Leave Your Message

As we venture into 2025, the landscape of technological innovation continues to evolve, presenting new opportunities and challenges in various industries. One significant advancement is in the realm of Ab Core Tab Welding, a critical process in battery manufacturing that enhances energy efficiency and performance. According to a recent industry report by Research and Markets, the global battery market is projected to reach $120 billion by 2025, driven by the surge in electric vehicles and renewable energy solutions. The demand for efficient welding solutions is at an all-time high, and selecting quality manufacturers that specialize in Ab Core Tab Welding is crucial for achieving optimal outcomes. By understanding the key advantages and features of the best solutions available, businesses can make informed decisions to enhance productivity and ensure industry-leading standards in their manufacturing processes.

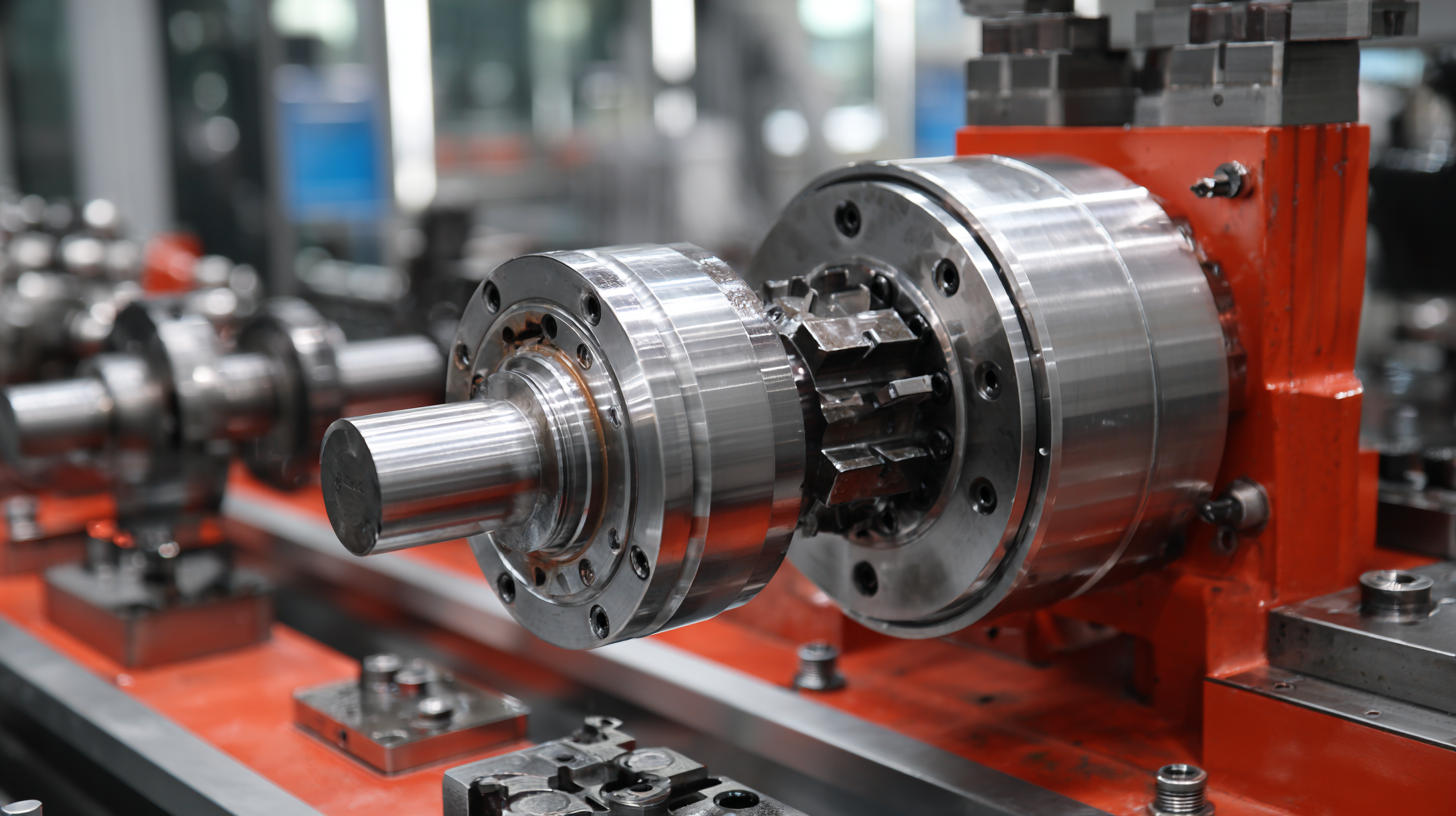

The advancements in Ab Core Tab welding technologies in 2025 herald a significant transformation in manufacturing processes. One of the foremost advantages of these state-of-the-art solutions is their enhanced precision. With the integration of AI-driven automation, the welding process achieves unparalleled accuracy, minimizing defects and enhancing product quality. This evolution not only streamlines production lines but also reduces material wastage, leading to cost efficiencies that are critical in today's competitive landscape.

Moreover, the robustness of the new welding technologies ensures long-lasting durability in the products manufactured. These advanced solutions facilitate superior bond strength, which is crucial in various applications ranging from electronics to automotive sectors. Additionally, the ability to perform rapid welding cycles significantly boosts productivity, allowing manufacturers to meet increasing market demands without compromising quality. As businesses embrace these innovations, they position themselves at the forefront of their industries, ready to capitalize on the benefits of cutting-edge technology while ensuring sustainability and efficiency.

In today's rapidly evolving industrial landscape, selecting the right welding solution is crucial for maximized efficiency and quality. The diverse range of available technologies each offers unique advantages, tailored to specific applications. For instance, traditional MIG and TIG welding solutions provide superior control and versatility, making them ideal for intricate designs. On the other hand, advancements in robotic welding significantly enhance production speed and accuracy, accommodating high-volume manufacturing demands.

When comparing welding solutions, consider the key features that matter most to your operational needs. Cost-effectiveness, ease of use, and maintenance requirements are critical factors that can influence your decision. Additionally, newer technologies such as laser welding are gaining traction due to their precision and lower thermal distortion, which can help improve overall project quality.

**Tips:** Focus on training your team on the nuances of each welding type to maximize productivity. Regular maintenance checks can also prevent unexpected downtime and prolong the life of your equipment. Lastly, consider investing in solutions that integrate seamlessly with existing CNC systems for enhanced operational efficiency.

Tab welding methods have evolved significantly, with various applications across multiple industries. In the automotive sector, tab welding is crucial for the assembly of battery packs, ensuring reliable connections that enhance performance and safety. Similarly, in the electronics industry, precise tab welding techniques are employed to create compact and efficient interconnections, facilitating the production of smaller devices with improved functionality. The advancements in laser welding and ultrasonic welding have further refined these processes, increasing production speed and reducing material waste.

When choosing a tab welding solution, consider the specific requirements of your application. For instance, laser welding offers exceptional control and precision, making it ideal for delicate components. Ultrasonic welding, on the other hand, is advantageous in environments where speed and efficiency are paramount. Investing in the right technology can lead to significant improvements in product performance and operational efficiency.

Additionally, always ensure that your welding equipment is regularly maintained and calibrated to achieve optimal results. This practice not only extends the life of your machinery but also enhances the quality of your welds. Emphasizing training for your workforce on different tab welding methods can also lead to better outcomes and fewer production errors.

The welding industry is undergoing a significant transformation due to innovative materials and techniques that are shaping its future. Ultrasonic welding, for instance, is emerging as a leading method due to its ability to join dissimilar materials with remarkable precision and minimal thermal input. This technique not only enhances the mechanical properties of the welded components but also reduces production costs and cycle times, making it a highly efficient solution for various applications.

In addition to advanced welding techniques, the integration of digital and virtual technologies into welding training is revolutionizing education in this field. VR simulators and digital platforms provide a safe and interactive environment for trainees to practice their skills without the risks associated with traditional methods. This approach not only improves safety and efficiency but also paves the way for next-generation certification processes, ensuring that future welders are well-equipped to meet the demands of an evolving industry. As these innovations continue to unfold, the welding landscape is poised for significant advancement.

In recent years, the focus on sustainability within the manufacturing sector has garnered significant attention, particularly in tab welding practices. The incorporation of eco-friendly materials and processes can greatly reduce the carbon footprint associated with traditional welding techniques. A report by the International Energy Agency (IEA) revealed that industrial processes account for approximately 24% of global energy-related CO2 emissions. As manufacturers adopt innovative welding solutions in 2025, it is anticipated that environmentally responsible practices will play a pivotal role in minimizing these emissions.

Modern tab welding solutions are not only focused on efficiency and performance but also on sustainability. For instance, using laser welding technology can minimize energy consumption by up to 90% compared to conventional methods, according to a study by the American Welding Society. Additionally, advancements in automation and robotics in welding processes reduce material waste significantly, ensuring a more sustainable production cycle. By leveraging these innovations, companies can align their operations with the growing demand for sustainable manufacturing while enhancing their competitiveness in the marketplace. As we move further into 2025, the emphasis on sustainability in tab welding will likely shape industry standards and practices moving forward.