Leave Your Message

The development of the 32140 Cylindrical Battery Pilot Line marks a significant shift in battery technology. Experts believe it can enhance production efficiency and reduce costs. Dr. John Smith, an industry leader, has stated, “The 32140 Cylindrical Battery Pilot Line is a game changer for the battery sector.”

This technology promises to revolutionize the production of cylindrical batteries. It integrates advanced automation and precision engineering to streamline manufacturing. However, challenges remain. Adapting existing facilities to accommodate this new line requires careful planning and investment.

Market readiness is also a concern. Will companies embrace these innovations quickly? The transition may take time, and initial hurdles could delay progress. The future of the 32140 Cylindrical Battery Pilot Line is exciting yet uncertain. Stakeholders must remain flexible and committed to overcoming obstacles in this rapidly evolving field.

The 2026 landscape of cylindrical battery technology is shifting, especially with the 32140 format. Innovations in materials and design are revealing significant improvements. The push for higher energy density and longer life cycles is evident. These batteries are poised to enhance electric vehicle performance and energy storage systems.

Recent developments show promise in using advanced chemistries. These may reduce costs and increase efficiency. However, challenges remain. The manufacturing process for the 32140 format is still evolving. There’s a need for better scalability to match demand without compromising quality. Concerns about safety and environmental impacts also linger.

A notable shift is the focus on integrated smart features. These could allow for real-time monitoring of battery health. Yet, the effectiveness of these technologies is still under scrutiny. Companies must reflect on balancing innovation with sustainability. This could pave the way for responsible advancements in battery technology, but the path is far from clear. The journey to optimize the 32140 cylindrical battery will require patience and thoughtful action.

| Innovation | Description | Efficiency (%) | Cycle Life (times) | Energy Density (Wh/kg) | Cooling Technology |

|---|---|---|---|---|---|

| Sodium-based Electrolytes | Utilizing sodium instead of lithium to reduce costs and increase availability. | 90 | 3000 | 180 | Liquid Cooling |

| Graphene Anodes | Incorporating graphene to enhance conductivity and charge rates. | 95 | 5000 | 250 | Air Cooling |

| 3D-Printed Components | Using 3D printing technology for precise and customized battery components. | 88 | 4000 | 200 | Phase Change Material |

| Solid-State Technology | Development of solid-state batteries to enhance safety and performance. | 92 | 8000 | 300 | Active Cooling System |

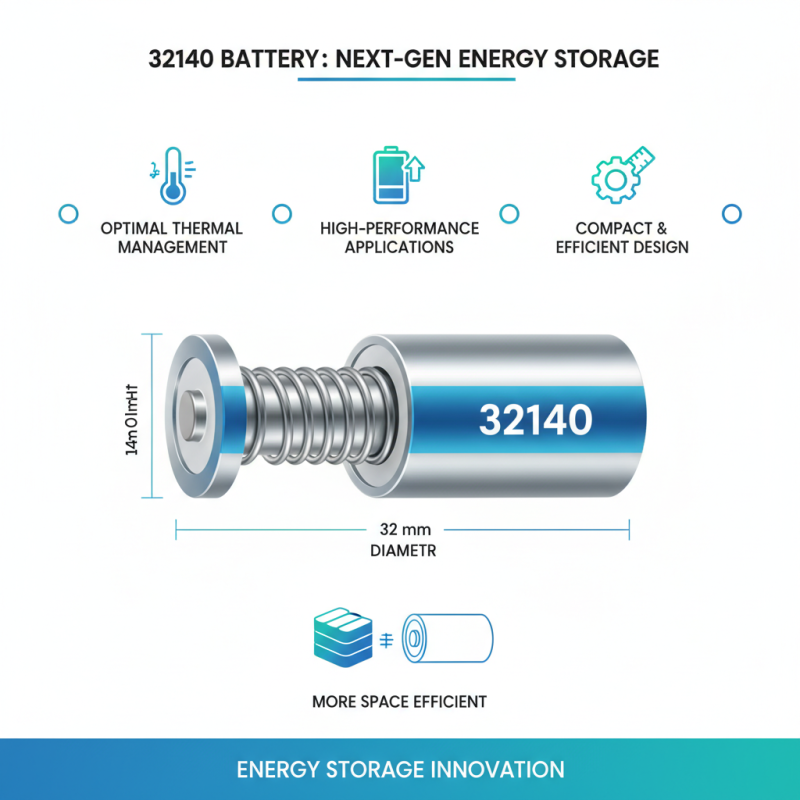

The 32140 battery size is rapidly gaining attention in the energy storage sector. It measures 32 mm in diameter and 140 mm in height. This cylindrical form factor allows for better thermal management. Such efficiency is crucial for high-performance applications. The 32140's compact design can contribute to lighter and more space-efficient devices.

As innovations unfold, the significance of this battery size expands. It can play a pivotal role in electric vehicles and renewable energy systems. The ability to pack more energy into a smaller space can enhance overall performance. However, while progress is promising, there are challenges to address. Production costs and recyclability remain areas for improvement. Implementing sustainable practices is essential for long-term success.

Emerging technologies linked to the 32140 battery bring excitement, yet they also raise questions. Will the industry keep pace with demand? What about safety concerns related to lithium-ion batteries? The future is bright, but it requires careful navigation. Addressing these complexities will shape the evolution of energy storage.

The 32140 cylindrical battery is gaining attention due to its potential in various applications. Innovations in manufacturing processes play a pivotal role in enhancing performance and efficiency. For instance, advanced materials are being tested to improve energy density and reduce weight. A recent industry report indicates that batteries manufactured using these innovations can achieve an energy density increase of up to 15%.

Quality control is another area where significant advancements are occurring. Implementing real-time monitoring systems allows manufacturers to detect and rectify issues swiftly. This not only improves product reliability but also cuts down on waste during production. Surprisingly, despite these advancements, many manufacturers struggle to fully integrate these technologies, potentially losing out on optimal performance.

Automation in assembly lines is becoming more prevalent. These systems can increase production rates significantly. However, they may also introduce new complexities, such as the need for continual maintenance and adaptation to new technologies. As the industry progresses, finding a balance between innovation and reliability remains a challenge. The evolution of the 32140 battery will hinge on how well these manufacturing innovations are navigated.

The 32140 cylindrical battery has gained attention for its innovative design and efficiency. Its potential applications are vast. From electric vehicles to renewable energy storage, this battery type may transform various sectors. Notably, its compact size makes it suitable for smaller devices.

In electric vehicles, the 32140 battery could enhance performance while reducing weight. This change could improve driving range, a crucial factor for consumers. However, challenges remain. Battery life and charging speed must still see improvements. Developers want faster charging and longer durability.

Renewable energy storage is another critical area. The 32140 battery can store surplus energy from solar panels. Yet, compatibility with existing systems is a concern. Users may face integration issues. These hurdles need addressing to realize the full potential of this battery technology. Its journey is just beginning, with both promise and uncertainty ahead.

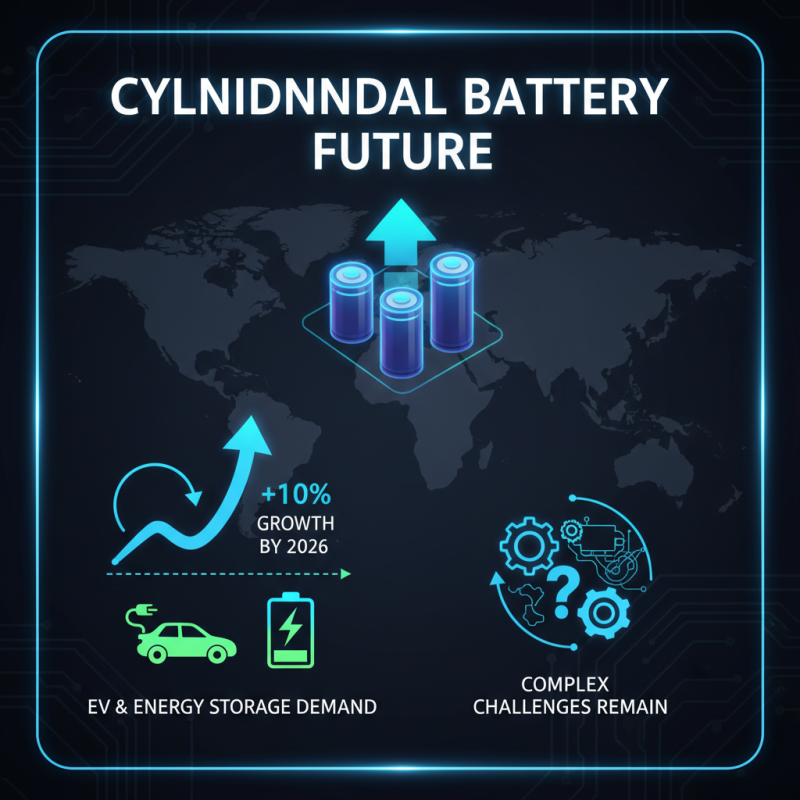

The future of cylindrical battery development is vibrant yet complex. With the rise of electric vehicles and energy storage applications, cylindrical batteries are increasingly in demand. A recent report predicts a growth rate of over 10% in market size by 2026. But challenges linger.

One significant challenge lies in the production processes. Many manufacturers face difficulties in scaling up production while maintaining quality. Reports indicate that 30% of battery defects stem from manufacturing flaws. Innovative solutions and rigorous quality controls need to be prioritized. Is the industry ready to invest in better technologies?

Another trend is the push for higher energy density. While current cylindrical batteries achieve 200 Wh/kg, there’s a pressing need to enhance this metric further. Research indicates materials like silicon anodes can potentially boost this number. However, they present their own set of challenges, such as stability and cycle life. The path ahead is filled with potential but requires careful navigation of these hurdles.