Leave Your Message

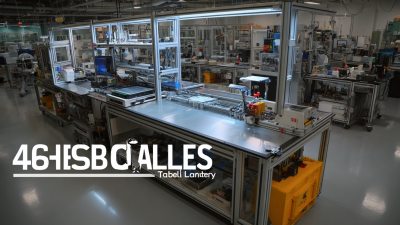

The emergence of the 4680 Tabless Battery Lab Line is set to revolutionize the energy storage landscape, addressing the growing demand for more efficient and sustainable battery solutions. According to a recent report by the International Energy Agency (IEA), global energy storage capacity is expected to reach over 2,500 GWh by 2040, highlighting the urgent need for innovations in battery technology. The tabless design of the 4680 cells enables a significant reduction in materials used, enhances thermal management, and improves energy density, potentially increasing vehicle range and performance. This advanced manufacturing approach is not just a technical leap; it is a pivotal step towards achieving cost-effective mass production, as highlighted in Tesla's sustainability goals. As industries strive to cut carbon emissions and transition to renewable energy sources, the 4680 Tabless Battery Lab Line positions itself as a game-changer, promising to reshape how we think about energy storage solutions for electric vehicles and beyond.

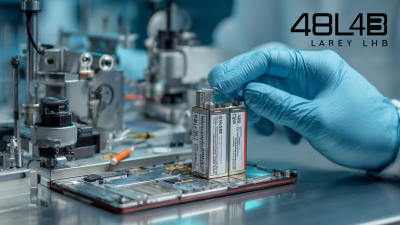

The 4680 tabless battery technology is a groundbreaking advancement in energy storage solutions, primarily driven by its innovative structure and design. Unlike traditional battery cells that utilize tabs for current collection, the 4680 design eliminates these tabs, leading to enhanced efficiency in both production and performance. According to a report by IDTechEx, the tabless design allows for a 14% increase in energy density and a 20% reduction in production costs. These improvements are critical for the electric vehicle (EV) market, where higher energy density translates into longer driving ranges and reduced charging times.

The structural integrity of the 4680 cells further enhances their performance. With a cylindrical shape that utilizes a winding method, the design maximizes the active material within the cell, resulting in a significant increase in energy storage capacity. A study by the International Energy Agency (IEA) highlighted that advancements in battery technology, such as the tabless design, could lead to a 30% reduction in overall battery costs by 2030. This transformation is essential for scaling up renewable energy storage solutions and improving the sustainability of battery production, ultimately driving the transition to greener energy alternatives.

| Feature | Description | Benefit | Application |

|---|---|---|---|

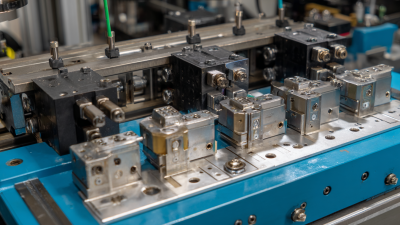

| Tabless Design | Eliminates tabs that typically connect cells and terminals. | Reduces internal resistance, improving efficiency. | Electric Vehicles and Energy Storage Systems. |

| Higher Energy Density | Enables more energy to be stored in a compact form. | Increases driving range and reduces weight. | Portable Electronics, Electric Vehicles. |

| Simplified Manufacturing | Integrates multiple manufacturing processes into one. | Reduces overall production costs and time. | Battery Production Facilities. |

| Scalability | Designed to be easily scalable for mass production. | Meets growing demand in energy markets. | Global Energy Markets. |

| Environmental Impact | Constructed with more recyclable materials. | Lowers the carbon footprint of battery manufacturing. | Sustainable Energy Solutions. |

The tabless structure of the 4680 battery represents a significant advancement in the realm of energy density and heat management. Unlike traditional battery designs, which rely on tabs to connect individual cells, the tabless architecture optimizes the flow of electricity and reduces resistance. This streamlined approach not only enhances energy density but also allows for improved thermal management, addressing one of the pivotal challenges in electric vehicle technology. Enhanced thermal performance diminishes the risk of overheating, thus promoting longevity and safety in battery operation.

Moreover, the transition toward electric vehicles (EVs) necessitates advancements in energy storage solutions that can meet the demands of higher driving ranges and rapid charging. The innovations embodied in the tabless battery design align with these needs by providing greater efficiency and delivering power more reliably. As EV technology evolves, the integration of such advanced battery systems could serve as a foundation for future developments, enabling a more sustainable transportation landscape that leverages improved energy management strategies. The benefits of a tabless structure extend far beyond mere energy density, ushering in a new era of effective heat management within the rapidly advancing electric vehicle market.

The introduction of the 4680 tabless battery design marks a significant turning point in the electric vehicle (EV) industry, particularly in enhancing range and performance. According to a report by IDTechEx, Tesla’s innovative battery design could potentially increase energy density by 5-10% compared to traditional cylindrical batteries. This improvement allows for lighter battery packs, which translates to a broader range for EVs without the need for larger battery systems.

Additionally, the tabless structure minimizes electrical resistance and increases the efficiency of charge cycles. Research indicates that this design can lead to faster charging times, possibly reducing the duration to as little as 15 minutes for substantial charge levels. Such advancements could make electric vehicles more practical for everyday use, alleviating range anxiety among consumers and promoting broader adoption in the automotive market.

Tips: To maximize the benefits of 4680 batteries, EV manufacturers should focus on optimizing thermal management systems, as improved heat dissipation can further enhance battery life and performance. Additionally, keeping abreast of ongoing advancements in solid-state technology will be essential for future iterations of battery designs.

The introduction of the 4680 tabless battery technology represents a significant shift in energy storage solutions, particularly in comparison to traditional battery technologies. Recent analyses indicate that the average cost of producing lithium-ion batteries has dramatically decreased, attributed to advancements in manufacturing processes, including the adoption of tabless designs which streamline production and enhance energy density. A comparative study suggests that while traditional cylindrical or prismatic batteries average around $150 per kWh, the 4680 tabless battery could reduce costs to approximately $100 per kWh due to its simpler structure and less material waste.

Moreover, the energy-density improvements associated with the 4680 design are poised to boost electric vehicle (EV) performance substantially. Current reports highlight that the effective use of innovative configurations in battery production not only contributes to greater efficiency but also aligns with the automotive industry's shift towards sustainability. As the EV market moves towards broader adoption, these cost benefits and performance gains are essential for meeting the increasing demand for batteries, which is projected to reach over 2,000 GWh annually by 2025. The transformation initiated by the 4680 tabless battery technology is thus not just a technical advancement but also a strategic response to the economic pressures currently facing the energy storage sector.

The emergence of the 4680 tabless battery technology marks a significant leap forward in energy storage solutions, promising a more efficient and sustainable future. One of the most noteworthy innovations is the design’s reduction of internal resistance, which enhances energy density and overall performance. This allows electric vehicles (EVs) to achieve longer ranges while decreasing charging times. Such advancements not only benefit consumers, who seek reliable and powerful energy sources, but they also support the broader push towards greener transportation solutions.

As industry leaders adopt these innovations, the implications extend beyond the EV market. The 4680 battery's potential for mass production opens doors for advancements in renewable energy storage systems. Improved energy density and scalability mean that solar and wind energy can be stored more efficiently, making these renewable sources more viable options for powering homes and businesses. Consequently, the innovations derived from the 4680 battery design are set to reshape the entire energy landscape, fostering a transition to cleaner and more resilient energy infrastructure.

As industry leaders adopt these innovations, the implications extend beyond the EV market. The 4680 battery's potential for mass production opens doors for advancements in renewable energy storage systems. Improved energy density and scalability mean that solar and wind energy can be stored more efficiently, making these renewable sources more viable options for powering homes and businesses. Consequently, the innovations derived from the 4680 battery design are set to reshape the entire energy landscape, fostering a transition to cleaner and more resilient energy infrastructure.