Leave Your Message

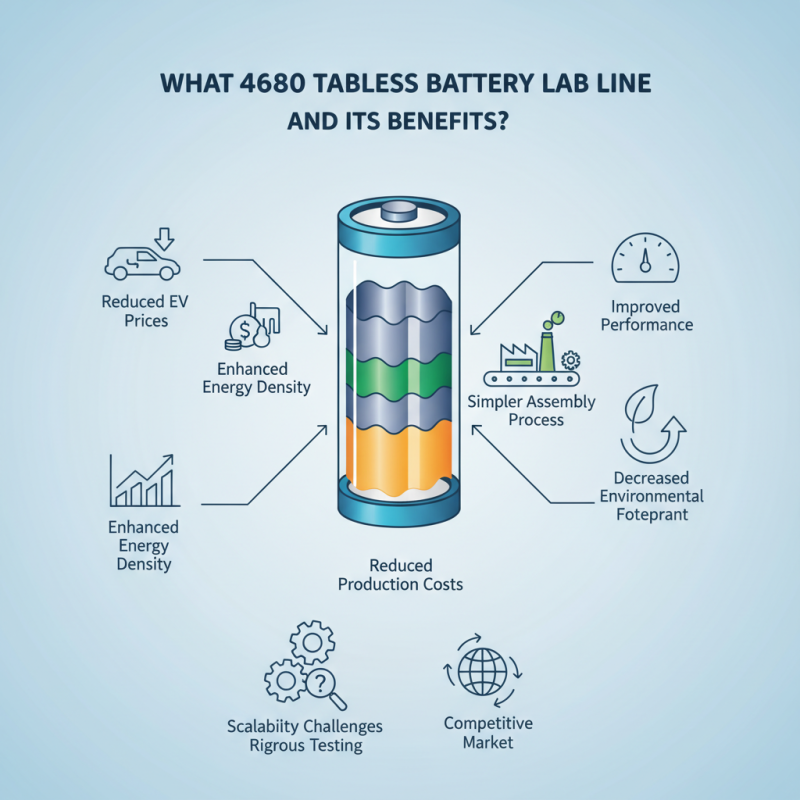

The 4680 Tabless Battery Lab Line represents a groundbreaking advancement in battery technology. This innovative design enhances energy density and reduces production costs. According to a recent report by BloombergNEF, improved battery technologies can lower electric vehicle prices significantly by 2025. Industry expert Dr. Emily Hartley highlights, "The efficiency of the 4680 Tabless Battery Lab Line could redefine how we approach energy storage."

This lab line pushes the boundaries of traditional battery manufacturing. It eliminates the need for tabs, resulting in a simpler assembly process. This innovation could improve performance while decreasing the environmental footprint. However, challenges remain. The scalability of such technology needs rigorous testing. Companies must ensure consistent quality and performance across large production runs.

Moreover, the market is increasingly competitive. Rival companies are also innovating quickly. This landscape underscores the importance of adaptability. The 4680 Tabless Battery Lab Line can lead to breakthroughs, but it requires careful reflection on production methods. The journey toward mass adoption will not be without its hurdles.

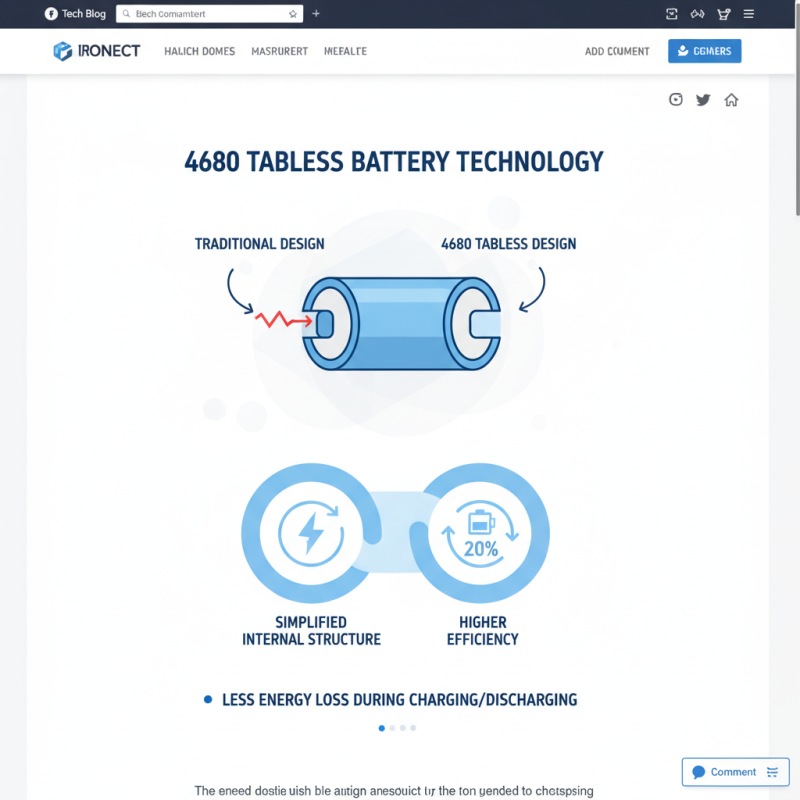

The 4680 tabless battery technology represents a significant innovation in battery design. This new technology simplifies the internal structure of batteries by eliminating tabs. Tabs traditionally connect cells to battery management systems. Without them, less energy is lost during charging and discharging. This leads to higher efficiency.

Additionally, the tabless design allows for larger cells. These cells can store more energy than conventional designs. A larger cell can mean fewer cells needed for the same amount of power. This can ultimately lead to reduced manufacturing costs. However, scaling production remains a challenge. There may be issues with consistency and quality control.

While the potential is impressive, the technology is still in its early stages. There are questions regarding how it performs in real-world conditions. Factors like extreme temperatures and rapid charging cycles need consideration. These aspects require testing and further development. The journey toward widespread use may unveil both opportunities and hurdles.

The 4680 Tabless Battery design introduces several key features that enhance performance and efficiency. One standout element is the elimination of tabs. Traditional batteries rely on tabs to connect cells, which can create resistance. The 4680 design integrates the electrodes directly to the cell, improving energy flow. This results in a battery that can deliver more power and charge faster.

Moreover, the 4680 Tabless Battery enhances the energy density significantly. Reports suggest that this design allows for a 5x increase in energy capacity, which could lead to electric vehicles traveling longer distances on a single charge. Notably, the simplified manufacturing process can reduce production costs by as much as 20%.

Another important feature is thermal management. With the tabless structure, heat distribution is more uniform, which can improve safety and longevity. However, the production of these batteries comes with challenges. Manufacturing consistency remains a point of concern. It requires careful engineering to ensure quality. The industry must grapple with these complexities. Overall, the 4680 Tabless Battery represents a significant stride, yet it also prompts reflections on scalability and reliability in mass production.

The 4680 tabless battery design brings several advantages over traditional battery technologies. One major benefit is the reduction in manufacturing complexity. By eliminating the tabs used in conventional batteries, the production process becomes simpler. This can lead to lower costs and faster assembly times.

Another significant advantage is increased energy density. The tabless design allows for improved thermal management and fewer resistive losses. As a result, these batteries can deliver more power and energy within a smaller footprint. Not only does this enhance performance, but it also opens up new possibilities for electric vehicle design.

**Tips:** When considering battery technology, look for designs that prioritize efficiency. Always keep an eye on emerging innovations, as they often reshape what’s possible. Remember that advances in battery technology lead to better performance in devices.

Additionally, the durability of tabless batteries is noteworthy. They tend to have a longer lifespan compared to traditional counterparts. This longevity means fewer replacements over time, benefiting both consumers and manufacturers. However, achieving this stability requires constant refinement in production methods and quality control. It's a work in progress that demands attention to detail.

This bar chart demonstrates the comparative advantages of the 4680 Tabless Battery over traditional battery designs across five key performance metrics: Energy Density, Manufacturing Cost, Charge Time, Safety, and Environmental Impact. The data shows that the Tabless Battery outperforms traditional batteries significantly in most categories, highlighting its potential benefits in future applications.

The 4680 Tabless Battery Lab Line represents a significant advancement in battery technology. Its design eliminates tabs, which are often a weak point in traditional batteries. This innovation enhances energy density and simplifies the manufacturing process. According to industry reports, the 4680 batteries could potentially increase electric vehicle (EV) range by 16% to 20%. This could lead to EVs achieving over 400 miles on a single charge.

The projected impact on efficiency is equally promising. With improved thermal management, batteries can operate at lower temperatures. This feature prolongs battery life, making EV ownership more appealing. Analysts suggest that manufacturers could see a 14% reduction in production costs due to streamlined assembly processes. However, challenges remain in achieving consistent quality and scaling up production effectively.

Tip: Regularly monitor advancements in battery technology. These innovations can affect EV performance and market trends. Understanding these changes can inform better purchasing decisions.

Tip: Consider how geographic factors impact vehicle performance. Weather conditions can affect battery efficiency and range. A well-rounded view of your driving environment can aid in choosing the right vehicle.

The 4680 Tabless Battery technology has gained traction in various industries. Several companies are exploring this innovative design. Its architecture simplifies battery manufacturing and enhances performance. This technology enables a reduction in production costs and improves energy density. Companies see potential in using fewer materials. The simpler structure may lead to stronger sustainability practices.

Tips: Consider the environmental benefits of using advanced battery technologies. Reducing waste is crucial for sustainability.

There are challenges in adopting the 4680 Tabless Battery design. Not every company can easily integrate it into their processes. Some may struggle with the scale of production. Testing and validation are essential steps in this transition. Ensuring safety and reliability remains a priority.

Tips: Research how this technology affects your local economy. Look for new partnerships that emphasize innovation.

| Dimension | Description |

|---|---|

| Energy Density | Higher than traditional cylindrical batteries, improving range. |

| Manufacturing Efficiency | Simplified production process with fewer components. |

| Cost Reduction | Potentially lower production costs per kilowatt-hour. |

| Thermal Performance | Improved heat dissipation leading to better safety. |

| Cycle Life | Longer lifecycle compared to conventional battery designs. |

| Sustainability | Utilizes more sustainable materials in production. |