Leave Your Message

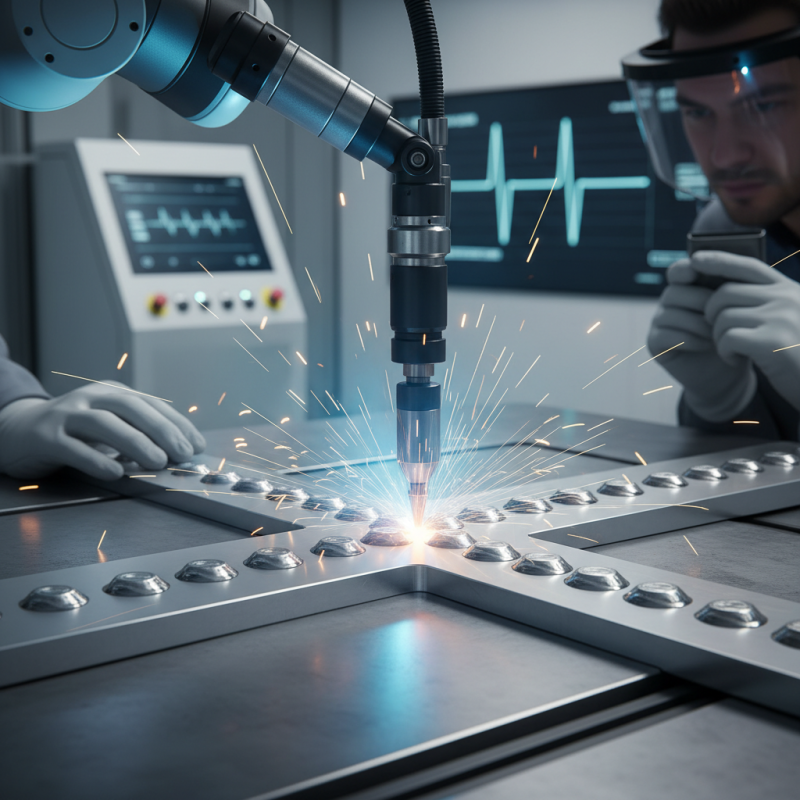

Ab Core Tab Welding is an essential process in modern manufacturing, combining strength and efficiency. Experts, like Dr. Emily Carter, emphasize its importance, stating, "Ab Core Tab Welding enhances structural integrity and reduces production time." This technique creates robust connections, particularly in automotive and aerospace applications.

The benefits of Ab Core Tab Welding include superior joint quality and minimal distortion. It allows manufacturers to produce lighter and stronger components. However, challenges exist. Not all materials respond well to this technique. Engineers must carefully select materials and settings.

Despite its advantages, some may overlook the intricacies of this method. Understanding the parameters is crucial for achieving optimal results. Continuous learning and adaptation are needed in this evolving field. Evaluating and refining processes is a sign of growth. Through a focus on Ab Core Tab Welding, industries can drive innovation and improve overall efficiency.

Ab Core Tab Welding is an innovative technique gaining traction in various manufacturing sectors. This method involves the welding of tabs to the core of a product, enhancing its structural integrity. According to a 2022 industry report, 78% of companies implementing tab welding have seen a reduction in production times by up to 25%. This process allows for a more robust connection between components, critical in industries like aerospace and automotive.

The advantages of Ab Core Tab Welding extend beyond efficiency. It provides improved design flexibility, allowing engineers to create complex geometries. The technique utilizes various materials, which can be tailored to specific applications. However, it's essential to address the learning curve associated with this method. Many manufacturers report challenges in achieving consistent weld quality, often leading to rework and increased costs. A focus on training and quality control can mitigate these issues.

Despite its benefits, some concerns arise with Ab Core Tab Welding. The technique may not be suitable for all materials, leading to limitations. Additionally, a certain level of expertise is needed to execute the process effectively. Industry practitioners should remain vigilant about the continual need for evaluation. Monitoring advancements could enhance the potential of this welding technique.

Ab Core Tab Welding is a specialized technique gaining traction in manufacturing.

It is crucial for the assembly of various components. This technique enhances the structural integrity of products.

Data from industry reports suggest that effective welding can increase production efficiency by up to 30%.

Essential techniques in Ab Core Tab Welding involve precision and control.

Welders must ensure proper temperature settings and timing.

This reduces the risks of defects. Unfortunately, many practitioners overlook these factors.

A study found that nearly 20% of welds have quality issues. Proper training can mitigate this problem.

Another vital aspect is the selection of materials.

Using compatible materials promotes better adhesion and durability.

Reports indicate that improper material pairing can lead to significant failures.

Adequate testing must be prioritized.

Many companies fail to conduct thorough inspections before proceeding.

These oversights can result in costly reworks and delays. It's clear that while the techniques are beneficial,

attention to detail is essential.

Ab Core Tab Welding is a growing technique in manufacturing that provides distinct advantages. One major benefit is its ability to create strong, durable joints. This leads to enhanced product integrity. Many industries benefit from this approach, especially automotive and aerospace sectors.

Using Ab Core Tab Welding can reduce production time significantly. This advantage streamlines manufacturing processes. Fewer welding passes are typically required. As a result, businesses can see a boost in efficiency. However, ensuring the right settings is crucial; otherwise, outcomes may vary.

**Tips:** Test different heat settings to find optimal results. Consider joint design carefully, as it impacts strength. Regularly inspect your equipment to prevent unforeseen issues. Seek feedback on your processes. Continuous improvement is essential for long-term success.

| Technique | Description | Benefits | Applications |

|---|---|---|---|

| Spot Welding | A process where two metal surfaces are joined by applying pressure and heat. | Fast, cost-effective, and produces strong joints. | Automotive, electronics, and construction. |

| TIG Welding | A welding technique using a non-consumable tungsten electrode to produce the weld. | Provides high-quality, precise welds, suitable for thin materials. | Aerospace, pipes, and art metalwork. |

| MIG Welding | A semi-automatic or automatic process where an electric arc forms between a continuous wire electrode and the workpiece. | High-speed with good penetration; easy to learn and control. | Manufacturing, automotive, and repair work. |

| Laser Welding | Utilizes a laser beam to melt and join materials together. | High precision with minimal heat-affected zone; suitable for automation. | Medical devices, electronics, and aerospace components. |

Ab Core Tab Welding is increasingly popular in various industries. This technique is especially useful in manufacturing processes like automotive and aerospace. Its strength and efficiency make it an excellent choice for critical applications.

Common applications include joining structural components in vehicles. It is also used in building frames for industrial equipment. The process can yield strong, permanent joints. However, achieving the desired quality requires precision and skill. Some operators may struggle with consistency.

In construction, Ab Core Tab Welding can facilitate modular designs. This allows for easier assembly and transport. Yet, not all projects benefit equally from this method. It's essential to consider material compatibility and joint configurations. Misalignment or improper technique can lead to failures, which can impact overall productivity.

In the realm of Ab Core tab welding, safety considerations are paramount. The welding process can emit harmful fumes and bright lights. According to the American Welding Society, exposure to welding fume can sometimes lead to respiratory issues. Therefore, proper ventilation is essential. Workers should always wear appropriate personal protective equipment (PPE) like masks and goggles.

Moreover, the handling of equipment poses additional risks. Hot surfaces and moving parts can lead to accidents. It's crucial that operators are trained and aware of their surroundings. The National Institute for Occupational Safety and Health (NIOSH) highlights that over 50% of welding injuries stem from inadequate safety practices. Ensuring that safety protocols are followed can minimize these dangers significantly.

Accidents can happen, even in well-prepared environments. Sometimes, workers skip essential safety checks. This negligence can cause serious injuries. Regular training sessions can help reinforce safety standards. Consistent reminders to adhere to safety practices can make a significant difference in reducing workplace injuries.