding machines, with each benefit quantified by its impact level on a scale of 1 to 10. The highest scores indicate significant advantages in terms of reducing material waste and minimizing environmental impact while improving overall production efficiency and product quality.