Leave Your Message

In recent years, the demand for high-performance energy storage solutions has surged, with the 18650 Battery Pilot Line emerging as a critical focus for manufacturers aiming to enhance efficiency and output in battery production. According to a report by the International Energy Agency (IEA), global lithium-ion battery demand is projected to reach 1,200 GWh by 2030, necessitating advancements in manufacturing methodologies. The 18650 battery, widely utilized in electric vehicles (EVs) and consumer electronics, exemplifies this trend, leading to increased investments in pilot lines designed to streamline production processes. A comparative analysis of various pilot lines reveals significant disparities in throughput and energy efficiency, underscoring the importance of optimizing these systems to meet the anticipated market growth. By examining key performance indicators across contemporary manufacturing practices, this analysis aims to shed light on the evolving landscape of 18650 battery production and its implications for future energy solutions.

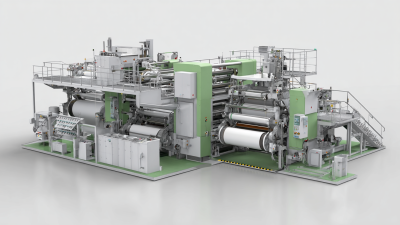

The production of 18650 batteries has undergone significant transformation over the years, reflecting the rapid advancements in manufacturing technologies and processes. Initially, the production methods relied heavily on manual assembly and rudimentary quality control measures, which often led to inconsistencies in output and performance. However, with the advent of automation and advanced robotics, modern facilities have shifted towards streamlined operations that prioritize both efficiency and precision. These changes have not only enhanced production speed but have also minimized human error, resulting in higher quality products.

Furthermore, the evolution of materials used in the manufacturing of 18650 batteries has played a crucial role in improving overall output. Modern production methods now incorporate advanced materials that are lighter, more durable, and offer better performance characteristics. Additionally, state-of-the-art testing techniques enable manufacturers to assess battery performance in real-time, ensuring that each unit meets stringent safety and efficiency standards before reaching the market. As manufacturing practices continue to evolve, the 18650 battery production line stands out as a benchmark for how technology can reshape traditional industries.

| Production Method | Efficiency (%) | Output (Units/Day) | Energy Density (Wh/kg) | Cycle Life (Charging Cycles) |

|---|---|---|---|---|

| Traditional Assembly | 85 | 5000 | 200 | 300 |

| Automated Process | 92 | 8000 | 250 | 500 |

| Lean Manufacturing | 90 | 7500 | 220 | 400 |

| Smart Manufacturing | 95 | 10000 | 280 | 600 |

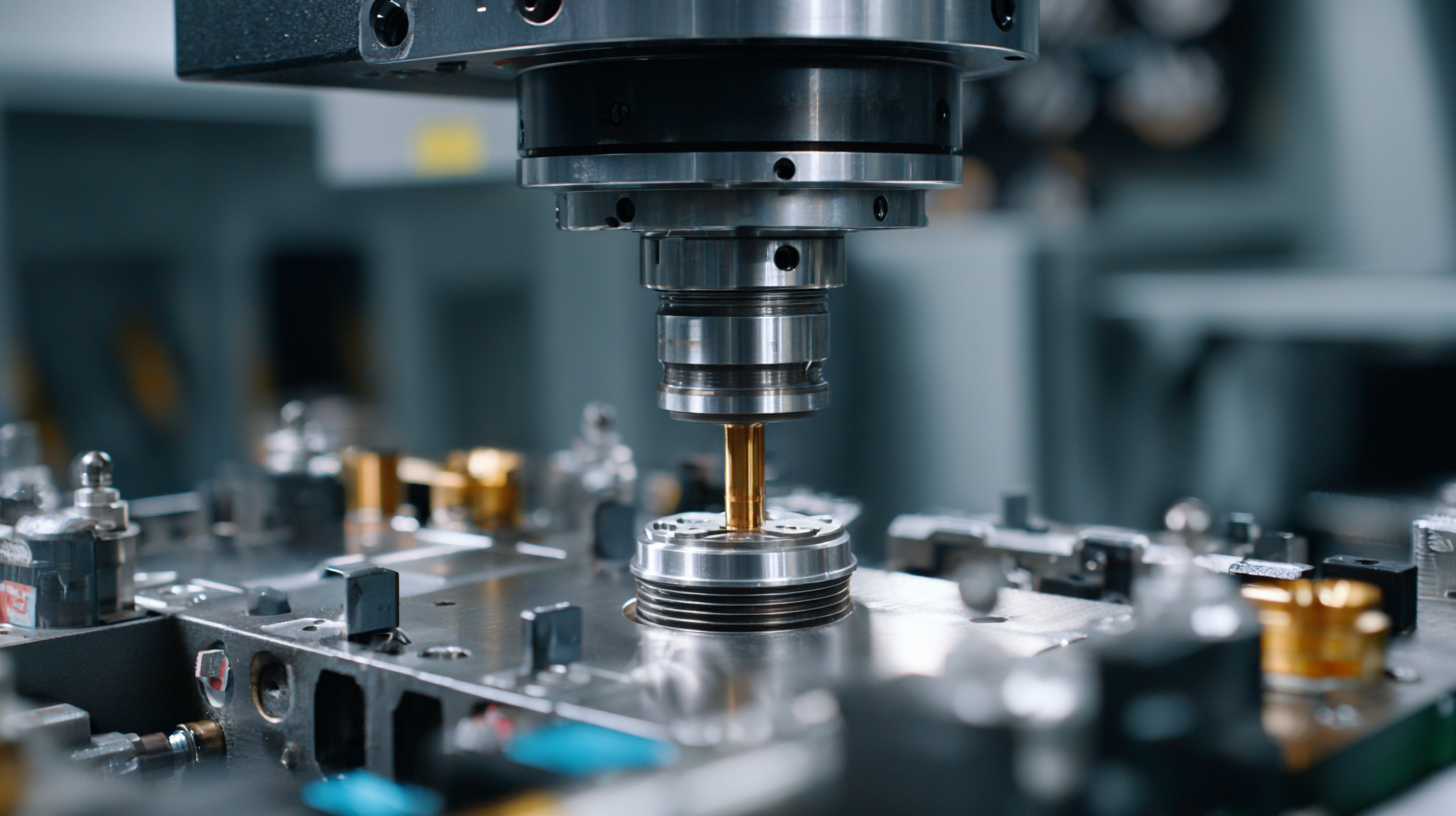

In the ever-evolving landscape of battery manufacturing, the efficiency of production lines plays a critical role in deciding not only the cost but also the output quality. A comparative analysis of 18650 battery pilot lines reveals various key performance metrics that organizations can utilize to gauge their operational effectiveness. Metrics such as cycle time, yield rate, and energy consumption have become standard in evaluating the efficiency of manufacturing processes, helping manufacturers identify areas for improvement.

Cycle time, for instance, is a fundamental metric that indicates how quickly a battery can move through production phases. Shortening this time can lead to increased output without compromising quality. Additionally, the yield rate, which measures the number of usable batteries produced compared to the total produced, reflects the effectiveness of the manufacturing process. A high yield rate indicates that a line is optimized both in terms of machine operation and quality control. Lastly, monitoring energy consumption is vital, especially with the rising demand for sustainable manufacturing practices. Keeping energy use in check not only lowers costs but also aligns with global sustainability goals, making these performance metrics indispensable for manufacturers aiming to stay competitive in the battery market.

In the rapidly evolving landscape of battery manufacturing, the 18650 format remains a significant player despite the emergence of newer alternatives like the 21700 Li-ion cells. A comparative analysis reveals interesting distinctions between these two cell formats in terms of electrochemical, thermal, and geometrical properties. The common 18650 cell, known for its versatility and established presence, is often contrasted with the larger 21700 cell, which promises improved energy density and efficiency.

When evaluating pilot lines for 18650 battery production, efficiency and output become critical parameters. Data from pilot lines operating under specific conditions, such as cycling at 1C and 25°C, indicate that while 18650 cells offer reliable performance, the advanced designs of the 21700 cells could potentially reshape output metrics in manufacturing processes. The implications of these differences extend beyond raw performance – they also challenge manufacturers to rethink production methodologies and invest in technologies that can enhance yield and reduce costs without compromising quality. As the industry strives for better solutions, the interplay of these technologies will define the future of battery production.

The production of 18650 batteries, widely used in laptops, electric vehicles, and portable devices, faces significant challenges in modern manufacturing. One of the primary obstacles is the need for increased efficiency amidst rising demand. According to a recent report from the International Energy Agency (IEA), global demand for lithium-ion batteries is expected to grow by up to 40% annually over the next decade. This surge necessitates innovations in manufacturing processes to optimize throughput and reduce costs, as traditional methods struggle to keep pace.

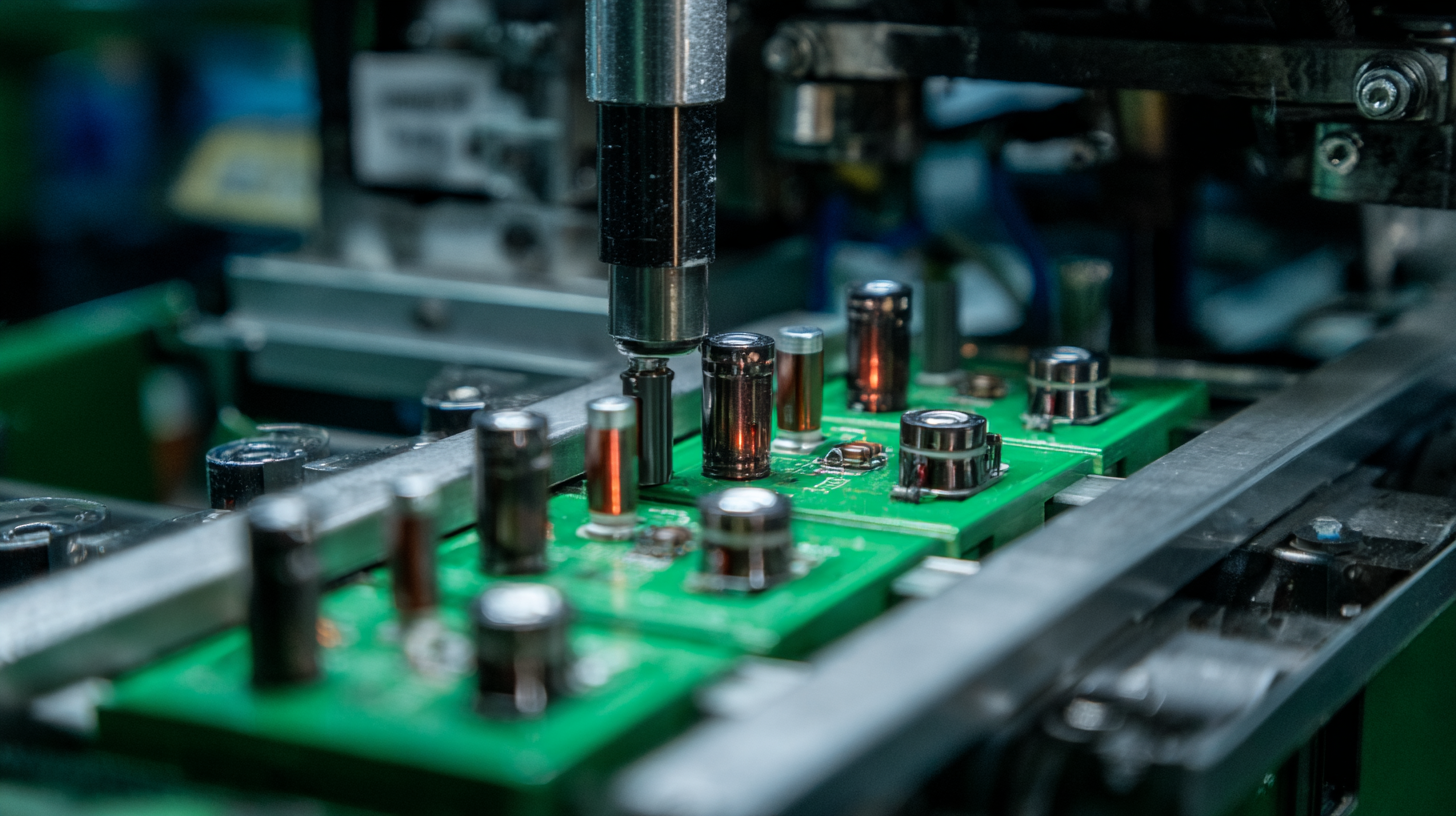

Innovations such as the implementation of automated assembly lines and advanced quality control systems are essential for overcoming these production bottlenecks. For example, a study by Research and Markets indicates that integrating robotics in battery production can enhance output by 25%, while significantly minimizing defects. Moreover, smart manufacturing solutions leveraging IoT technology are beginning to transform workflow efficiency. By employing real-time data analytics, manufacturers can identify inefficiencies and adjust their processes dynamically, leading to a more responsive and sustainable production model. These advancements not only aim to address current challenges but also set the stage for a more robust future in the 18650 battery industry.

As the demands for energy storage continue to rise, the future of 18650 battery manufacturing holds immense potential for innovation. One evolving trend is the integration of automation and advanced robotics into production lines. This shift not only enhances efficiency but significantly reduces human error, leading to more consistent product quality. Companies are investing in smart manufacturing technologies that employ machine learning and artificial intelligence to optimize processes, from cell assembly to final packaging.

Moreover, sustainability is becoming a key focus in the development of 18650 batteries. Manufacturers are exploring eco-friendly materials and recycling processes to minimize environmental impact. The adoption of circular economy principles ensures that the resources used in battery production can be reused or repurposed, thereby reducing waste. This trend not only meets regulatory demands but also caters to an increasingly environmentally conscious consumer market. As these techniques evolve, the 18650 battery sector is poised to achieve remarkable advancements in both efficiency and output, paving the way for a greener future.