Leave Your Message

In the world of battery technology, understanding the importance of Battery Sleeve Labing is crucial. This process directly affects how batteries perform under various conditions. Proper labing ensures that batteries are used efficiently and safely. Many users overlook this aspect, leading to reduced battery lifespan.

Consider a situation where a battery is improperly labeled. It may be used in the wrong device. This can result in malfunction or damage. It is essential to recognize the significance of accurate labing for optimal performance.

Even experienced users can make mistakes. They may forget to check the specifications. Incomplete or incorrect labeling can lead to complications. This article will explore best practices for Battery Sleeve Labing. We aim to help users maximize their battery’s potential and minimize risks, fostering a better understanding of this often-neglected aspect.

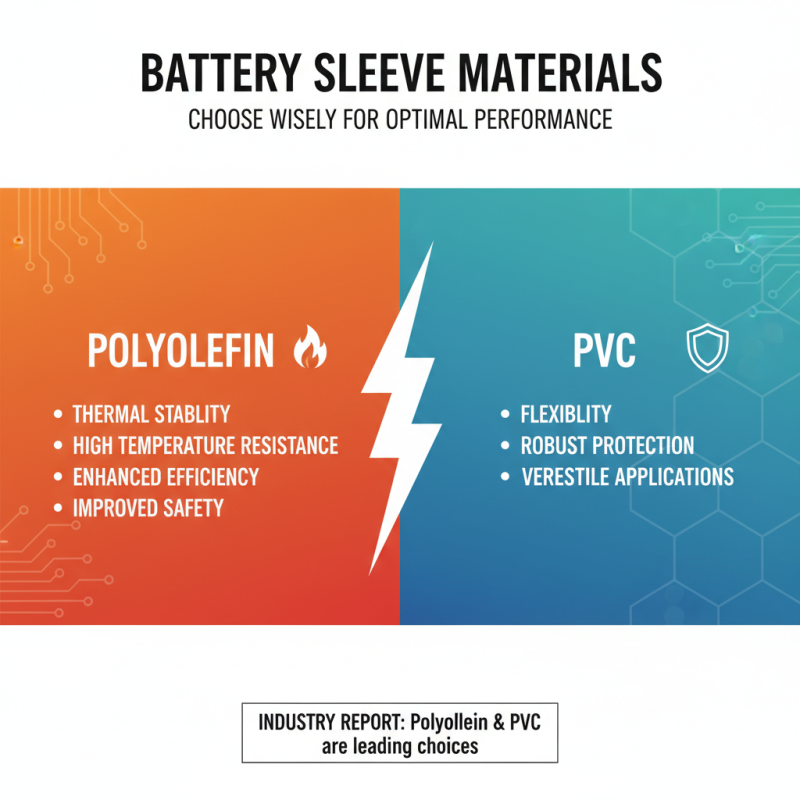

When choosing battery sleeves, selecting the right material is crucial for performance. According to recent industry reports, polyolefin material offers excellent thermal stability. It withstands higher temperatures better than many alternatives. This enhances battery efficiency and safety. Another material to consider is PVC, known for its flexibility and robust protective qualities. Both options show effectiveness in various applications.

Here are some tips for choosing the right sleeve material. Always check the manufacturer's specifications for compatibility. The wrong material can lead to overheating or even battery failure. Look for materials that provide good insulation and chemical resistance. This minimizes risks associated with battery leaks. Regular testing of sleeves can also reveal degradation over time, highlighting the need for replacements.

While many opt for the most common choices, consider less popular options too. Some newer materials may perform better but lack industry trust. Relying solely on established materials can stifle innovation. Experimenting with alternatives could yield surprising results. Reflect on your choices and the long-term impact on battery performance. Decisions made today can affect efficiency tomorrow.

When it comes to battery performance, proper sizing and fit are crucial. A battery sleeve should snugly fit the battery without excessive tension. An ill-fitting sleeve can restrict airflow, leading to overheating. If the sleeve is too loose, it might not provide adequate protection. Choosing the right material is also important; some materials offer better heat resistance than others.

Pay attention to details. Measure the battery carefully before selecting a sleeve. Even small size discrepancies can lead to significant performance issues. If you notice your battery becoming too hot or discharging too quickly, consider re-evaluating the fit. A sleeve should not just be a cover; it should enhance overall performance.

It's easy to overlook these factors. Many users simply grab any sleeve that looks right. The truth is, a few minutes spent ensuring proper fit can save time and money in the long run. Think about the implications of a poor fit. Better performance is just a sleeve away.

Battery sleeves can significantly enhance the longevity and performance of batteries. However, proper maintenance is often overlooked. According to industry reports, approximately 25% of battery failures are due to inadequate care. Cleaning and managing your battery sleeves can greatly reduce this risk. Regular inspection should become a habit. Look for dirt or grime that may have accumulated over time.

Cleaning battery sleeves is simple yet vital. Use a soft, dry cloth to wipe the surface. For stubborn stains, a damp cloth can be effective. Avoid harsh chemicals as they might degrade the material. Research shows that neglecting cleanliness can lead to a 15% drop in battery efficiency. Keeping battery sleeves in a dry environment also helps. Humidity can corrode and damage the battery.

Don’t forget to replace worn-out sleeves promptly. Weak sleeves cannot adequately protect your batteries. It’s a small cost for big benefits. Additionally, storing unused batteries with their sleeves can prevent dust buildup. These little actions contribute to optimal performance and extend battery life. Overlooking these steps may cost you in the long run.

Understanding temperature effects on battery sleeve performance is crucial for maximizing efficiency. Battery sleeves are designed to provide insulation and protect against extreme temperatures. Research shows that batteries operate best within 20°C to 25°C. At higher temperatures, chemical reactions accelerate, leading to a faster degradation of battery life. Conversely, low temperatures can hinder the battery's ability to deliver power effectively.

One tip is to monitor your battery sleeves regularly. If they show signs of wear, consider replacing them. Insulation properties diminish over time. Another tip involves storage practices. Always store batteries in a temperature-controlled environment. Avoid direct sunlight or cold places. This can help prolong battery life.

It's also important to remember that not all sleeves are equal. Some may not provide adequate protection under specific conditions. A study from the International Battery Association highlights that poorly insulated batteries can lose up to 30% of their performance at extreme temperatures. Thus, reconsidering the type of sleeves you use based on your environment can lead to better performance.

When it comes to storing and handling battery sleeves, several best practices can enhance their performance. Proper storage is key. Keep them in a dry, cool place away from direct sunlight. Extreme temperatures can ruin battery efficiency. If you notice any corrosion, take action immediately. A damaged battery sleeve can lead to further complications.

Handling is equally important. Always handle battery sleeves with clean hands. Contaminants can affect their longevity. Avoid dropping them; even minor impacts can create unseen damage. Keep them away from sharp objects in your bag. These everyday scenarios can lead to deterioration.

Tips to remember: Label your batteries. It brings organization and makes finding them easier. Check for any signs of wear often. Regular inspections help catch issues early. Storing batteries in their original packaging can prevent unexpected mishaps. Inconsistent practices can lead to poor performance. Reflect on your current methods and make improvements where necessary.